A Comprehensive Guide To Wall Wash Test (WWT) On Chemical Tankers

What is Wall Wash Test (WWT)? All non-chemical tanker folks must be wondering. You may have encountered this term at least once during your exam or sea time, but you’re still unsure about it. Don’t worry; even if you’re a beginner or looking to join a chemical tanker for the first time, we’ve got you covered in this article.

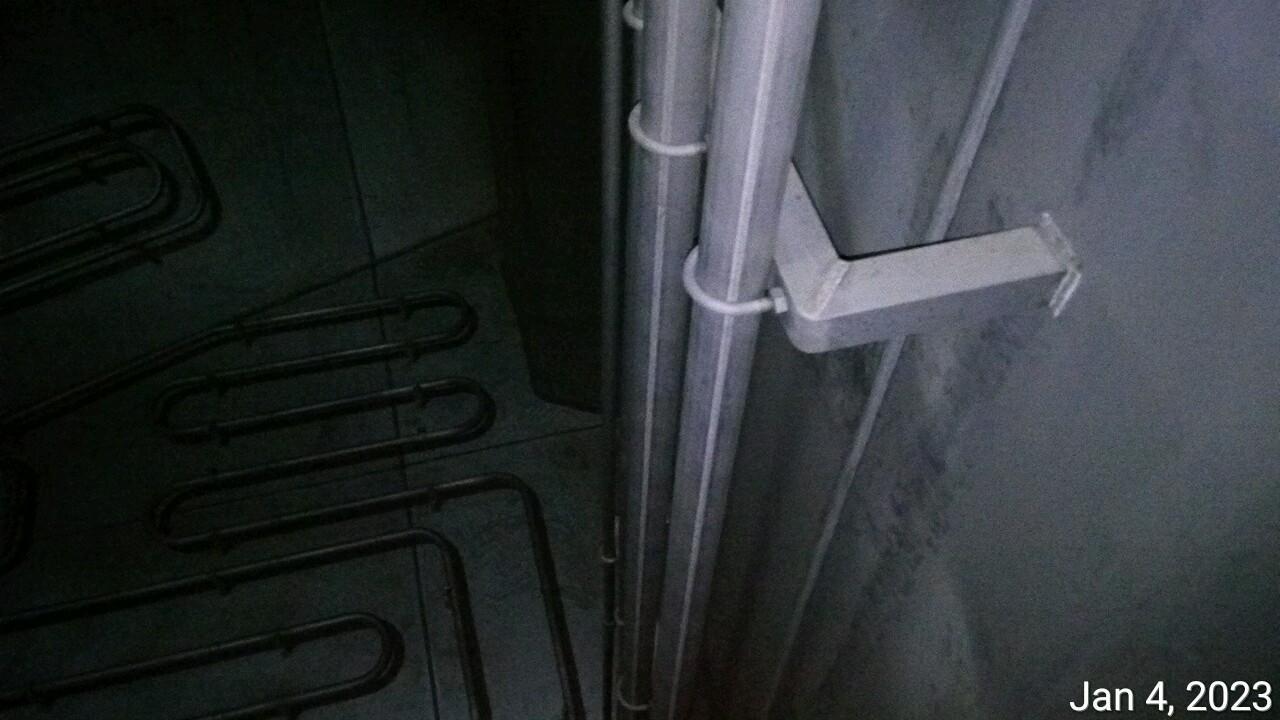

The Wall Wash Test (WWT) is performed on chemical tankers after completing the tank cleaning operation of cargo tanks.

Wall Wash Test (WWT) is required to determine the vessel’s cleanliness, which means whether the vessel is ready or not to load the next cargo and if further cleaning is required or not.

The Wall Wash Test (WWT) requires ship staff to enter the cargo tanks and collect samples from various locations.

An instrument called a spectrometer (UV Test apparatus) is generally provided on board by the vessel charterers or owners to perform the Wall Wash Test (WWT).

