Methanol Superstorage Solution On Existing Ships Gets Approval In Principle

A new and space efficient retrofit methanol storage solution from SRC Group has received Approval in Principle from Lloyd’s Register, signifying that no major conceptual issues have been identified as standing in the way of its securing classification approval and regulatory compliance.

Methanol Superstorage offers the potential for ships with years of service ahead to be considered for transition to a marine fuel established as a frontrunner for meeting IMO targets to cut greenhouse gas emissions from ships by at least 20% by 2030 and 70% by 2040 (against a base year of 2008). Other technologies, such as hydrogen fuel and carbon capture, will take some years to mature before they can help meet IMO’s net-zero target for around 2050.

Clarksons reported 14% of tonnage on order as methanol-capable earlier this year, compared to a 22% share for liquefied natural gas. The analyst has estimated that 1,200 ships could be powered by methanol by 2030.

However, while renewably-sourced methanol fits the net-zero framework, and is fairly easy to store and handle, it takes twice as much to generate the same energy as HFO. On board ship, this is a major storage issue, especially because low flashpoint fuel tanks conventionally require cofferdams.

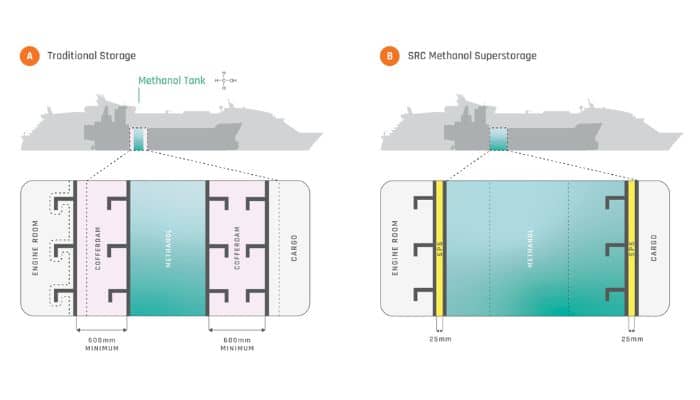

Although space penalties can be addressed in newbuild ship design, even the youngest existing ships were not built with retrofitting methanol in mind. Methanol Superstorage avoids cofferdams by constructing tank walls using Sandwich Plate System Technology, in a solution boosting volume by up to 85%. The extraordinary gain can be retrofitted with minimal impact on the general arrangement.

“Due to long-established use in other industries, availability and performance, methanol is the alternative marine fuel offering the strongest potential to reduce ship GHGs at pace,” said Hannes Lilp, CEO, SRC Group. “Methanol Superstorage reinvents methanol storage using the proven SPS Technology system. Instead of a cofferdam which extends – at least – to 600mm, the solution uses a 25mm thick SPS barrier to protect the tank from fire and as a triple barrier against leakage.”

Engineering, Procurement, Construction and Installation (EPCI) service provider SRC Group, whose experience in complex maritime and offshore refits extends across over 5,000 projects, developed Methanol Superstorage to ensure that existing ships play a full part in energy transition, he said. AiP for its supporting design documents opened the way for wider scrutiny of a concept which, subject to statutory approval, would be decisive in making methanol a mainstream fuel for existing ships.

The SPS Technology Sandwich Plate System is a permanent, A60 fire rating certified structural composite, used in maritime and offshore applications for over two decades and approved by all major IACS class societies across a range of applications.

AiP from LR relates specifically to ships outlined in Part G of SOLAS Ch. II-1. SRC would deliver EPCI services, fully integrating the new solution “from the bunkering station to the high-pressure pump,” said Lilp.

Press Release

Disclaimer :

The information contained in this website is for general information purposes only. While we endeavour to keep the information up to date and correct, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability or availability with respect to the website or the information, products, services, or related graphics contained on the website for any purpose. Any reliance you place on such information is therefore strictly at your own risk.

In no event will we be liable for any loss or damage including without limitation, indirect or consequential loss or damage, or any loss or damage whatsoever arising from loss of data or profits arising out of, or in connection with, the use of this website.

Disclaimer :

The information contained in this website is for general information purposes only. While we endeavour to keep the information up to date and correct, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability or availability with respect to the website or the information, products, services, or related graphics contained on the website for any purpose. Any reliance you place on such information is therefore strictly at your own risk.

In no event will we be liable for any loss or damage including without limitation, indirect or consequential loss or damage, or any loss or damage whatsoever arising from loss of data or profits arising out of, or in connection with, the use of this website.

Do you have info to share with us ? Suggest a correction

About Author

Marine Insight News Network is a premier source for up-to-date, comprehensive, and insightful coverage of the maritime industry. Dedicated to offering the latest news, trends, and analyses in shipping, marine technology, regulations, and global maritime affairs, Marine Insight News Network prides itself on delivering accurate, engaging, and relevant information.

About Author

Marine Insight News Network is a premier source for up-to-date, comprehensive, and insightful coverage of the maritime industry. Dedicated to offering the latest news, trends, and analyses in shipping, marine technology, regulations, and global maritime affairs, Marine Insight News Network prides itself on delivering accurate, engaging, and relevant information.

Related Articles

Daily Maritime News, Straight To Your Inbox

Sign Up To Get Daily Newsletters

Join over 60k+ people who read our daily newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

BE THE FIRST TO COMMENT