How to Charge Refrigeration Plant on Ships?

The main use of refrigeration plants on ships is to keep cargo and food provisions at low temperature to prevent them from spoiling. The reefer plant is a combination of various machines such as compressor, valves, heat exchangers etc., which are connected to each other through pipes and joints.

While in operation, the refrigerant used in the refer plant gets consumed or is reduced in quantity because of leakage in the system. Reduction in quantity of refrigerant may lead to troubles in the plant such as-

- Short Cycling of Compressor

- Too low suction pressure

- Difficult to maintain temperature of rooms and holds

- Reduction in the efficiency of the plant

When the above mentioned problems occur, it indicates that the plant has to be charged with the refrigerant.

There are two methods for charging reefer plants: Liquid charging and Gas charging.

Now a day’s gas charging is preferred over liquid charging because it is more safe and simple.

Gas Charging of Refrigeration Plant:

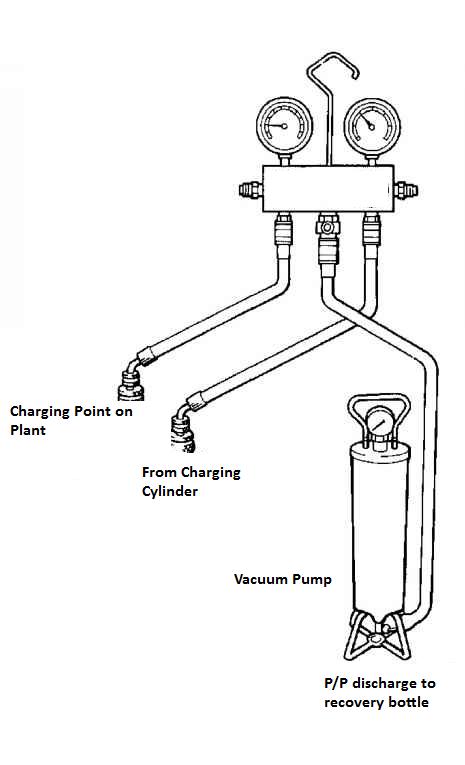

For gas charging, a special T piece valve block with mounted pressure gauge is provided to combine three connectors inter-connecting:

-Vacuum pump

-Charging Cylinder

-Charging Point

Following steps are to be taken for charging gas into the reefer plant:

1. Connect gas bottle or charging cylinder, vacuum pump and charging point in the reefer system to the valve block.

2. The discharge of the vacuum pump is to be connected in the empty recovery bottle

3. First open the valve between vacuum pump and charging bottle located in the valve block without opening the main valve of the charging cylinder. This will remove all the air inside the pipe. Once vacuum is reached, close the valve of charge cylinder in the valve block

4. Now open the valve of the charging point pipe in the valve block and run the vacuum pump until the vacuum is reached. This will remove the trapped air from this pipe. Then shut the valve in the valve block

5. Now keep the system idle for 5 minutes to check there is no pressure drop. This will ensure there are no leakages in the system

6. Now open charging bottle pipe valve and the charging point pipe valve located in the valve block. This will set the line for charging. Ensure that the vacuum pump valve is shut

7. Now open the main valves in the charging cylinder and charging point of the reefer system

8. Do not overfill the system. Make sure the receiver has 5 % space for expansion

Ensure that no refrigerant is leaked out in the environment as these effects the ozone layer in the atmosphere.

Note* :Gas bottle is kept on weighing scale for measuring the amount of charged supplied to the system.

Image Credits:

justinconover, wn

Do you have info to share with us ? Suggest a correction

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

in gas charging in refer plant…

after creating vaccum in both the pipe lines of charge air cyl and charge pipe connection, HOW GAS FLOW WILL OCCUR? as there is equal pressure in both the lines?

How do you remove excess charge in a reefer plant?

And what are those extra connections found on the sides of the charging block?

@ Datta:

The Charging bottle is a pressurized gas bottle hence gas easily flows from the pipes

If the plant is excessively charged, then you have to stop the system, collect the gas and remove it in to the collecting bottle.

how does one come to knopw during charging that the amount charged is adequate for the system?

As Stated, gas bottle is kept on weighing scale. The amount of gas charged is noted with weighing scale and receiver’s sight glass.

May i add :

Point 9 – Open condenser outlet valve.

Point 10 – Slowly open the compressor suction valve. Once the compressor is running, open it fully.

Point 11 – Once the system has settled down, check the liquid line sight glass for bubbles and check individual room temperatures.

How to remove air from the refrigerent system

FYI – Liquid charging of refrigeration systems is preferred through filter/dryer.

When we r collecting gas in receives compressor initially stops in lp cut out then we’l close the suction and discharge values of compressor,when we open charging valve in lp side,compressor starts again and we’l open discharge and suction valves slowly and receiver collects the gas…is this the procedure?..or without compressor running we can charge the gas?

Also can u discuss oil charging and removing methods. How is it done

Thanks in advance

Is it necessary to close suction and discharge valves of the compressor during vacuuming the system?

And, why is it that once we have charge the system, run the compressor, the high pressure cut outs but the temp still high. (all valves are open)

There is a charging port at the liquid receiver, is it ok to charge there after vacuuming the system?

Thanks you so much for this site.

@Jonathan Closing of suction and discharge valve is not necessary.

When the system is recharged, the compressor has to do additional work on the fresh refrigerant vapors to pump them in the system. hence its temperature is higher than normal.

Yes. System can be charged after performing vacuum test

Why are u need vacuming system.i am also direct connect refrigent cylinder.

Sight glas in reefer compressor is very low.how to recharge it using only a manual pump,

You lightly skipped over the fact that most blended gases now used at sea and soon totally used need to be charged as liquid. If they are charged as gas they will simply defragment into constituent parts and NOT WORK!

why you need to shake the bottle or turn it upside down, when you charging refrigerator plant?

which is the best place of charging ( compressor, condenser, drier, oil separator)

I replaced my bad 10hp to another one and recharge again but my reefer didn’t go to -20 degree again, what can I do to that

I change the bad compressor of my reeser to another one and recharge it with 134a gas but it didn’t go to -20 degree which is the set temperature again what can I do to that

We have created online forums for such technical discussions. Please visit: https://forums.marineinsight.com

How once know the vaccume process is completed

With the reading of the vacuum gauge.

How do you know one kg gas charged to reefer

How can he know one kg gas to charge in system