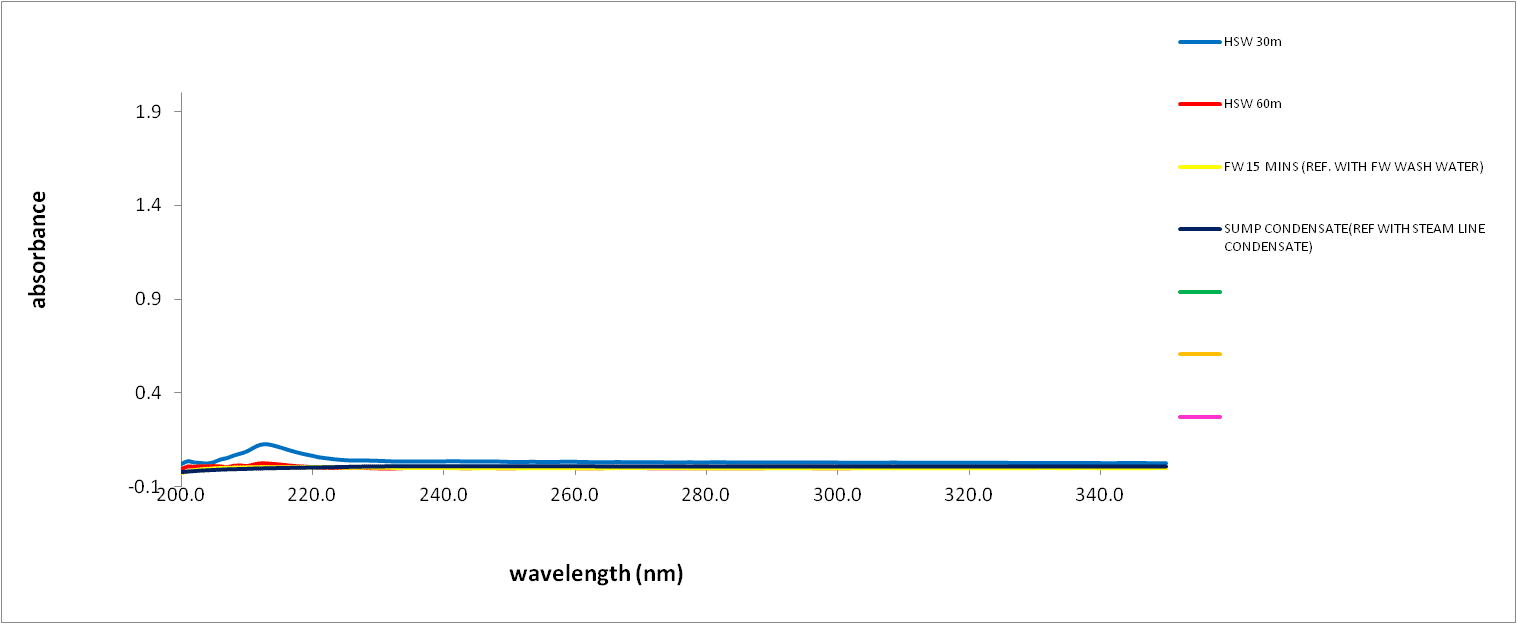

A spectrometer provides result data and UV scan graphs of Hydrocarbon (HC), Chloride (Cl), Permanganate Time Test (PTT), APHA colours, etc., which play a deciding role in determining whether the tanks are suitable for loading the next cargo or not.

Ship staff must familiarise themselves with the use of spectrometers on board to perform the Wall Wash Test (WWT) on board and to ensure compliance with the required cleanliness standards. The charterers may request the result data and UV scan graphs of the Wall Wash Test (WWT) at any time.

Once the vessel reaches the loading port, a cargo surveyor comes on board to take the wall-wash samples. Samples taken by the surveyor will be inspected at a shore-based laboratory. The cargo loading will commence only after the samples taken by the surveyor are passed.

Now for a better understanding of the Wall Wash Test (WWT), we will discuss the following:

- Cargo Tank Cleanliness Standards for Chemical Tankers Tank Cleaning

- Items/Equipment required for Wall Wash Test (WWT)

- Procedures and Types of Wall Wash Test (WWT)

- Wall Wash Test (WWT) vs Wash Water Analysis

1. Cargo Tank Cleanliness Standards for Chemical Tankers Tank Cleaning

The Cargo Tank Cleanliness Standards for Chemical Tankers are defined in the INTERTANKO publication. These standards were developed to simplify the tank cleanliness verification process and reduce the need for in-tank inspections.

