Ships Without Skippers: Researchers Believe Unmanned Vessels Are The Future

Researchers at MARINTEK believe that in ten to twenty years time there will be 200 metre cargo vessels plying the oceans without the need of a captain or crew. But before this can happen, we will be seeing the technology working on an existing vessel.

The SINTEF company MARINTEK is one of eight partners working intensely to develop systems which can function without human intervention. Both day and night watches will be taken care of by a control centre onshore, and the Norwegian researchers believe that a 3 to 4 Mbit broadband connection will ensure effective communication between the vessel and the control room.

“There aren’t many willing to believe it, but if the project partners succeed in overcoming the challenges we are currently working with, vessels such as this will in fact be safer than many of those on the high seas today”, says researcher Ørnulf Rødseth. “Human error, solely or in part, is the cause of more than 75 per cent of today’s vessel accidents”, he says.

Lower speeds, less fuel

The basis of the project is that merchant shipping in Europe is suffering from the fact that fewer people are interesting in working at sea. It’s not an attractive job sitting cooped up in a vessel looking out over the empty ocean for 14 days, and with only limited contact with family and friends. At the same time, the volumes of goods being transport are increasing considerably and the freighters must be crewed. There are more than a hundred thousand merchant ships in operation around the world, and some areas, such as the English Channel, are constantly overcrowded.

Unmanned vessels, looking after themselves, may be the answer to the problem of making the maritime industry more attractive and sustainable. Such ships can reduce speeds, for example from 16 to 11 knots, and in doing so save 50 per cent of the fuel they burn today. CO2 and other emissions will be reduced and the shipping industry will make massive savings due to lower fuel consumption. Currently, fuel represents by far the largest share of operational costs. If the industry can also save on salary expenditures, it will accept that journeys may take a week or so longer than they do today.

Status monitoring and on-board satellite communications are key to the work currently being carried out by the Norwegian researchers. Ørnulf Rødseth emphasises that it is not their job to build a new vessel.

“What are you going to do then?”

“Well, the technology for electronic positioning, satellite communications and anti-collision measures already exists”, he says. “Many vessels are also equipped with advanced sensor systems. It is one thing to have the technology, but quite another to bring it all together and demonstrate that it works well enough to satisfy the authorities and the industry”, says Rødseth.

“This is why there is a lot of talk about the costs issue, as well as the concerns of shipowners and the general public. We mustn’t forget that current rules and legislation all assume that there are PEOPLE ON BOARD”, he says.

[the_ad id=’172861′]

In order to change the law, researchers will have to demonstrate that safety is as least as good as on existing vessels. For example, even if a sensor system detects an obstacle, the vessel has to be intelligent enough to process the information in order to avoid a collision. Researchers believe that developments such as this will emerge gradually. For example, there will be a transition phase during which it will be safe for crews to sleep at night with the bridge unmanned.

SINTEF investing 12 million

Even tougher is the requirement that technical equipment on board has to be fully functional for periods of two to three weeks. There will be no-one around to carry out repairs. “This is perhaps our biggest challenge”, says Rødseth thoughtfully.

In order to carry through its tasks, SINTEF has invested NOK 12 million of its own funds in a project it has called Seatonomy. MUNIN is one of four projects with the aim of identifying problems and developing methods and tools to provide safe and cost-effective autonomous systems.

“There is a need for safe, inexpensive and more robust autonomous vessels in many of SINTEF’s research fields, including aquaculture, the offshore wind and subsea sectors, and in connection with oil and gas production and mineral exploitation. Safety is key across all these fields, and the systems developed must be cost-effective”, says Rødseth.

FACTS:

- The EU project MUNIN (Marine Unmanned Navigation through Intelligence in Network) is running from 2012 to 2015.

- The total budget is EUR 3.8 million, of which the EU itself is contributing 2.9 million.

- The objective is to develop and verify an autonomous vessel concept.

- SINTEF’s partners are Chalmers Technical University in Sweden, the Fraunhofer research institute in Germany, University College, Cork in Ireland, Hochschule Wismar University and MarineSoft in Germany, and Marorka in Iceland. The Norwegian partners are MARINTEK and the Trondheim company Aptomar, which are very advanced in their work developing sensors.

- Seatonomy is a SINTEF Group project (2013-2016) looking into the design and development of autonomous, unmanned vessels.

Many players on the bandwagon

The German research institute Fraunhofer is heading the MUNIN project. Sweden is working on research into the control centre, and Germany on the machinery and navigation. Ireland is looking into the legislative aspects.

There are similar projects taking place in many other places. In its futures report, Det Norske Veritas GL considered autonomous vessels to be a realistic prospect in the longer term.

