9 Tips To Maintain High Efficiency of Marine Incinerators

Waste generation onboard ships is not a new phenomenon. With a whopping majority of seagoing vessels using HFO bunker as fuel, heavy amounts of sludge generation and operational waste is inevitable.

On an average, a 150000 GRT Very large Crude Oil carrier can generate as much as 0.8 metrics of sludge every day when running at its service speed. Sludge generation onboard can be as much as 1% of the fuel consumption every day.

Accumulating this waste sludge till the time the ship reaches the next port can be dangerous, unhygienic and also not economically feasible for making large storage tanks, thereby compromising on cargo capacity.

So where to put all the ship’s waste?

This makes the ship’s incinerator a piece of very important machinery on board.

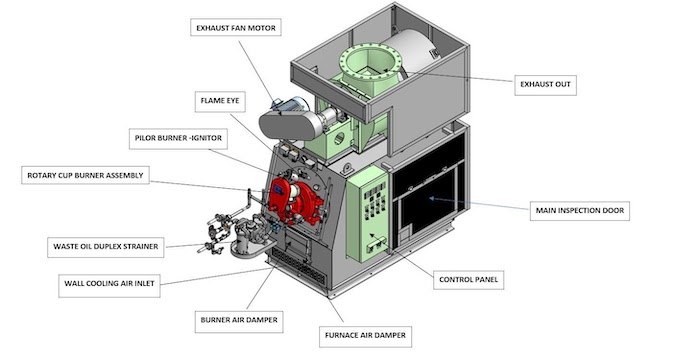

An incinerator is a machinery system in which we burn this waste sludge-coming from purifiers, Oily Rags, sometimes onboard waste paper, cardboard, waste oil generated in the engine room and other operational wastes as per MARPOL Annex VI, Regulation 16.

As per MARPOL Annex VI- Reg 16.7,16.8,

1) All Ships with incinerators shall possess manufacturer’s operating manual specifying how to operate it within limits.

2) Personnel responsible for operation shall be trained and capable of implementing the guidelines provided in the manufacturers operating manual.

Hence understanding the importance of this machinery in the engine room is a prerequisite for all crew.

All incinerators should be maintained in good working order with the best possible efficiency.

Why Maintain a High Incinerator Efficiency?

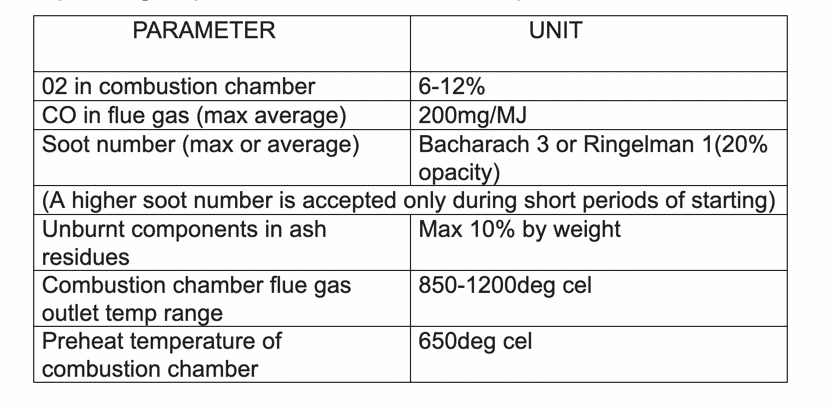

As per MARPOL ANNEX VI and as stated by the Marine Environment Protection Committee -MEPC.76(40)

1) Monitoring of combustion flue gas outlet temperature to be done at all times and waste shall not be fed into a continuous- feed type incinerator when the combustion chamber gas outlet temperature is below 850deg Celsius.

2) For batch loaded type, the combustion chamber gas outlet temperature shall reach 650deg Celsius within 5mins of starting and stabilize at a temperature above 850deg Celsius.

These temperature restrictions are to ensure that minimum black smoke is emitted at the time of starting due to incomplete combustion.

Incinerators onboard must not be used at ports, harbours and estuaries. However, special rules for incineration may be established by local authorities in some ports or special areas. To meet operational requirements, the incinerator may be used at anchorage provided it doesn’t interfere with local regulations.