The primary purpose of these cleanliness standards is to provide predictability in terms of cost and time required for tank cleaning. Additionally, they aim to avoid tanks over-cleaning, improve port turnaround, clarify charter-party terms, and reduce the number of in-tank inspections in ports.

Cargo tank cleanliness standards are divided into four standards:

- Visually Clean Standard

- Water White Standard

- High-Purity Standard

- Ultra-High Purity Standard

Visually Clean Standard

In the Visually Clean Standard, tanks are inspected from the deck level, and no Wall Wash Test (WWT) is required. Tanks must be clean, dry, and visually free of previous cargo residues and foreign matter. There should be no uncharacteristic odour.

Water White Standard

In Water White Standard, tanks are inspected internally, and Wall Wall Wash Test (WWT) is carried out. Tanks must be odour-free, clean, dry, and visually free of previous cargo residues and foreign matter. In Water White Standard Wall Wash colour test is carried out with methanol, acetone, and other suitable solvents. The acceptable result of this colour test is 15 or less.

High-Purity Standard

High-Purity Standard is commonly used for the carriage of Methanol cargo. This standard is often called the Methanol Standard. In High-Purity Standard, tanks are also inspected internally, and the Wall Wash Test(WWT) is carried out with methanol, acetone, and other suitable solvents. This standard also requires tanks to be clean, dry,odour-free, and visually free of previous cargo residues and foreign matter. The acceptable result values are mentioned below:

- Must pass water miscibility/hydrocarbon test

- Colour < 10 (APHA or ASTM D 1209)

- Permanganate time test(PTT) > 50 mins

- Chlorides must be less than 2 ppm

- UV spectrum passes

- Wash water is to be tested to confirm no more than 100PPM of the last cargo

Ultra-High Purity

The Ultra-High Purity standard requires a more stringent level of cleanliness than the High-Purity Standard. It is used for the carriage of extremely high-spec cargoes.

In Ultra-High Purity Standard, tanks are also inspected internally, and the Wall Wash Test(WWT) is carried out with methanol, acetone, and other suitable solvents. This standard also requires tanks to be clean, dry,odour-free, and visually free of previous cargo residues and foreign matter. The acceptable result values are mentioned below:

- Must pass water miscibility/hydrocarbon test

- Colour < 10 (APHA or ASTM D 1209)

- Permanganate time test(PTT) > 50 mins

- Chlorides must be less than 2 ppm

- NVM(Non-volatile matter) < 10 ppm

- The last cargo by gas chromatography or other suitable methods < 2PPM

- UV spectrum passes

- Wash water is to be tested to confirm no more than 100PPM of the last cargo

Note: Non-volatile matter and Gas chromatography tests cannot be performed on board. For more details about Cargo Tank Cleanliness Standards for Chemical Tankers, please refer to the INTERTANKO publication.

Items/Equipment required for Wall Wash Test (WWT)

- Spectrometer

- Methanol, acetone, and other suitable solvents laboratory grade

- De-ionised water(D.I. Water) laboratory grade

- Potassium Permanganate Powder(0.1g) for PTT (Permanganate Time Test)

- Hydrochloric Acid solution

- Sulphuric Acid – Lab Grade

- Nitric acid

- Silver nitrate

- Acidified silver nitrate solution (Optional)

- Chloride standard solution 10 PPM/ 500ML

- Disposable Latex gloves

- Graduated measuring glass cylinders with a metric scale calibrated to contain 50 &100 ml, with stopper and base – Nessler tubes

- Tube rack for Nessler tubes

- Cut Plastic & Metal funnels for WWT

- Sample bottles.(clear & dark 500ml)

- Nessler tubes 50 ml

- PH Paper

- Penlight

- Squeeze bottles with gooseneck

- Pipettes

- Filter paper

- Shoes cover

- Tissue Paper

- Sponge

- Thermometer

- Ice cool box (for holding PTT Samples)

- Cell glass for Spectrometer

- UV Cell Glass

Procedures and Types of Wall Wash Test (WWT)

Wall Wash Do’s and Don’ts

- Use a bucket or a backpack to carry the spray/squeeze bottles containing wall wash solvent, funnel, and labelled sampled bottles for each tank.

