Real Life Incident: Ship’s Sea Suctions Choked With Fish

An oil tanker was discharging at an Asian oil terminal. Simultaneously, the vessel was being inspected by a vetting inspector and the owner’s superintendent was also attending. The inert gas (IG) plant was in operation. About four hours into the discharge, the chief engineer (C/E) was informed that the seawater low pressure alarm had been activated. He came to the engine room and observed that all the sea water pumps were showing inadequate discharge pressure. At the time, the high sea suction was in use, and even though it was well under water, the C/E instructed the duty engineer to change over to the low sea suction in order to improve the head.

Immediately, the pump suction and discharge pressures became normal. After monitoring the system for some time, the C/E left for his cabin. After a few more hours, the problem recurred and the C/E again returned to find all seawater pumps had developed vacuum condition on the suction side and were showing very low discharge pressures. It was immediately suspected that the strainers inside the sea suction chests were clogged. However, with the cargo pumps and IG plant operating at full capacity, it was decided to use both the high and low sea suctions together to avoid stoppage of any of the seawater pumps. It was not possible to open up any of the sea chests to clean the strainer without halting the discharge, with attendant commercial implications.

The Master and superintendent were informed of the serious situation, when, by chance, the terminal announced a temporary stop in cargo operation. Until this stoppage time, the engine room had spent a nervous few hours with the pumps struggling to develop adequate water flow. In the middle of this crisis, a class surveyor was scheduled to attend for annual survey. On arrival, he declared his intention of testing the operation of the deck foam monitor with both fire and service pumps, which was quite a tough task under the circumstances.

With great trepidation, the engineers were able to adjust the pump suction and discharge valves to satisfactorily demonstrate the operation of the deck foam monitor. Soon after the departure of the class surveyor, cargo operations were halted at the terminal’s request and with the IG scrubber and condenser sea water pumps stopped, and auxiliaries under control, the low sea chest was opened up for inspection.

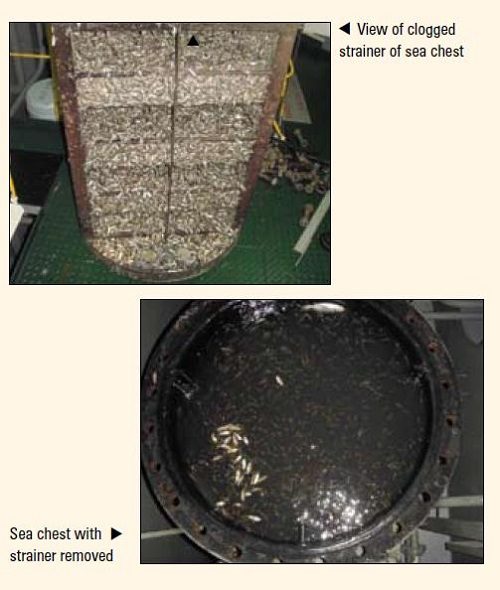

A mass of tiny fish was found inside, and when the strainer was extracted, it was found to be completely choked from the suction side. After non-stop work by the crew, the suction was completely cleaned out, and the strainer replaced after the mesh was cleared. After the sea chest was boxed up, it was put in use and all seawater pumps were tested and found to be developing normal pressures. The high sea suction was also found to be choked with fish, and was similarly cleared and boxed up, by which time cargo discharge was resumed, with terminal instructions for continuous discharge until completion. Unfortunately, just four hours after resuming cargo discharge, seawater pressure again became low, forcing the simultaneous use of both sea suctions.

The Master and superintendent were regularly updated of the situation, when, without prior intimation, port state inspectors boarded the ship. The mess near the sea suctions was quickly cleaned up, and the vessel passed the inspection creditably despite the accumulated stress of the past 24 hours. Just after the port state inspection, and towards the end of cargo discharge, abnormally high temperatures were observed in the steam condenser shell and condensate lines, calling for urgent corrective actions. Discharging was finally completed later that night. An exhausted engine room crew once again opened, cleaned and boxed up the sea suctions (again filled with tiny fish) and the ship sailed from the terminal without any delay, much to everyone’s relief.

Corrective / preventative actions

1. The fleet (especially a sister vessel) was advised to use high sea chest in ports as this is generally located close to several overboard discharges; e.g. ballast, condenser sea water, fire and general service (GS), and IG scrubber pumps. The turbulence created in the vicinity of these overboard discharges may help prevent fish being drawn towards the high sea suction.

2. It was also suggested that regular injection of steam into sea chests might assist in keeping the strainers clear of unwanted fishes and other organisms.

Reference & Image Credits: nautinst

Do you have info to share with us ? Suggest a correction

- Real Life Incident: Vessel Collision in Good Visibility

- Real Life Incident: Severe Injury To Deck Crew While Leaving Berth

- Real Life Incident: Departure Damage in Very Restricted Waterway

- Real Life Incident: Low Situational Awareness Has High Impact Consequence

- Real Life Incident: Fouled Anchor in a Designated Anchorage

- Real Life Incident: Fire On Barge Carrying Scrap Metal Causes $7 Million Worth Of Damage

Latest Case studies Articles You Would Like:

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.