What is Extended Dry-Docking of Ships?

According to SOLAS regulation, every sea-going vessel has to undergo two dry docks within a period of 5 years. A ship in dry dock is a ship out of service. Dry dock is a complex process which is both expensive and time consuming. It is a necessary evil which ship owners, operators, and crew members have to go through when the time requires. With two compulsory dry docks within a period of 5 years, it is a stressful task for ship owners and personnel who have to go through a lot of planning and preparation for the drydocking activity.

Planning of dry docking starts several months before the scheduled date. A number of things needs to be arranged starting from the convenient place for dry-docking to arranging spares and on-shore maintenance staff. Moreover, it is often seen that ships have to take a totally different route for a suitable dry dock place as most of the time the desired facility is not available when needed. This is very common with larger vessels.

In order to deal with this situation, all major classifications societies have a special program called the “Extended Dry-Docking” or EDD scheme.

What is Extended Dry-Docking Program?

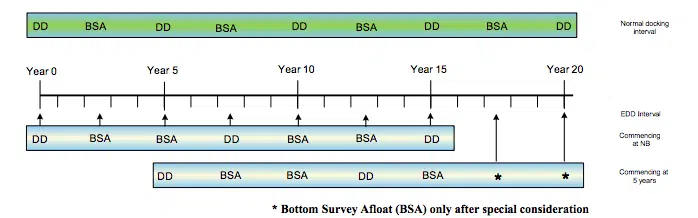

Under extended dry-docking program, ships have a privilege to extend their dry docking period from 5 to 7.5 years. This means that ships under this special program gets maximum dry dock interval of 7.5 years by replacing certain dry-dockings by in-water surveys (IWS) which are carried out by approved diving companies. A variety of factors are taken into consideration before approving a ship for extended dry-docking.

However, not every ship is allowed for the extended dry-docking program.

Image Credits: DNV

One of the major benefits of Extended Dry-docking program is that the ship is allowed to stay in water for a longer time increasing the availability of vessel for business. It also helps operators with increased flexibility in choosing the dry-docking window with properly planned maintenance programs and schedules.

Guidelines and Requirements for Extended Dry-docking Program

The maximum dry docking period is extended by allowing the qualified ships to undergo In-Water Surveys (IWS) which help to increase the period between two dry-docks. However, it is to note that only those ships which produce satisfactory results in these surveys are allowed to continue with the EDD program.

Each classification society has its own requirements to allow a ship under extended dry-docking period to ensure highest levels of quality and safety. Some of the main requirements for a ship to be allowed under this special program are:

– Presently, the extended dry-docking program is available for only container ships, general cargo ships, and multi-purpose dry cargo vessels. This means that ships such as tanker and passenger vessels and those subjected to Enhanced Survey Program (ESP) and Extended Hull Survey Program (EHSR) cannot opt for extended dry-docking.

In accordance with IMO resolution A744 (18), the scheme cannot be applied to Enhanced Survey Programme vessels – most bulk carriers and tankers – and under the SOLAS Convention it cannot be applied to passenger vessels.

– Ships belonging to all flag states cannot apply for the extended dry-docking program. The flag administration first needs to approve the type of vessel and the owner for the extended dry-docking scheme. A ship can apply for the EDD only if its flag state approves of the program.

– Age of the ship plays a major role during acceptance for the EED program. The ideal age for the commencement of Extended Dry Dock Program is between 0-5 years and less than 10 years. However, older ships can be considered for the program depending on the flag state, ship type, classification society and other design and operational factors.

– Inspection of hull and paint coating is one of the most important factors considered for extended dry-docking. The paint manufacturer provides the criteria for which the coating will be valid for 7.5 years. Several factors such as vessel speed, area of operation, vessel utilization, and idle time are taken into consideration while deciding the validity of the coating. High quality hull coating is an important requirement for extended dry docking.

Image credits: hydrex.be

– Anti-Corrosion system (corrosion protection) is an absolute must for EDD. Ships with high quality underwater coating are only allowed for the extended dry-docking. Moreover, sacrificial anodes attached to the hull must be capable for renewal in water and the impressed current corrosion protection system must be monitored for effectiveness. The ballast tanks must also have good coating condition.

