What Is A Floating Storage Regasification Unit (FSRU)?

A Floating Storage Regasification Unit (FSRU) is a vital component required while transiting and transferring Liquefied Natural Gas (LNG) through the oceanic channels. Therefore, FSRU can be termed as a special type of ship used for LNG transfer.

As viable and exceedingly environment-friendly LNG is as a fuel component, the fact remains that transporting the same isn’t that easy. Any slight callousness could result in loss of precious lives and precious fuel, not to mention the further degradation of the oceanic eco-system.

The LNG fuel transported in a semi-cooled slushy state of -160 ͦ, to the required destination, needs to be heated up to its original gaseous state. This reheating needs to be carried out before the gas is pumped into its storage systems. The whole process of freezing and then re-heating the fuel is extremely expensive not to mention time-consuming as well. The resultant solution to this time-consuming process is a floating storage unit with a reliquefaction plant.

Related Reading: Understanding Design Of Liquefied Gas Carrier

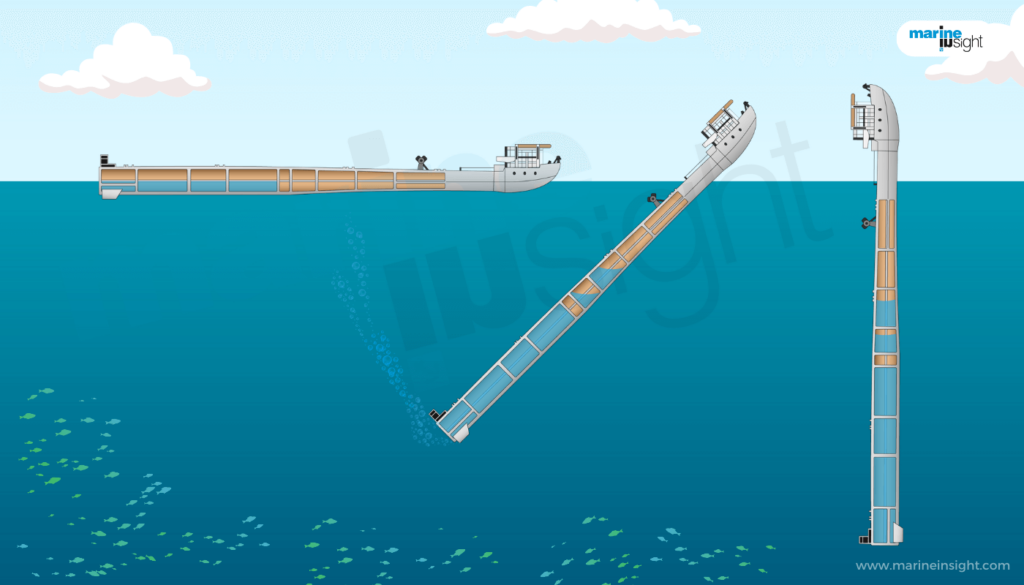

FSRU vessels can be classified either as ships or offshore installations depending upon the design they incorporate. Floating Storage Regasification Unit (FSRUs) can be equipped in two ways:

- either they can be installed as a separate unit aboard the LNG carrier itself or,

- an old gas carrier can be converted into an independent unit and placed in a particular destination as an offshore installation

When the FSRU unit is installed in the ship itself, the construction of the vessel is similar to other LNG ships undergoing LNG trading operation with regular dry docking and complying to all the required international marine safety standards. The major advantage of such installation is that the heating and liquefaction process can be carried out within the vessel itself without having to unload the fuel in its semi-frozen slushy state.

Related Reading: Dry Dock Combo Packs

For the 2nd method, an old LNG tanker is modified with offshore installations as floating LNG unit, which can be either with the propulsion unit (mobile) or without the propulsion unit (fixed offshore unit). The former gives the flexibility to operate the unit as a floating storage unit and as an LNG tanker when required.

In case of the former, the process can be carried out within the vessel itself without having to unload the fuel in its semi-frozen slushy state.

The latter option, however, promises to be more viable as docking a refurbished regasification unit would ensure that the supply and demand chains are adequately balanced.

Since the refurbished Floating Storage Regasification Unit (FSRU) would also be able to provide storing feasibilities of LNG, constant transference of the LNG cargo from LNG vessels would ensure that there is no storage depletion whatsoever.