This makes it very clear that in order to comply with the operating requirements and all regulations set by MARPOL, it is important to maintain the Incinerator at its best efficiency.

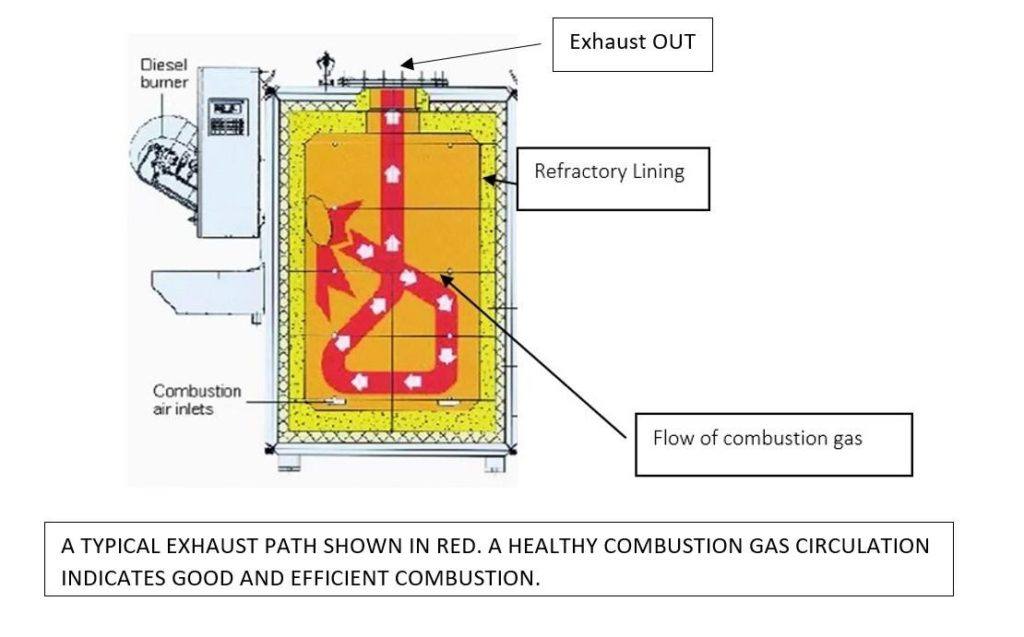

The incinerator continuously burns sludge(waste fuel) in the presence of air under partial vacuum conditions created by an induced draft fan. It is very important to monitor and control this air+fuel ratio to maintain optimum and continuous combustion. Maintenance of all combustion equipment responsible for firing and controlling airflow is equally important.

Tips To Maintain High Incinerator Efficiency

In order to get maximum efficiency from the incinerator, regular maintenance of combustion equipment is primarily necessary. We shall now see how we can increase the efficiency of the incinerator by monitoring and operating each component.

