Management And Procurement Of Spares On Ships – How To Identify, Order And Reduce Costs

The shipping industry has changed over the period of time in almost every aspect.

From regulations monitoring sulphur content to procurement and management of spares, this is one of the only industries which runs economies and needs regular monitoring and improvisation to meet the fast-growing needs.

Spares in the shipping industry is a major domain of business, expanding at an exponential rate, saturating the market and increasing competition for existing traders or manufacturing companies.

In this article we will try to know more about the following topics:

1. Identification of spares.

2. Supply chain of spares.

3. Procurement of spares, prioritizing, planning and cost reduction.

Identification of spares

To identify a spare part there are different methods used onboard ships, which are as follows:

1. Part number

The part number is the basic number of any part mentioned in a particular drawing of any machinery. We might often confuse part number with the item number or drawing number, which might lead to wrong procurement.

We need to understand that the manual for the same type of machinery with a different model with the same part number might be different.

So if we ever raise a requisition with only part number, either the supplier will require the ESN (engine serial number), model, manual page of specific machinery with every possible information to make sure that the supplied spare is correct.

2. Drawing number

Drawing number is the sum total of all the parts of a particular machine or a section of a machine in one single drawing.

This is also an important aspect to know the spare required as many manufacturers with time keep updating their machinery manuals, which in turn might lead to a change of drawing number.

This might help the supplier understand without ESN the range serial number in which this specific machine falls in. Drawing number can be better understood with the following examples below.

3. Item number or position number

This is often mentioned in some manuals to give numbers to different parts in a single drawing to ensure correct procurement of spares since there will be no confusion in supplying if a particular number is stated with the same name.

For eg: a drawing with 5 same names of nut might not have the same nut for each position, it might be M24 or M16 or any other nut.

This is because different suppliers across the world have a different language which in turn could be misunderstood.

4. Material number

This is a special number generated by the manufacturer for supply and keeps the business in close walls and ensures correct supply.

If the material number of two items is the same, then these two items are exactly similar to each other without the need of part number, drawing number or item number.

Material number, in short, is the king of all the methods of identification of spares, but often not shared to ensure pilferage of trade secrets.

5. Specifications/ Description/ Details

These are often required in cases where the drawing number, part number, or item number is not sufficient to describe the spare.

Some spares might not be mentioned with sufficient details in the drawing or might be different for any specific machinery, which in turn could cause wrong delivery.

Details might include, dimensions, ampere, Kw, Frequency, volts, material, design, etc.

6. IMPA catalogue

This catalogue is the go-to resource for all spares available for shipping Industry, majorly to procure consumables required in a ship. Nuts, bolts, plugs, valves, tubes, pipes, tools, contactors, fuses, etc. we name it and they have it, only it is not ship specific.

An IMPA number mentioned in a requisition would not lead to any confusion and will ensure correct delivery of a spare with no further questions.

7. Article number

This is a varied term which could have different names but have the same concept.

Most of the shipping companies these days have started a new method of procurement of spares in which they have created their company-specific numbers to identify a particular spare, any spare with same article number will be same for a particular company.

If we see in a broader aspect, article number is nothing but a material number for traders and shipping companies to create a database of their own. This number is of complete irrelevance to any other association.

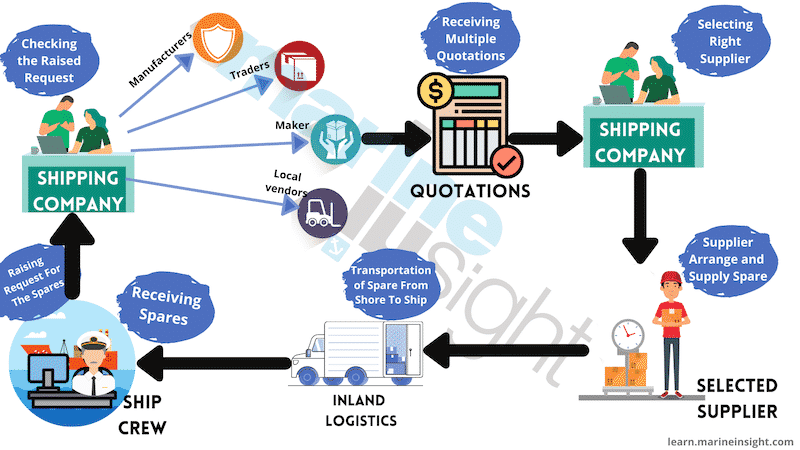

Supply Chain of Spares

Supply of spare to a ship comprises of few steps which are almost standard around the world.

Once the ship raises a requisition mentioning requirement of specific spare or a consumable, the respective company post confirming budget for that ship confirms if the spare will be supplied in the next store’s supply, except it is a critical spare or a consumable or any spare required on breakdown for immediate replacement.

The requisition is raised by the ship staff through identification methods mentioned above.

Once the requisition is confirmed, the enquiry is sent to several traders, manufacturers, maker or local vendors, depending upon the type of spare.

A consumable is usually preferred through local orders, which shall be discussed later in section 5.

