10 Safety Points for Remote Manoeuvring System of Marine Engine

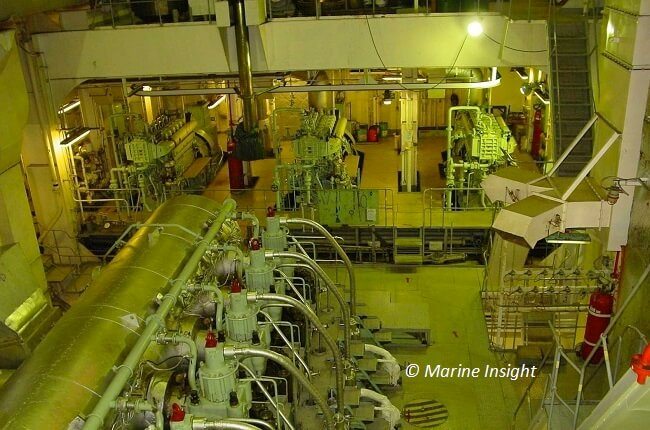

Remote control manoeuvring system helps the ship engineers and deck officers to steer the ship safely from a control station (bridge or engine room), easing the process of monitoring and operation of marine engine power plant.

Considering the importance of this system, it is imperative for marine engineers to understand the know-how of the remote control system provided for maneuvering the main engine.

Every engineer on ship must know basics of pneumatics, electrical and electronic systems, hydraulics, wiring, piping, knowledge of steering etc. and other systems related to manoeuvring of marine engine.

Without doubt, the engine manual is the best source of information for understanding and operating engine room machinery. The manual must be consulted whenever doing any troubleshooting, maintenance or operating the engine for the first time.

Let’s take a look at ten important safety steps that must be taken when operating/ maintenance or handling remote control system to maneuver a ship’s engine:

1. Never touch any machinery part or open any door/ cover when operating remote control components as it is dangerous and can lead to malfunction if mistreated during operation

2. Once the maintenance is performed on the devices, close the door/ put cover on them to avoid entry of dust or foreign material

3. Always check all the remote control operations from maneuvering handle in the engine control room before entering or leaving port

4. If main engine is stopped due to automatic shutdown/ slowdown, first action is to move the maneuvering handle to stop position and then troubleshoot the problem before restarting the engine

5. Before doing maintenance of electrical circuit of remote control system, ensure to switch off the supply. There can be multiple power supply for such system, check and turn off all before opening

6. Before applying megger or withstand voltage test to such circuit, ensure total of all wires to the unit that prohibit megger test in order to safeguard electronic device

7. Ensure to check drawings of electrical circuit before working on it and do the contact cleaning routine as loose contacts and deposits are the most normal causes of malfunction in electrical system of remote control maneuvering

8. If shore power is being connected to the ship in layup or dry dock, ensure to turn off the power supply switches of remote control system as voltage drop during transferring of power supply can damage the remote control system and lead to failure in operation of the same

9. Before doing any maintenance in the pneumatic part of the remote control system, ensure to shut the air supply and drain the air inside the piping system

10. When opening air pipes ensure to replace damage rubber seals and thread tapes while assembling them back. When assembling pipe fitting to a pneumatic device, never apply seal tape or sealant to the pipefitting or to screws to avoid falling of detached parts into the device or piping

The Remote control system has to be the most important system in the main engine and any malfunction of this system during maneuvering or in traffic channels may lead to critical condition like accident, grounding, collision etc. Periodc maintenance of remote control system is of extreme importance and the engineers have to keep a check on the correct operation and spare parts (often ignored) of pneumatic and electrical devices incorporated in the remote control maneuvering system.

Latest Shipboard Guidelines Articles You Would Like:

Do you have info to share with us ? Suggest a correction

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Web Stories

About Author

An ardent sailor and a techie, Anish Wankhede has voyaged on a number of ships as a marine engineer officer. He loves multitasking, networking, and troubleshooting. He is the one behind the unique creativity and aesthetics at Marine Insight.

Above mentioned points are ok, still lot of important points are missing!!!!