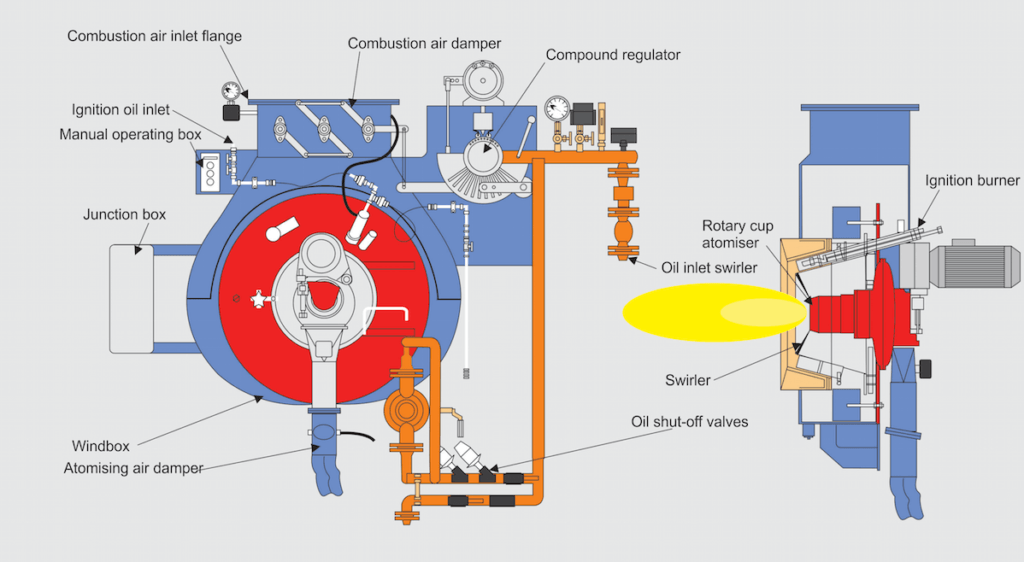

1) Rotary Cup Burner

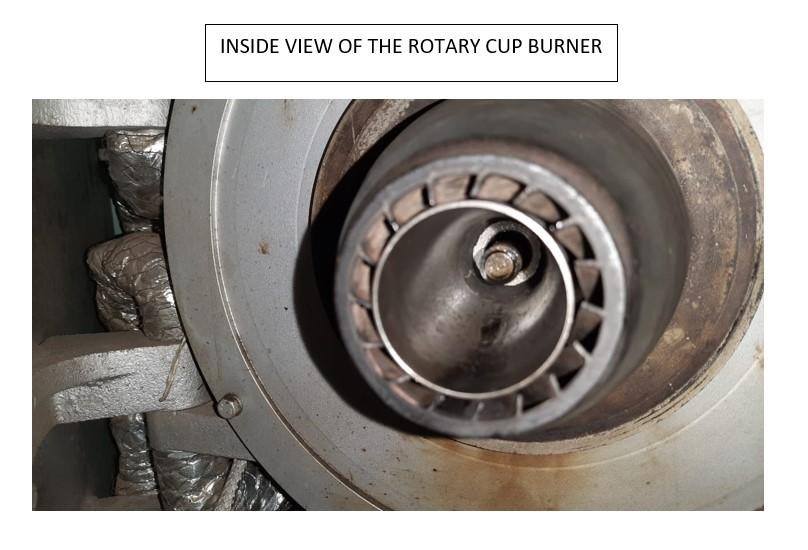

The burner forms the heart of the combustion equipment, which consists of atomizing parts, oil & air supply parts and driving parts.

The atomizer cup of the main burner should be cleaned after every running. The air nozzle of the main burner to be kept clear. Lubricant levels in the burner gearbox to be checked regularly.

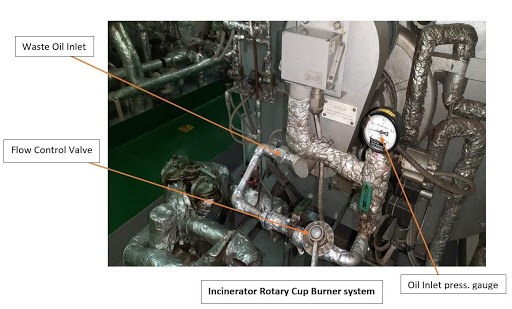

Waste oil inlet pressure can be adjusted by the supply pump relief valve setting, whereas the flow of oil can be adjusted by controlling the flow control needle valve just before the burner or the recirculation valve (if fitted in the supply line).

The driving belt for a belt-driven rotary cup burner to be checked regularly for wear or any kind of slackness. A worn-out belt may reduce the driving rotational speed of the rotary cup thereby affecting the fuel atomization pattern leading to incomplete combustion. The condition of the flame should be bright and yellow so as to not be able to see it with the naked eye.

Pilot Burner – The pilot burner or the ignitor consists of an atomizer nozzle, a small fine filter, 2 electrodes and electrode plugs and diesel oil piping. It gives the pilot flame in the form of a spark produced by an ignition transformer through electrodes, so as to ignite the main flame of the main burner. For quick ignition, the pilot burner atomizer should be clear of any contaminants and electrode distances should be as per manufacturer’s instructions. Otherwise, the pilot injection would be faulty leading to a misfire of the pilot flame.

