10 Precautions to Take Before Operating Controllable Pitch Propeller (CPP) on Ships

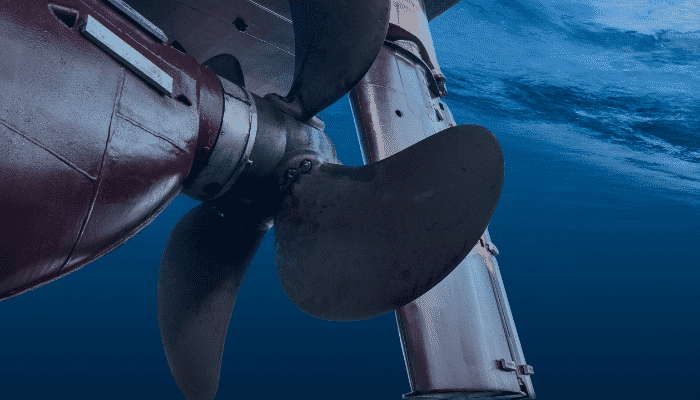

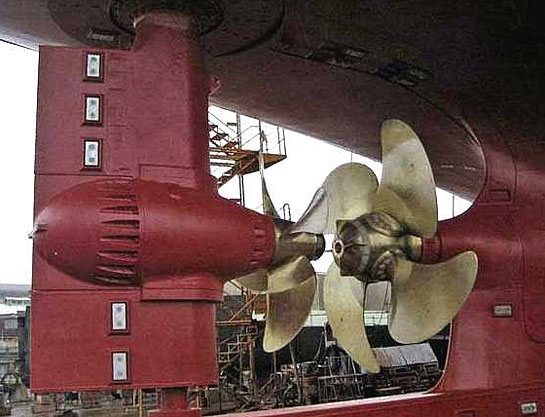

The driving force of a ship comes from the rotation of propeller(s), which is attached to the main engine of the ship. The two main types of propellers that are used in merchant vessels are:

- Fixed Pitch Propeller (FPP)

- Controllable or Variable Pitch Propeller (CPP)

As the name suggest, in fixed pitch propeller, the blades are fixed with the propeller boss and hence their pitch cannot be changed. However, in Controllable or Variable Pitch Propeller (CPP), the propeller blades are attached to the boss and their pitch can be altered via the hydraulic system.

Both the types of propeller systems have their own advantages and disadvantages.

In Controllable Pitch Propeller (CPP), the main engine can be started with blade pitch set to 0. This decreases the fuel consumption and also reduces the load on various engine bearings and its shafting during the starting procedure.

If you are working on a ship with a Controllable Pitch Propeller (CPP) drive, do ensure to take the below mentioned precautions before operating it:

1. Operation from Remote Position: Operate the CPP from Remote control position for ahead, astern and stop position and check the pitch position indicator located near the stern shaft.

2. Operation from Emergency Position: Operate the CPP from Emergency control position which is located near the stern shaft for ahead, astern and stop position and check the pitch position indicator.

3. Check for Leakages: Ensure their is no oil leakage from the system. Even a small leakage can lead to failure of the system at later stage of operation.

4. Maintain the oil level: Check and maintain the oil level in the hydraulic tank of the system at all times. Also, ensure that all the alarms in the tanks are in working condition.

5. Check the pressure: Ensure their is no loss of pressure once the desired angle of pitch is achieved.

6. Start The Engine At Zero Pitch Angle: Always start the main engine at zero pitch angle as their will be a zero propeller resistance during the start, leading to less load on the shaft bearings.

7. Check all the Parameters: Check all the parameters of the main engine are within limits and check the temperature of all bearings including the shaft bearings.

8. Carry out Hydraulic Oil Analysis: Analysis of hydraulic oil used in the Controllable Pitch Propeller (CPP) system to be carried out onboard to check the condition and water intrusion.

9. Run Engine At Constant Speed: If shaft generator is fitted with power Take off/ Gear constant ratio for power production, the engine with CPP should be run at constant speed even at reduced load. This will ensure the efficiency of Controllable Pitch Propeller (CPP) and engine is maintained.

10. Perform Frequent Overboard Checks: Frequent overboard checks near the stern area to be performed during starting of the Controllable Pitch Propeller (CPP) for oil leakage from the sealing ring.

Controllable or Variable Pitch Propeller (CPP) eases the use of other fuel efficient machinery such as shaft generator and also reduces load on the ship’s engine. It is a complex and expensive installation as compared to the Fixed Pitch Propeller (FPP) and hence engineer officers onboard must be skilled enough to ensure no breakdown takes place by knowing the system inside-out.

Over to you..

Do you know any important points on Controllable Pitch Propeller (CPP) that can be added to the above list?

Let’s know in the comments below.

Do you have info to share with us ? Suggest a correction

About Author

An ardent sailor and a techie, Anish Wankhede has voyaged on a number of ships as a marine engineer officer. He loves multitasking, networking, and troubleshooting. He is the one behind the unique creativity and aesthetics at Marine Insight.

Latest Marine Technology Articles You Would Like:

- 10 Harmful Effects Of Impure Air On Ship’s Machinery

- 10 Important Things to Check While Starting Fuel Oil Purifier on Ships

- 10 Noteworthy LNG-Powered Vessels

- 10 Points for Efficient Turbocharger Operation On Ships

- 10 Practical Tips to Handle Engine Room Pumps

- 10 Precautions to Take Before Operating Controllable Pitch Propeller (CPP) on Ships

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

A person without the operational knowledge of the system, shouldn’t be allowed to handle it.

Overaull every 10 years the hydraulic e blades arrangement

I’m been working a lot with CPP vessel at the offshore oil field worldwide and it’s always successful have not complein at all Thanks. Best Regard C/E.Eng Oscar Acosta

For apprentices and and other people who don’t have any experience with cpp system is a good article. This kind of guidelines are not needed to people who know how to do their job

DEAR SIR

THE INTER ACTION BETWEEN HULL AND PROPELLER MAKE VEBEATION

FPP Economical in all parts design

without on case the manoeuvring.

CPP very good in small uint sizes with big hours power as tugboat.

IN FPP ON SLOVE PROBLEM TO REDUSE VIBRATION I HAVE AND ALSO CPP.

BEST REGARDS

MARINE ENGINEER SURVEYOR

AHMED ABDALLAH

Great guide

ensure that the 0 indicator position is effectively the zero pitch position. This needs to be verified regularly at the OD box. I was on a ship once during my first command where the zero pitch was effectively at a marginally astern position on the combinator. In other words, if the combinator was kept at 0 position, the vessel will still have marginal headway. This can be dangerous at times.

Sir what is CPP working pressure, hydraulic/oil/air?