Generally, such kinds of Floating Storage Regasification Unit or FSRUs ae found near the harbour to prevent time-consumption. But while utilising a refurbished gas carrier as a Floating Storage Regasification Unit, care needs to be taken to suitably positioning these refurbished vessels to prevent any emergency arising near a particular port or harbour.

FSRU consist of following essential equipment:

- Tanks: The first important component of FSRU is the “S” denoting storage of the LNG fuel. This is done by use of either membrane or spherical Moss type tanks. Out of the two, the membrane tank provides better storage capacity for a ship of the same size.

Related Reading: Properties of Membrane Tanks For Transportation of LNG Cargo

- Regasification unit: The next important component of a Floating Storage Regasification Unit or FSRU is the “R” denoting regasification capacity. This is for converting the liquefied natural gas (LNG), which is transported at −162 °C (−260 °F) temperature, back to natural gas at atmospheric temperature.

- LNG Unloading Arms or Hoses: The supply tanker bringing the LNG cargo transfer the cargo from using either an unloading arm fixed in the FSRU or by the use of cryogenic hoses.

Advantages of hoses over arms:

- Easy to install and store

- Takes Less space and cheaper than Unloading arm

Advantages of arms over hoses:

- Quicker offloading

- Ease of operation

- Generates less boil of gas than hoses

- Heating Medium: To vaporise the LNG, Seawater is generally used as a heat source for warming LNG in primary receiving terminals, except for those built in cold areas. This system is known as an open loop system. Strict environmental regulations must be followed for the cold seawater discharged after the heat exchange with LNG.

The other method to heat the LNG from its cryogenic state is closed loop system in which freshwater/glycol mixture is circulated, which is pre-heated by steam from the ship’s boilers.

One more option is to use an intermediate fluid vaporisation process (IFV) in two stages. The first stage uses propane vapour to condense the LNG, and in the second, it is cooled down using a heating medium (e.g. seawater). It can be a mix of open and closed loop system.

The most significant advantages of IFV are

- Less risk of freezing by not contacting the LNG with sea water

- Reduced weight and size of the heat exchanger

Related Reading: Heat Exchangers On Ships Explained

Boil-Off-Gas (BOG) Management: During the LNG loading operation, an excess BOG is generated in the Floating Storage Regasification Unit or FSRU piping in just the same way as it happens when filling onshore tanks. While some of the gas is returned to the supply tanker to fill the space previously occupied by the LNG, the excess gas needs to be managed to avoid overpressurisation of the tanks. A boil-off gas management system will reliquify the boiling gas and transfer it back to the tank using loading or spray lines.

Related Reading: What is Boiling Liquid Expanding Vapour Explosion On Gas Carrier Ships?

Gas Export Arms or Hoses: In most of the inshore FSRUs, the gas is exported via a high-pressure gas export arm. Instead of an arm, they can also be provided with hoses for this job.

The offshore industry has seen rapid growth in FSRUs in recent times, and it is mainly due to the advantages of cost saving and financial flexibility it provides to the owner in addition to the relocation option which is absent in land-based units. The FSRUs provides an excellent opportunity to expand the already growing LNG market internationally.

Disclaimer: The authors’ views expressed in this article do not necessarily reflect the views of Marine Insight. Data and charts, if used, in the article have been sourced from available information and have not been authenticated by any statutory authority. The author and Marine Insight do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendation on any course of action to be followed by the reader.

The article or images cannot be reproduced, copied, shared or used in any form without the permission of the author and Marine Insight.

Latest Type Of Ships Articles You Would Like:

Do you have info to share with us ? Suggest a correction

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Web Stories

About Author

An ardent sailor and a techie, Anish Wankhede has voyaged on a number of ships as a marine engineer officer. He loves multitasking, networking, and troubleshooting. He is the one behind the unique creativity and aesthetics at Marine Insight.

which companies can supply+

floating storage and regasification unit (FSRU)

what is the cost of FSRU? Which countries manufacture FSRUs?

@Pushpanie: New build cost may vary from $240-300m

most of the shipyards are capable to build one.

Many thank for your information about FSRU. I need information about installation of FSRU, about conponen of FSRU.

Currently, How many numbers of Floating Storage & Regasification Units are using in across the world?

Are there any limitations about operating safety for FSRU?