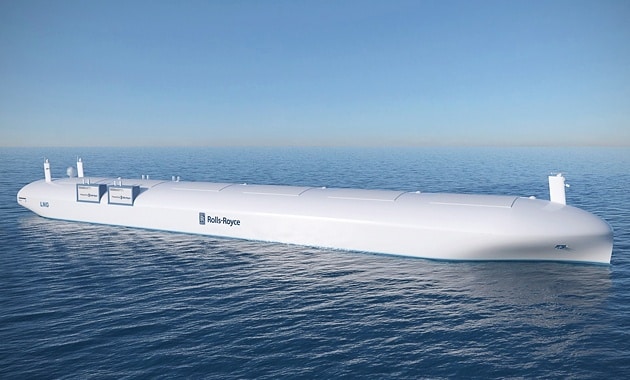

Rolls Royce has published conceptual sketches for its own autonomous vessel design, and Oskar Levander, who heads Rolls Royce’s research activities in this field in Ålesund, believes that a single ‘skipper’ on land will be able to operate ten vessels.

This idea still appears to be on the drawing board, and Ørnulf Rødseth is confident that the MUNIN project has advanced much further in terms of both technology and analytical work.

[the_ad id=’173168′]

From playful ideas to reality

This is the vessel of the future. And you are allowed to toy around with future trends. Rødseth freely admits that many different and peculiar ideas have appeared on his team’s drawing boards. One good example is the use of water jets.

“Large cargo vessels are equipped with a main engine and a reserve engine”, he says. “The latter supplies reserve electricity, and is powerful enough to power a water jet which can be used for propulsion and steering if the main engine fails.

Changing the type of fuel is another idea. The heavy oils used today are tar-like dregs. In order to avoid maintenance, autonomous vessels will probably have to run on lighter, more expensive, fuels.

“Less expensive, liquid natural gas might be the answer here”, says Rødseth. “But this will involve designing the vessels from scratch”.

The research team has to be realistic and design a model which they know is achievable. This means that some of their original ideas have already been discarded. For example, there is nothing to be gained in terms of costs by developing an autonomous system for navigating in and out of port. There will have to be people on board for an hour or two.

Slowly does it

On longer passages, however, autonomous vessels will be on their own.

“This sounds very strange. Aircraft follow pre-defined corridors based on safety considerations. Will these vessels have to do the same?”

“No”, says Rødseth. “The major difference being that aircraft travel at 1000 kilometres per hour. We’re talking about vessels moving slowly across the open ocean meeting very little in the way of traffic”, he says. “Radar will keep an eye on everything going on. The passage will be adapted to the rules requiring that vessels keep to the right.

And the vessels will be carrying cargoes such as maize and other cereals, or mineral ores. We aren’t talking about high-value commodities. Nor do the cargoes represent an environmental hazard if something unforeseen should occur”, says Rødseth.

You may also like to read:

10 Smart Ship Technologies For The Maritime Industry

An Insight into the Automated Guided Vehicle (AGV) Used in the Maritime Industry

About the Author

The article was first published at gemini.no and has been reproduced with the permission of the author.

Do you have info to share with us ? Suggest a correction

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Web Stories

thank you so much for this blog…

Is that possible when the vessel in trafic

I respect a lot technology but I you are in a command center HOW are you going to protect the cargo of an owner 2000 miles away ( in twenty years they will be no captains because they will be no sailors, sailors are raise at sea, then they project cannot be implemented is usseless they need sailors in the control rooms to maneuver the ships in a seaworthy manner that continue to be the key ), . If they don’t answer this all the project is like garbage, If I am an owner I bet for the crews that are 3% of the cost. The risk is too much. A bulk carrier of today has 10 people on board that is a token crew compared with the crews in the past.

Appreciate what Maritime Industry is doing everything for safety. However, according to my point of view you should create a technology so that seafarers on-board have hi-tech equipments and would be much for safer then. Human beings plus technology. No more collisions. You keep the vessel on automated mode, more piracy attack are going to happen and no one would be able to help. Also, they should think about loss of jobs for thousands of seafarers. Human being makes an error machine notifies them about the same and when machine makes an error human being should be there to help. So let’s hope we come with the right conclusion. Cannot survive a robotic world.

This is possible,..but risky!!!a machine needs to be watched,..breakdown maintenance cannot be predicted…a major trouble in engine room,..fire,flooding,failure of machineries…how can a robot repaired itself?!!it needs a human,..a certain person,that knows the job!!!never mind my english grammar…hehehe!!!

