How Shipyards Can Adopt Advanced Outfitting?

In the previous article of this series, we explained the concepts that are used in advanced outfitting. However, in order to understand the entire strategy to its completion, we must now expand our viewpoint.

Shipyards that implement advanced outfitting have special facilities required to allow this method to be applied efficiently, in order to obtain maximum benefits.

The following are the factors that are to be considered by the shipyards in order to adopt advanced outfitting:

Overall Layout of the Shipyard

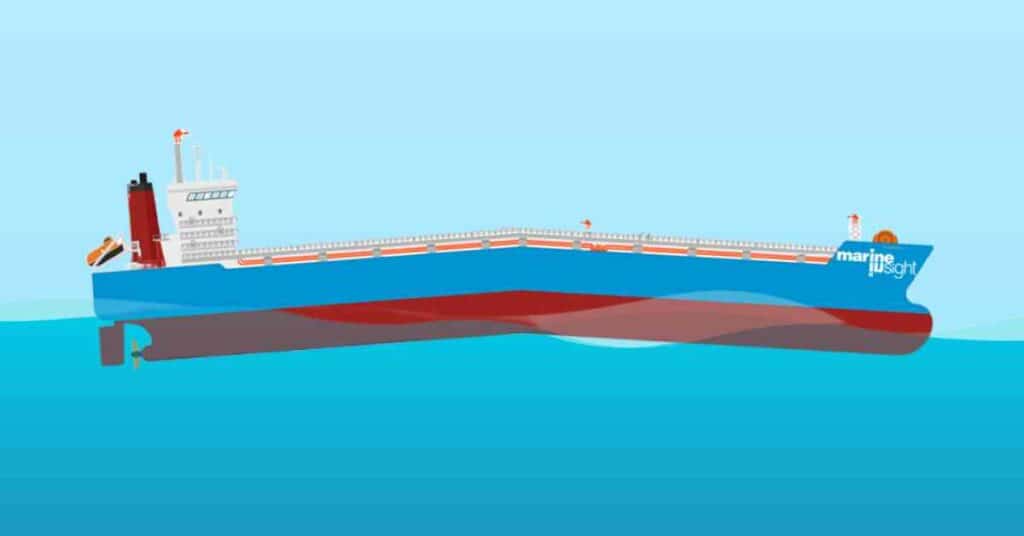

If an old shipyard is to be upgraded into a facility that can adopt advanced outfitting, then the layout of the shipyard needs to be re-designed. The layout of the yard includes the location of the steel complex (where the steel plates are stores, hull shops, and fabrication workshops), outfit shops and areas to be relocated in such a manner so that the flow of the building work is sequential, and there is less requirement to move material and labour force from one shop to another. If the ships are built and erected on berths, then the berths are to be properly strengthened so that they can carry the loads of the hull and machinery together, because in conventional shipbuilding, the outfits are generally added after the ship is launched.

If a new shipyard is to be established for advanced outfitting, the layout of the yard is to be very intricately planned so that the storage of materials (for example: steel plates), fabrication of the hull blocks and units, outfitting areas are in close proximity to the building docks. Also, proper cranage facilities are to be provided in all the areas, such that they are suitable weight of the maximum size of blocks (weight including that of steel hull and machinery) fabricated in the yard. Adequate mobile cranage facilities are also to be provided for transportation and erection of blocks within the building docks.

Design Department adapted with Advanced Outfitting

The design department in an advanced shipyard should also be adept with design techniques that suit the strategy of advanced outfitting. Do you see, how we have slowly shifted from the production site to the design department? This should convey a very important message to you. Shipbuilding is a very integrated industry, where the operation of one single department is intricately connected to many other department, and also some other industries.

Normally, in conventional shipbuilding processes, the design drawings are made system-wise. For example, there would be a separate drawing for all the engine room systems. Now, such drawings are not feasible in case of advanced outfitting, because in this case, the hull fabrication goes hand in hand with the erection of machinery and outfit. So the design department must prepare the drawings in order to align them with the work structure of the yard.