- Wear disposable latex gloves, shoe covers, and a clean or disposable boiler suit, along with personal protective equipment (PPE).

- Before taking wall wash samples, make sure to rinse all items in the bucket with methanol after entering each tank. This ensures cleanliness and avoids cross-contamination. Randomly select one spot on each bulkhead for the wall wash sample. With the funnel and sample bottle in one hand, direct the spray/squeeze bottle at least three feet above the funnel and collect the wall wash sample in the sample bottle. Collect approximately 50ml of wall wash from each bulkhead to have enough for testing purposes.

- Follow company-enclosed space entry procedures when entering the tanks.

- Don’t take samples from wet bulkheads.

- Always make a fresh standard solution for testing and clean all sampling tubes and pipettes before use.

- Avoid contamination of samples by human sweat, and always handle the samples with proper care, ensuring full cleanliness.

Types of Wall Wash Test (WWT)

Hydrocarbon (HC)/Water Miscibility Test

- For making a standard or reference solution: Add 10ml of the laboratory grade methanol and 90ml of Deionised water(D.I. Water) laboratory grade in a sample/nessler tube.

To make a test solution: Add 10 ml of the tank sample and 90 ml of Deionised water (D.I. Water) laboratory grade in a sample/nessler tube.

Note: Adding more methanol to DI water makes the hydrocarbon test progressively stricter. The dilution ratio depends on the company and load ports. Other commonly used ratios include (25:75, 33:67, and 50:50)

- Shake or Invert the nessler tube once or twice to mix the D.I. water and methanol.

- Now leave the sample/nessler tube and wait for 20 minutes.

- Place the tube on a black surface and switch off the lights. Use a penlight to shine through the side of the tubes while looking down through the liquid column.

- If a bluish tint is observed, it indicates slight hydrocarbons are present. If a whitish haze is observed, this usually indicates moderate to heavy hydrocarbons are present.

- If the sample is clear, this means no hydrocarbons are present.

- To check for specific hydrocarbons and chemicals, you can expose both the reference sample and the test sample to the UV light source in the spectrometer.

- A reading of 0 in the spectrometer indicates that the test has passed and no hydrocarbons are present.

- Factors that could affect this test are:

- Hazy test samples

- Dirty Column

- Damp bulkhead

- Sweat

Chloride (Cl) Test

- Using the same sample/nessler tube in which the hydrocarbon (HC)/water miscibility tests were conducted (if no hydrocarbons were found), add 5 drops of a 10% silver nitrate solution, and then add 5 drops of a nitric acid solution or use 5 drops of acidified silver nitrate solution

- Stopper the tube and invert it to mix the contents and wait for 15 minutes.

- Observe if any turbidity is formed by comparing the sample with the standard. Look down through the liquid against a black background to assess the turbidity.

- The comparison of wall wash samples to a standard should be performed in a darkened room by looking down through the tubes using a wide-beam penlight held about one foot from the sides of the tubes.

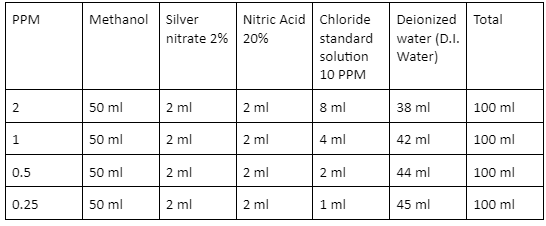

- For preparing a standard solution for the chloride solution:

6. Now we have both the standard solution and the wall wash sample ready to run into the spectrometer.

Note: Chlorides must be less than 2 ppm.

Permanganate time test(PTT)

- Thoroughly clean the sample/Nessler tubes with hydrochloric acid and rinse them three times with tap water. After that, rinse the tubes twice with deionised water and twice with methanol.

- Label the test tubes and add 50 ml of wall wash to each tube.

- Mix the permanganate solution by combining 0.1 grams of potassium permanganate with 500 ml of Deionised water(D.I. Water). Prepare a fresh solution every 3 days.

