Real Life Accident: Ship’s Bosun Dies Due To Fatigue And Dangerous Conditions

While underway but not yet in open sea, the bosun was instructed to properly secure the port lifeboat for sea. He called on a seaman to help him with the work. By the time the seaman arrived at the lifeboat station the bosun had already begun the task. The bosun was sitting astride the forward davit cradle, close to the underside of the lifeboat, trying to secure the forward trigger line to the trigger mechanism on the cradle (see photo).

The seaman climbed the aft cradle ladder and attempted to do the same with the aft trigger line. When the seaman realised there was not enough slack in the line to permit the connection, he descended the ladder with the intention of lengthening the turnbuckle at the other end. Shortly after reaching the deck he heard a noise; he then saw the lifeboat sliding down the cradle of the roller gravity davits.

The noise also alerted the ship’s electrician who was nearby. Both the electrician and the seaman rushed to the lifeboat davit winch and applied the brake. The lifeboat stopped descending but not before hitting the bosun, sending him backwards. He clung to the trigger line momentarily, but lost his grip and fell overboard into the water 15 metres below.

‘Man overboard’ was quickly communicated to the bridge where the OOW, a helmsman and a pilot were navigating the vessel. The pilot immediately put the engine to dead slow ahead, but the confined area of the channel prevented a turning or full astern manoeuvre. The pilot also released the port smoke buoy, but this fell into the partially deployed port lifeboat. The Master arrived on the bridge and released the starboard smoke buoy. Another life ring was also thrown into the water, and persons on deck could see the bosun apparently swimming some 20 metres from one of the buoys; however, they lost sight of him within minutes. Five days later, the bosun’s body was recovered approximately 10 miles from the site of the accident.

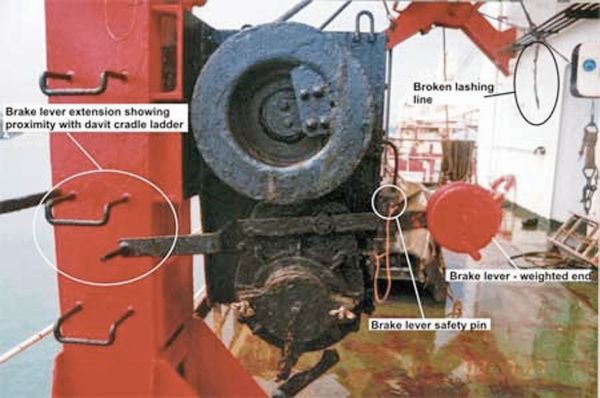

It was observed during the course of the investigation that the outboard end of the brake lever (opposite the weighted end) was extended such that the handle was near the vessel’s side to enable the person who controlled the brake, by pushing down, to view the lowering of the lifeboat. The handle was in very close proximity to the second rung of the aft cradle ladder (6 cm below and 5 cm away, see photo below).

Although a manufacturer’s instruction manual for the davit and its equipment was found on board, the lowering and hoisting instructions were of a general nature. They did not include specific safe working practices or details on the harbour pin and trigger line arrangements.

During the course of the investigation it was also discovered that the bosun had participated in various operations prior to the accident, so that during the previous 24-hour period he had been off duty for only about four hours. Other facts collected during the investigation showed that the vessel was operating with fewer deck ratings than specified in the Minimum Safe Manning (MSM) Certificate. This possibly contributed to the bosun’s fatigue, as the same amount of deck work had to be

performed with fewer persons.

Investigation findings

- The 12 mm gap between the safety pin and its brake release lever, and the less-than-adequate maintenance on the brake-lever mechanism, contributed to the unexpected release of the lifeboat down the davit cradle.

- The wire rope used as the lashing line was in a severe state of corrosion and well beyond a serviceable state.

- The davit cradle ladder rungs were located in very close proximity to the faulty winch brake lever, and as the seaman descended the aft davit cradle, he probably stepped on the winch brake lever extension, instead of the ladder rung, and released the lifeboat.

- The ladder rungs only provided vertical access at the extreme outboard end of the davit cradle, compelling personnel to place themselves in a dangerous position on the inclined portion of the davit roller track when securing the lifeboat.

- With the davit winch brake disengaged, the corroded lashing line failed to hold the weight of the port gravity davits and the suspended lifeboat, allowing the assembly to slide down the davit cradle, knocking the bosun overboard.cradle.

- The vessel was operating with fewer than the minimum number of deck ratings required by the MSM certificate. Additionally, the practice of assigning ratings to duties other than those described in the MSM certificate undermines the criteria under which the MSM was issued.

- In the 24 hours preceding the accident, the bosun only had four hours off duty; his judgment, reaction time and alertness would have been adversely affected by fatigue.

Do you have info to share with us ? Suggest a correction

- Real Life Incident: Vessel Collision in Good Visibility

- Real Life Incident: Severe Injury To Deck Crew While Leaving Berth

- Real Life Incident: Departure Damage in Very Restricted Waterway

- Real Life Incident: Low Situational Awareness Has High Impact Consequence

- Real Life Incident: Fouled Anchor in a Designated Anchorage

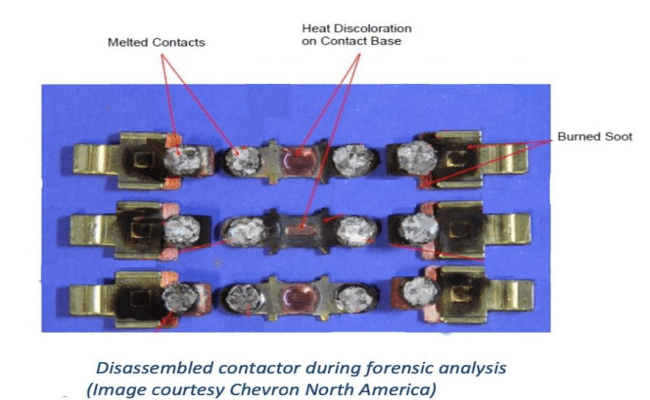

- Real Life Incident: Fire On Barge Carrying Scrap Metal Causes $7 Million Worth Of Damage

Latest Case studies Articles You Would Like:

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Web Stories

Number 8 should have been the absence of a specific instruction manual, complete with specific diagrams and pictures. Many times in my career I was in the position of trying to figure out how to properly understand and safely operate a piece of equipment with generic instruction manuals after way too much effort learning something that should have been perfectly straightforward. Often they would be translations of translations of the original manufacturer’s native language. Typically, I would try to leave step by step ‘instructions for dummies’ in my relief notes so my relief wouldn’t have to go through the same waste of time.