– The quality and thickness of coating requirements are different across EDD providers. For e.g. GL has the following requirements for ships allowed for EDD program:

-> As criteria for the implementation of the “Extended Dry-Docking Interval”, at the time of new building, the corrosion prevention system for the bottom shell has to fulfill the following requirements:

-Dry film thickness of coating for 7.5 years has to be an average of 300 μm

-Anodes (Alu/Zinc) prepared for 7.5 years

Alternatively,

Impressed current system is to be installed and maintained

– >As criteria for the implementation of the “Extended Dry-Docking Interval”, for ships in service, the corrosion prevention system for the bottom shell has to fulfill the following requirements:

-Dry film thickness of coating for 7.5 years has to be an average of 250 μm

-Anodes (Alu/Zinc) prepared for 7.5 years

Alternatively,

If installed, in impressed current system, is to be maintained and documented in the Planned Maintenance Scheme

– The results of the in-water survey play an important role in deciding the next dry-docking schedule for the ship, even if the ship is under Extended Dry Docking Program. If the results of this survey are found unsatisfactory, then the operator is asked to book a dry-dock within one month of the IWS (In water survey).

Summary of Extended Dry-Docking (EED) Scheme

– Dry-docking period extends from 5 to 7.5 years

– Dry-docking is replaced by In-Water Surveys (IWS) from authorized underwater inspection service providers

– Only those ship types and operators approved by Flag administrators are considered for dry-docking survey

– Not all types of ships can apply for EDD

– Generally ships of age not greater than 10 years are considered for EDD

– Special requirements for hull condition and paint coating thickness are required

– Proper ship corrosion protection system is a must

– Results of IWS decides the next dry-docking schedule

-Requirements for a ship to be approved for EDD will vary across EDD service providers

– Special surveys can be assigned to ships if required

– The scheme can be discontinued anytime if the ship doesn’t meet the stated requirements

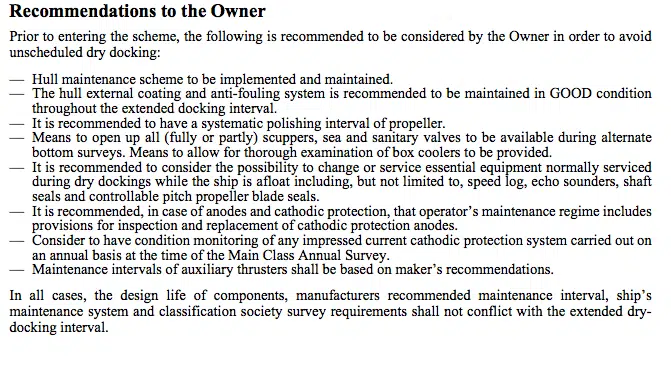

DNV, one of the providers of Extended Dry-Docking, offer special recommendations to the ship owners who plan to opt for EDD for avoiding unscheduled dry-docking.

Image Credits: DNV

Further Reading:

- DNV EDD Notes

- LR EDD Guidance

Extended Dry Docking is an excellent option for ship owners to avoid unscheduled and costly dry-docking, provided a well planned and documented maintenance/survey schedule is implemented.

Disclaimer: The authors’ views expressed in this article do not necessarily reflect the views of Marine Insight. Data and charts, if used, in the article have been sourced from available information and have not been authenticated by any statutory authority. The author and Marine Insight do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendation on any course of action to be followed by the reader.

The article or images cannot be reproduced, copied, shared or used in any form without the permission of the author and Marine Insight.

About Author

Raunek Kantharia is a marine engineer turned maritime writer and entrepreneur. After a brief stint at the sea, he founded Marine Insight in 2010. Apart from managing Marine Insight, he also writes for a number of maritime magazines and websites.

Do you have info to share with us ? Suggest a correction

Latest Shipboard Guidelines Articles You Would Like:

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Hi, I would like to ask, What is the latest trend in dry docking service today?

Hi, Good day/dear I would like to know that how we can develop a Technical check list in order to best selection of Marine Paints Manufacturer for the Dry Docking.