- Before adding the permanganate solution, fill the tubes to the 50 ml level with a wall wash.

- Place the tubes in a water bath maintained at 15°C±1°C if methanol is used, 25°C±1°C if acetone is used for ten minutes.

- Add 2 ml of the permanganate solution to each tube, stopper the tubes, and invert them once to mix.

- Prepare a standard solution using 50 ml of lab methanol and 2 ml of the permanganate solution to run simultaneously with the other tubes.

- Place the tubes in the water bath in a dark place and maintain the temperature.

- Observe the colour at 10-minute intervals and make a note of the times when the colour changes from deep purple to pink and when it fades to a pale, watery yellow and brown.

- If the standard fades at a shorter time than the test sample, it indicates a problem with the lab, methanol, permanganate solution, or testing containers.

- Now run the test in a spectrometer. For samples with a reading above 32.0%, they will show a pink colour and pass the test. For samples with a reading below 32.0%, they will appear brown in colour and fail the test.

Note: Permanganate time test(PTT) must be > 50 min.s

In addition to the aforementioned wall wash tests, other important tests are also carried out, such as

Visual Test: This test involves visually inspecting the sample under suitable lighting conditions to detect the presence of any suspended particles or visible impurities.

Odour Test: The odour test is performed to identify any persistent foreign odour that might contaminate the cargo. Filter papers are dipped into both the sample and the standard solution, and immediate smell detection is performed. It is crucial to avoid directly smelling from the tube, particularly if the previous cargo contained toxic substances.

Non-volatile Matter (NVM) Test: The NVM test aims to determine the presence of non-volatile impurities on the tank surface. A specific quantity of the wall wash liquid is evaporated, and the resulting residue (Non-volatile Matter) is weighed. The weight of the residue is then divided by the original sample weight to calculate the non-volatile matter content.

A test method is also available for determining the acid wash colour of various industrial aromatic hydrocarbons, including benzene, toluene, xylenes, refined solvent naphthas, and similar substances. This test provides a standardised procedure for assessing the acid wash colour of these hydrocarbons.

Wall Wash Test (WWT) vs Wash Water Analysis

We are almost at the end, and we hope you have understood the concept of the wall wash test.

Now, you might be wondering what exactly is wash water analysis?

Well, in tankers, seafarers have to make multiple entries into enclosed spaces to comply with wall wash criteria before reaching the loading port. However, due to the past fatalities associated with enclosed spaces, the industry is shifting from wall wash to wash water analysis.

Wash water analysis involves analysing the wash water that is pumped out of the tank using a spectrometer to determine if the tank is clean enough for the next cargo.

With wash water analysis, it is possible to monitor the tank cleaning process in real time during the actual cleaning operation.

This approach helps to reduce the actual washing of tanks based on a fixed time or physical inspection, as the cleanliness can be accessed through the measurement of the wash water itself.

You might also like to read-

- Differences And Correlation Between Spot Rates And Contract Rates in Shipping

- What are Trans-Shipment And Trans-Shipment Ports?

- What is a Skeg in a Vessel?

- 10 Things A Marine Engineer Should Check In A Lab Analysis Report Of Fuel Oil

Disclaimer: The authors’ views expressed in this article do not necessarily reflect the views of Marine Insight. Data and charts, if used in the article, have been sourced from available information and have not been authenticated by any statutory authority. The author and Marine Insight do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendations on any course of action to be followed by the reader.

The article or images cannot be reproduced, copied, shared or used in any form without the permission of the author and Marine Insight.

Do you have info to share with us ? Suggest a correction

Latest Shipboard Guidelines Articles You Would Like:

About Author

Bhupinder Marriya is an experienced seafarer currently serving as a Third Mate on chemical tankers. Holding a Second Mate Foreign Going COC (Indian), Bhupinder possesses extensive knowledge of tank cleaning operations, navigation, and cargo work, along with expertise in life-saving appliances and fire-fighting equipment (LSA & FFE). Combining his practical experience at sea with a passion for maritime education, Bhupinder actively contributes as a freelance writer, sharing valuable insights and educating readers about the maritime industry.

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Web Stories