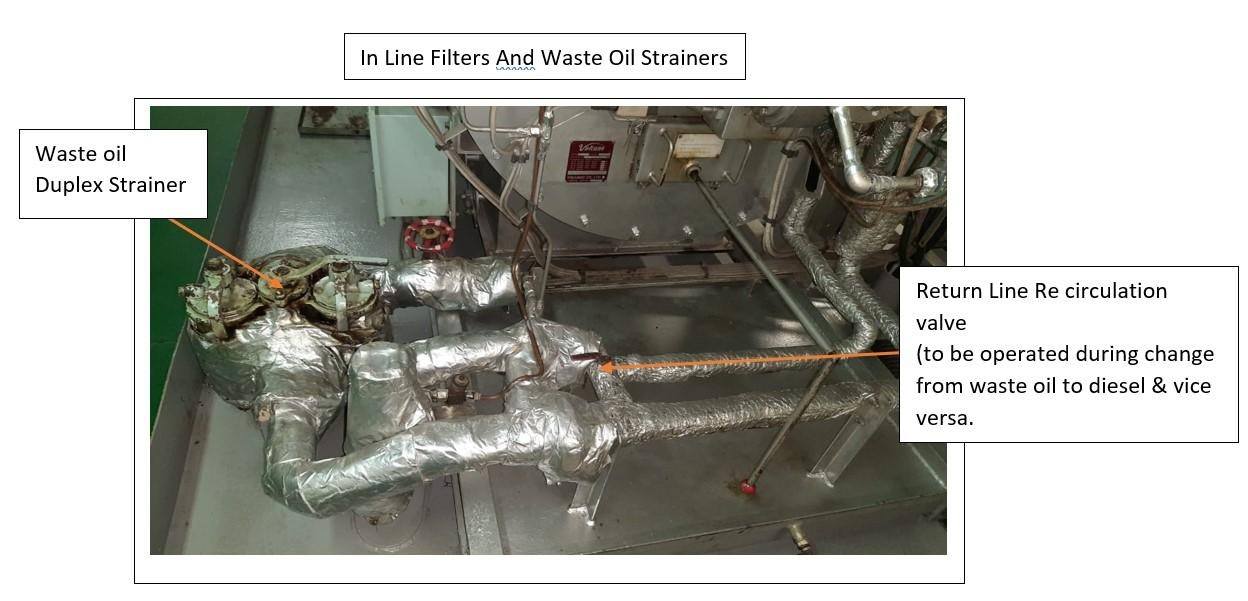

2) In-line Filters

Every incinerator will have a number of filters in its fuel supply line- usually a duplex waste oil strainer & a Y-type strainer for its pilot ignitor burner. These filters should be cleaned and the air is blown daily to avoid blockage of the fuel oil line by contaminants and maintain flow.

3)Adjusting of Furnace Air Damper

The damper is to adjust manually air to burn solid wastes in the combustion chamber. A wide opening may strengthen the fire but may delay an initial heating up of the chamber. This damper can also work in auto mode in certain incinerator models so as to dilute the combustion air in the furnace and control flue gas temperature. Secure the airflow for combustion and cooling, a hot chamber and good ventilation are necessary for substances to burn well with minimum smoke.

4) Adjusting of Burner Air Damper (Wind Box Damper)

The main burner is supplied with combustion air through the damper located under the burner on the wind box wall. Adjust it depending on the oil feed rate to get good combustion with minimum smoke.