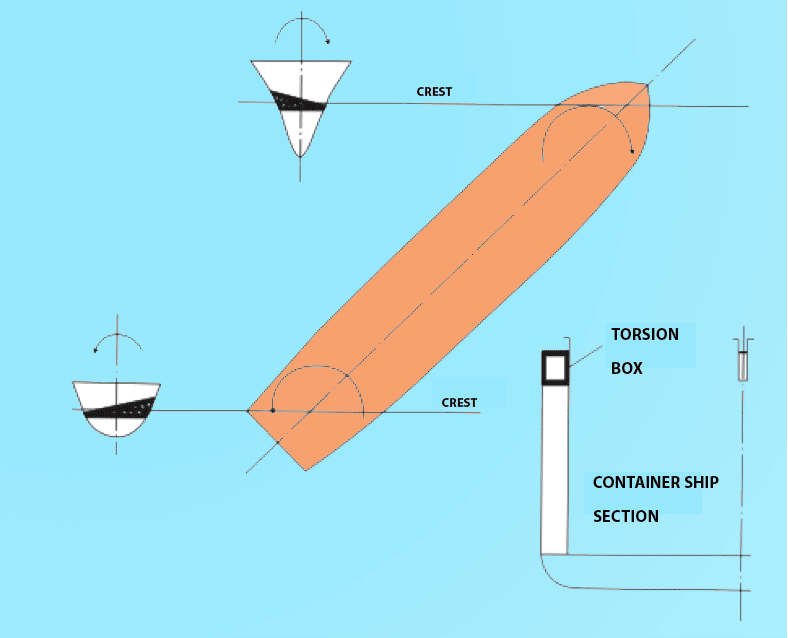

If you remember that we had discussed about the system of building the hull in form of blocks, you would appreciate how the design process is oriented in order to carry out block erection. Now, the number and size of the blocks is to be decided by the designer, depending upon the cranage facilities, and the yard capacity. So, from the beginning, the hull structure is broken up into the required number of blocks, and design for the blocks are carried out, keeping the process of outfitting in mind.

Along with the drawings, a list of materials is to be mentioned clearly that are required to fabricate the particular block. The materials would include everything including components of hull structure, to machinery and other outfit items. This is done, so that the production department can easily concentrate on the work content of a particular block at a particular time.

Remember the concept of Group Technology (workstations), that we had seen in the last part of this series? Well, if group technology is proposed (which is mostly carried out in Japanese and Korean shipyards), the drawings are to be prepared basing on the trades available in each workgroup, so that the work can be processed smoothly in each workstation.

Proper work instructions are also to be indicated in the drawings, for reducing the production time. If blocks are to be turned upside down for carrying out downhand welding, or for laying out pipelines and ventilation trunks or cables, proper instructions for all these processes are to be provided along with the drawing for each of these blocks.

Proper Planning of Material Procurement in Yard

The name of this topic may not appeal much to you. But it is in this aspect of shipbuilding, that the dynamics of the entire yard economies lies. How? The answer is simple. Steel cost changes with time. So, the planning department needs to cleverly analyse the cost trends and procure the material at the suitable time intervals, also keeping in mind, that the production schedule is not hampered.

In order to understand further, let us first acquaint ourselves with a new term- Master Schedule. A Master Schedule, is a routine timeline prepared by the planning department, which specifies all the activities involved in the process of building a particular ship, along with their assigned dates of commencement, and completion. So, depending on the master schedule of a particular project, the planning department prepares a schedule for completing individual blocks, along with associated outfitting.

Depending on the above prepared schedule of fabrication of blocks and associated outfitting equipment, the machinery and materials are to be procured, so that they are readily available to the production departments ‘before’ the outfitting for the particular block starts.

Marshalling of Materials to outfitting areas

For advanced outfitting to be carried out without bottlenecking the production processes, proper infrastructure and trained manpower are to be provided to marshall the materials and machinery required to outfit the concerned blocks of the hull. The design drawings shall also specify the operations to be carried out during marshalling, in a chronological order, which is to be followed by the yard.

Lastly, it is important to know at this stage of our discussion, that facilities for outfitting of accommodation blocks are completely different from that of other blocks, in the recent shipbuilding industry. These are most of the times, prepared by sub-contractors whose construction standards satisfy those of the classification societies. Once these blocks come prepared into the yard, outfitting of accommodation blocks involves separate technology. So they are many times also outfitted by the subcontractors’ teams themselves, in parallel to the building of the corresponding hull blocks.

By now, you must have had a clear idea of what facilities in the yard enable the smooth operation of advanced outfitting, in order to cope up with the low cycle time requirements in the recent shipbuilding industry. The last, and most interesting aspect of this series shall be discussed in the next and last part, where we will delve into the different advantages of advanced outfitting.

Over to you..

Do you have more information on advanced outfitting?

Let’s know in the comments below.

Do you have info to share with us ? Suggest a correction

Latest Naval Arch Articles You Would Like:

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.