The idea of umman ship is good but paratiaclly it’s impossible , we can reduce manpower by new techanaology . Buts its very high risk as mistake of other vessel or technical problem in these modern vessel, like Fire , collision , grounding , machinery failure , pollution . Result in loss hundreds millions dollors. & insurance will not pay any. Shipper will not take risk of his expensive cargo, Owners will not buy such vessel & this idea if unman ship practically fail. Pls don’t wast huge amount in these kind of research .

Agreed that autonomous ships would reduce costs at open sea and with sufficient oversight they can be safer. But the real challenge will come for the 2 hours or so you need crew when entering and leaving a port. It maybe a practical solution to station a temporary crew in European ports. But it is highly unlikely you could find well trained and competent crew to be positioned in various ports across the world outside of europe, usa, canada and australia. So you will either have to re-position trained european(etc) crew or train local crew to perform these tasks in a reliable manner. Establishing a worldwide network of such crew is no cheaper than to just continue having the “sailors” on board.

I’m quite new to all of this, since I’m in my first year of Nautical Sciences, but I feel like there are to many risks involved with the fully automated vessels. First of all: vessels are becoming bigger and bigger (Cosco is currently building a container vessel of 19000 TEU). There is no way, that vessel can dock on it’s own, so you’ll still need sailors. Secondly and more frighteningly: On our school (and I’m sure on many more) we are being drilled to not blindly rely on your electronic systems, what’s the reason we all are trained in navigation on paper charts, despite the existence of ECDIS/GPS/… . Because a computer is an elekrtonic systems and electronic systems can fail. That’s were humans have to take over, so nothing bad can happen and yes most of the accidents may be by human error. But answer me this, your fully automated vessel is on fire, the system takes counter actions, like the activation of sprinkler systems, the release of Co2,… Because of this fire, the electronic systems are down, the ship is not capable anymore of functioning. What happens than? A) the vessel stops the engines, which results in a vessel in the middle of the ocean that is surrendered to the ocean, it can capsize in a storm, run aground, or even have a collision with another vessel. Option B) even more disastrous: it’s incapable to stop the engines and is just going a long its course (or not) not slowing down for anything, and boom next thing you know a 19.000 TEU container ship crashes into a petrochemicals harbor. And there’s probably a way of making sure that these things don’t happen, but in my opinion it will cost a lot of money. And lastly, the crew on board a ship, form the last barrier between disaster and a happy ending. No matter how many back-up systems will be on board, you’ll never have the same last line of defense. Because machines are machines and they fail, so please invest the money in safety, safety for the humans on board, safety for the environment,…

I’m positioned on a state of the art vessel..a modern day rolls royce..we are fully automated, intergrated and very sophisticated.. and you know what..I am consistantly burdened with the task of what we call on ships..rat killn.. fixn bugs..scratchen ya head..when it works fine, its amazing..but when shit hits the fan…I’m the hero that saves the day..not some geek squad at command center.. this will never work…1 or 2 disasters and they’re done.

As a small child, I spent many hours watching Thunderbirds averting disaster after disaster when fully automated trains, aeroplanes, ships and other machines malfunctioned. 🙂

There’s no way this can happen. You talk about moving products like maize and grains. However, you still have oil onboard for fuel, lube, hydraulic, etc. If you have a grounding you still can have environmental impact. Not all hazards appear on radar, sailboats, floating debris. How can someone in a control center identify these hazards without being on the bridge. Mariners are trained for years before becoming officer of a navigational or engineering watch. You become experienced in the nuances of navigation by having your eyes out the window, not in a radar screen. Lastly, the article mentions how you would need to put personnel onboard for coming into port. Pilots, engineers, seaman for line handling. How do you get all these people aboard without having someone to rig a pilot ladder. How are the engineers going to react to an emergency situation when they aren’t familiar with the engine room? How is the pilot going to navigate without having a Master to explain the idiosyncrasies of the ship? Certainly some good can come from the advanced automation systems the researchers come up with but the bottom line is that Mariners are a valued asset, not a necessary evil.

Yes, it is true that 80% of sea accidents are caused by human error. But it is not from the cause of incompetent seafarers onboard, it’s “fatigue” from overwork can cause 100% errors all the time. I agree to the statement of one fellow here who said that machines can’t repair itself during seavoyage or a loss of ecdis is proved to be fatal in unmanned ships. Computers can’t plot charts manually on a piece of paper and pencil onboard.

https://www.ted.com/talks/yuval_noah_harari_what_explains_the_rise_of_humans

Check ou this speech: Computers will take over. There will be Kings but the populous will have nothing to do but “take drugs and play video games”.

