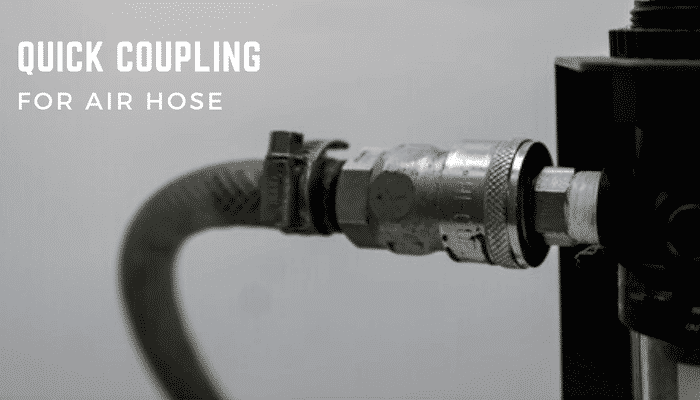

What Is Quick Coupling or Quick Connect Coupler?

Quick couplings are also known as quick connect couplers. These are general purpose couplings that can connect at either end of the connection.

Quick couplings can be connected and disconnected easily as they are compact but very robust and sturdy in their application. They are highly reliable as they provide unswerving service for the transfer of fluid for pneumatic, hydraulic and vacuum systems.

The couplings on the flow side have a floating ball valve that closes automatically when the couplings are disconnected and hence prevent the spillage of fluid from the system.

They are generally designed according to the maximum working pressure and could be made of steel, brass or stainless steel depending upon the application and the type of fluid.

The major applicable fluids are air, oil and water. Specific grades of hydraulic oil, fuel oil and lube oil could be used as well for the same.

These couplings can become sluggish over a long time and might pick up rust due to the nature of the fluid being transferred and hence extreme care must be taken when they are removed from the pressurized system.

Simple hack – These couplings must once be put in diesel oil after removal for the smooth functioning of the ball float and the small steel balls which form the part of the mechanism.

All the main engine and auxiliary engine hydraulic tools are connected by high-pressure hydraulic hoses joined by quick couplings which are robust and have a high strength to witness such high pressure ranging from 0-2500 bars or higher.

These couplings must be checked for their operation before the system is pressurized to prevent unwanted injuries.

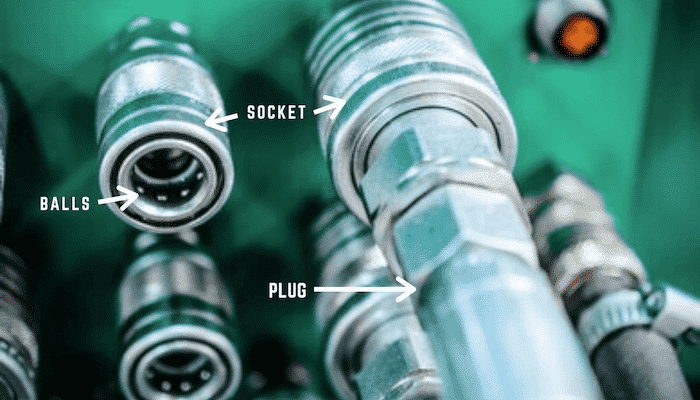

After connecting couplings, they must be rotated to check their proper connection. The coupling heads rotate on the balls inside the coupling and hence ensure their perfect connection.

The couplings basically have two parts mainly – a socket and a plug.

The socket is a male part of the coupling and the plug being the female part.

The quick couplings are of various types, such as:

Single End Shut Off Coupler

As the name suggests, these couplings shut off only one side of the coupling, mainly the socket side i.e. male part and hence prevent the leakage of the fluid.

These couplings are low-pressure couplings used mainly for air, oil and water with a maximum pressure of 20 bars. They also have a similar ball float which snaps shut the flow as soon as they’re disconnected.

These are available in variety of sizes, again depending on the application.

Single End Shut Off Coupler can further be of many types, such as

- Hose End Type

- Male Thread Type

- Female Thread Type

Double End Shut Off Coupler (Standard Pressure)

This type of couplings shut off both (instantaneously), the socket and the plug upon disconnection. They can be of brass, stainless steel or steel with different pressure ranges, sizes and applications of fluid.

Double-end shut off couplers are used in standard pressure applications with a maximum working pressure of 100 bars.

Normal Working Pressure – 20 bars

Maximum Working Pressure – 100 bars.

Double End Shut Off Coupler (High Pressure)

They are generally recommended for high-pressure applications of compressed air, hydraulic and water systems. The steel used to make these couplings is special annealed steel for higher strength and reliability. Similarly, both the sockets and plugs are closed by an inner valve when they are disconnected.

The high pressure that they can withstand depends upon the size of the main body.

Normal Working Pressure – 210 bars

Maximum Working Pressure – 215 bars

Double End Shut Off Coupler (Ultra High Pressure)

These are only for high-pressure hydraulic oil applications. They have a ring lock device that provides extra safety against shock and vibration. They have very high reliability against leakage as well.

Normal Working Pressure – 700 bars

Maximum Working Pressure – 2500 bars

Line Couplers

Line couplers are generally used to connect two or more couplings simultaneously to a single line. They are used in hydraulic couplings of cylinder heads of the main engine and auxiliary engine onboard.

QCDC Coupling:

This is another form of quick coupling used for the transfer of cryogenic liquid such as LNG etc. QCDC stands for “quick connect disconnect”.

Thus, these types of couplings are efficient, reliable, easy to connect and of great use in modern-day to day operations on-board a ship.

Disclaimer: The authors’ views expressed in this article do not necessarily reflect the views of Marine Insight. Data and charts, if used, in the article have been sourced from available information and have not been authenticated by any statutory authority. The author and Marine Insight do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendation on any course of action to be followed by the reader.

The article or images cannot be reproduced, copied, shared or used in any form without the permission of the author and Marine Insight.

Do you have info to share with us ? Suggest a correction

Latest Marine Technology Articles You Would Like:

- 10 Harmful Effects Of Impure Air On Ship’s Machinery

- 10 Important Things to Check While Starting Fuel Oil Purifier on Ships

- 10 Noteworthy LNG-Powered Vessels

- 10 Points for Efficient Turbocharger Operation On Ships

- 10 Practical Tips to Handle Engine Room Pumps

- 10 Precautions to Take Before Operating Controllable Pitch Propeller (CPP) on Ships

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Web Stories