The quotations once received from suppliers is compared on the basis of cost and lead time (time required for the trader or manufacturer to get it in their warehouse if the balance is zero).

Traders or Manufacturers usually keep a minimum balance of every spare to ensure immediate supply, only if the demand is higher than the current stock of the supplier they will mention lead time for balance spares.

Once the specific supplier meets the requirement of the company on the basis of cost and lead time, they send an order confirmation mentioning the same or revised quantity of spares they want to order.

Purchase order along with the airbill number and details are sent post-credit of the amount to the supplier.

Many companies have postpaid or prepaid deals with their supplier depending upon the past relations between the two.

The spares are now in transit to be sent on board which includes the cost of the spare, taxes required as per supplier and receiver’s country laws and transportation charges.

Procurement of Spares, Prioritizing, Planning and Cost Reduction

Procurement of spares is quite a competitive, huge and complicated business in the shipping industry, considering the increasing number of fleet and the cost involved. It’s the second most important cost after bunkers for running a ship.

The method mentioned above may have a mediator between the supplier and the ship’s company.

A trader or couple of traders marking their profit on a transaction.

This is because many big or small manufacturers like BOSCH, SKF, Mcgregor, Alfa Laval etc, give trade license to different traders to enhance their reach to different sections of the world.

The cost involved reduces drastically for a spare if the ordered is in bulk. This can be better understood by the example below:

A Nozzle required on an engine has a cost of EUR 250 for a 6 piece, whereas cost might be 200 EUR for 50 pcs.

So a ship requiring spare from the manufacturer in Europe will spend 250X6=1500+ taxes+ Transportation charges, whereas if the same manufacturer has a trader in Singapore, with a minimum stock of 50 pcs bought at a cost of 200, marking its profit of 30 EUR on each, would quote 230×6=1380+taxes, transportation charges and reduced cost reap the profit to both ends as well as the flow rate of the manufacturer is taken care of.

A spare can be prioritized on the basis of its cost, lead time and location of supplier and receiver.

Mariners often complain about the delayed delivery of spares but at the same time, the company managing these spares are bound by several factors of budget and cost control.

Certainly, if it’s a critical spare required onboard Eg: Filter for OWS, there is no delay in supply.

Exhaust or inlet valve seats, for example, might have a larger lead time and if a major overhaul is expected in next quarter, the company placing an order will wait for the lead time by a supplier supplying at a lower cost instead of heading for immediate delivery at surged prices.

To control cost, a huge margin of profit could be made if ample knowledge is available for procurement of spares from different vendors and shifting to local orders for consumables.

Many spares are easily available if we know the correct specifications to identify for the suitability of the same, ensuring we do not bypass the legit guidance from machine manufacturer to use any alternate spare.

This can be understood by the example below.

For instance, MGPS has anodes which will deteriorate at a time interval specified from the manufacturer, so are anodes of the pump.

If a ship is vigilant enough to foresee the requirement of a particular spare in advance, it will help the purchaser to have a required lead time in hand to procure the same item at a much lower cost.

Generally longer the lead time lower is the price.

The pumps on board a ship are categorized in two manuals from the yard, centrifugal pumps and Positive displacement pumps.

Unfortunately, the pump manufacturer often doesn’t mention the kind of bearings installed in each pump which in turn will cost much higher if ordered through the pump manufacturer, excluding instances where the bearings are specific and could not be identified. We can always order from local vendors bearings of SKF, NSK, FKM etc. according to size and type.

This surely would reduce the cost, since local orders are often cheap. Same goes for nuts and bolts, valves, gaskets, carpets.

In some cases, a shipping company with same machinery or sister ships on the same route of the port of calls can ask for any spare to be landed on any specific port for its sister ship to be supplied, for example, FIVA valves on ME engines.

This actually increases the number of available spares in a specific time frame at a particular location under the control of the same company.

The most important thing to note to reduce losses in spare trading or purchasing is to make sure the correct spare is being ordered, packed and delivered.

Since the transportation cost sometimes is higher than the spare itself, wrong details will lead to very high losses for a mistake, which can be controlled with micro monitoring of every detail.

Since the transportation charges are high the wrong spare is nothing but a scrap onboard which is never used or has to be scrapped.

Disclaimer :

The information contained in this website is for general information purposes only. While we endeavour to keep the information up to date and correct, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability or availability with respect to the website or the information, products, services, or related graphics contained on the website for any purpose. Any reliance you place on such information is therefore strictly at your own risk.

In no event will we be liable for any loss or damage including without limitation, indirect or consequential loss or damage, or any loss or damage whatsoever arising from loss of data or profits arising out of, or in connection with, the use of this website.

Do you have info to share with us ? Suggest a correction

Disclaimer :

The information contained in this website is for general information purposes only. While we endeavour to keep the information up to date and correct, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability or availability with respect to the website or the information, products, services, or related graphics contained on the website for any purpose. Any reliance you place on such information is therefore strictly at your own risk.

In no event will we be liable for any loss or damage including without limitation, indirect or consequential loss or damage, or any loss or damage whatsoever arising from loss of data or profits arising out of, or in connection with, the use of this website.

Related Posts

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.