…So much negativity! Nobody would like to see something like this? Really? I for one would like to steer this ship and ten others or whatever from some cozy office, maybe scratch my balls (for real this time), and sleep in my not rolling and quiet bed at home. Shit, I didn’t check the weather today.

Fine in theory – biggest problem – hacking. A country like N. Korea with sanctions against it, could break all sanctions by hijacking via hacking. free cargoes

I am sorry but any of this reasearchers was actualy on sea?

Well all i can say is that seafarer life will be finish in 20 or more years.. i am a sea dogs for 20 year as well. if todays unmanned drone can fly how much more in the next 20 years. guys nothing is impossible for this and i sure it will happen.

Please be noted service at sea is referred to experience for a reason.

Nobody can teach a machine what that is.

They claim that 75% of all accidents at sea is human factors, what about all the accidents prevnted by humans at sea, the more todays seaman prevent accidents thus higher % of accidents by humans.

SciFi Concept and such a waste of money!

This will never happens and if this happens will be episodically only for small marine crafts not for such a projects like ULCC GRT 450 000 or large container vessels up to 19000 TEU – just no chance!

Human factor and Homo Sapiens always will have the conn!

Some people newer give up their struggle, even if its proven by someone who know better, that their ide wont work. Take fore “the so called “moon landing project” Yare Birkeland”. IMO has confirmed that “unmanned ship will not be accepted in international waters”. Above project is intended on a voyage from Prsgrunn to Larvik (a partly international voyage). Captain`s around the whole world, have spoken and issued death row. The project leaders claim that “this will be the first ever fully electric ship, with cero emission and it will remove 40 000 diesel powered truckload from the road” The government is simultaneously building double electric train ( cero emission) track between the same cities. Computer and other manufacturers involved has given up their struggle. So called experts (with no sea experience) have made algorithm to be used to control the unmanned ship, instead of having a seaman on the bridge. Algorithm that are “full of human errors” and “misunderstandings” about the realities. They haven’t got the slightest clue in how it is to be on the bridge on a ship in heavy rain, hail, snow, lightning that will interfere on all electronic signal, including radar, ARPA, GPS, AIS and other positioning equipment. I keep asking my self, who will be stupid enough to issue insurance assertion for above, and be accountable for their error, and who will make sure that the traffic control, is capable to tackle this.

i dont think its a good idea 1. you are taking away jobs that people could have thus adding to the unemployed rate it seems like you are trying to fix and issue by creating another issue.

2. slow speeds… what! are we back in the old days, slow speeds means cargo is gonna take longer to get to the destination and that means the consumer has to wait longer, if i were a consumer id be avoiding buying stuff that needed to be shipped as i dont want to wait longer and longer for stuff, we are in a fast modern world and to go slow is sort of something that would be done in the past.

3. piracy, you become more advanced with autonomous tech so will the pirates, pirates arent stupid people from the 1800’s or so they are people of today that can adapt to changes.

Over 12 years employeed as maritime Engineer, working as Chief Engineer now, and i dare to say that all of it is just a beautifull dream. Like my colleagues said, it is impossible, unless all The vessels around the world will be fully upgraded or replaced în The same Time… One Day down Time în maritime shipping industry and world collapses. As for Straits like Malaca, what is the sollution? Ban all The fishing vessels from the area? Let s see a so called AI, what decisions will take when navigating through 100 fishing vessels. Engine side with all the maintenance, watch, unexpected breakdowns, and so on. Since the worldwide overall quality of the vessels and the equipmnts has been reduced to minimum to minimize expenses… One fully automated ship’s cost will be equal to an entire fleet’s worth. Let s be damn serios, Nobody will pay that kind of Money, it is simply not worthed.

First, MARINTEK changed name to SINTEF Ocean in 2017:-)

I agree that it is very challenging to fully replace human decision making and for now we are mostly looking at using a remote control centre with experienced operators taking care of the complex situations. Alternatives will require some changes in how ship traffic is controlled and/or in COLREG. Traffic separation schemes and more active VTS (in ports/port approach) are possible approaches.

Also, one main argument for uncrewed ships is to scale ship sizes down and use several smaller vessels instead of one big to increase service frequency and flexibility. Currently, this is mostly relevant for certain short sea and inland waterway routes. However, this may also apply to larger ships. There are arguments that the current mega-container carriers is a bad idea from a logistics perspective. The ports become too large, problems with hinterland transport, expensive cargo handling etc. However, this will require significant changes in business models and is not something we are actively investigating now.

@Ornulf: Thank you for the comment 👍

If you guys want to improve the maritime industry, please get rid of all unnecessary paperwork onboard. Then put the robotic ship at sea. Savvy…