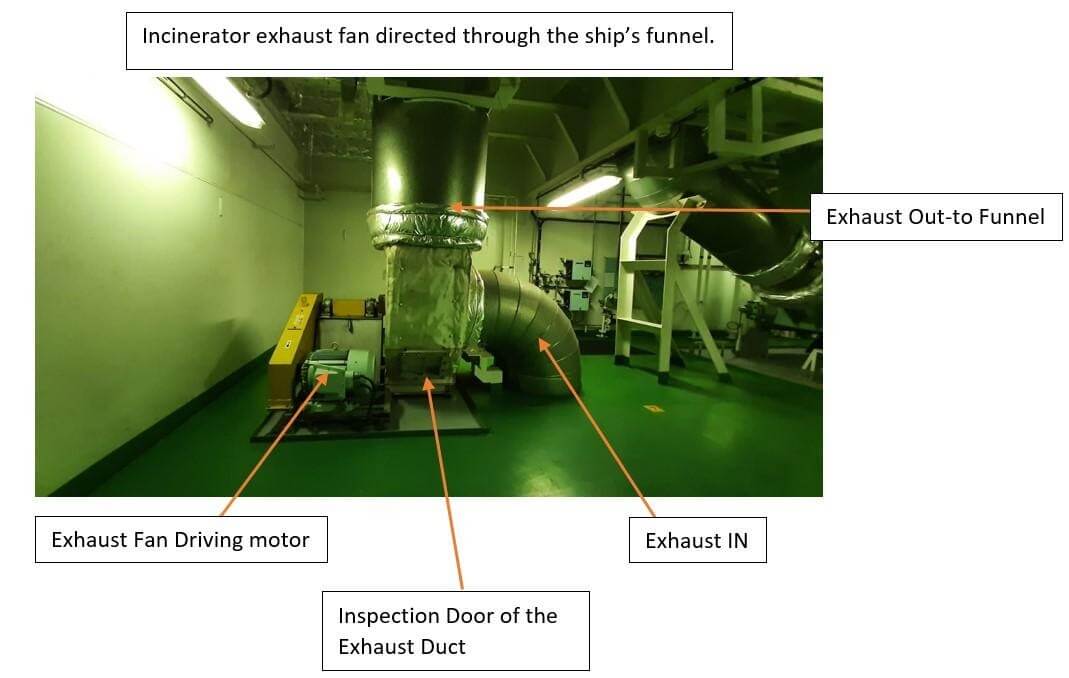

5) Exhaust Fan

Check that the exhaust fan is driven at an adequate draught so as to maintain negative pressure to the combustion chamber and ensure proper circulation of the exhaust gas and that gas cannot blow out of the chamber while in operation.

The exhaust gas duct leading to the ships funnel should be clear of any obstruction, at times pieces of cardboard fly off in the duct obstructing gas passage creating back pressure in the system.

6) Preparation For Water Oil Tanks Before Incineration

Sludge generated onboard is a mix of water and waste oil. It is very important to drain the layered water in waste oil tanks before burning. This can be done by evaporating its water content by heating through steam coils in waste oil tanks. Heating of waste oil also makes it easier to transfer and easier for atomization into fine fuel oil mist by burners. Proper oil temperature of waste oil at the burner inlet should be 90-100deg Celsius for efficient combustion. Waste oil tanks to be cleaned on board at regular intervals (3-6months as per PMS ) so as to clear out solid wastes in the tanks that settle down over a period of time.

It is advisable to maintain a constant recirculation of hot sludge if provided with a recirculation pump and a separate line. Continuous agitation of oil assists in better combustion.

7) Preparation of Solid Waste For Incineration

Solid wastes in the form of sludge generated during the main engine scavenge space inspections, stuffing box drain tank cleaning, scavenge drain tank cleaning, bilge tanks and waste oil tank cleaning, old engine system oils, general-purpose oily rags and waste paper/cardboard are often burnt in incinerators. It is often preferable to segregate large Sludge bags and make it to smaller quantities for incineration. Smaller charging lots will make combustion better and avoid excess soot formation in the furnace.

It is also advisable to not burn waste lube oil all at once because of its weaker combustibility and higher flashpoint. Waste management should be planned accordingly. Do not overcharge the incinerator and ensure good ventilation.

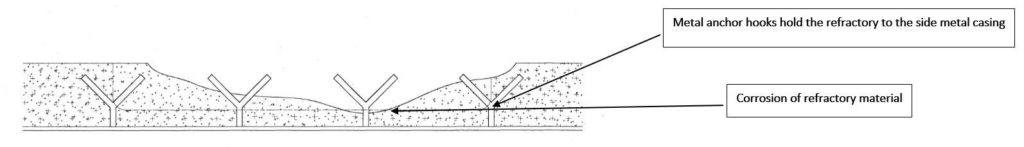

8) Care For Furnace-wall (Refractory)

The combustion process in the incinerator takes place in the furnace. The lining of the furnace is made up of refractory material which contains heat and combustion gases inside the chamber. Damaged refractory exposes the bare metal casing causing loss of heat transfer and loss of efficiency in operating the incinerator. To avoid refractory damage, it is advisable to avoid temperature fluctuations in the furnace. Variations in temperature can cause differential expansion between metal casings & refractory material, leading to cracks and promoting corrosion. Refractory patching up repair is required to be done in case of refractory damage.

9) Flushing for the waste oil line with diesel oil before and after

It is always a good practise to run the incinerator on diesel oil for the first 5mins till the combustion temperature reaches about 650deg Celsius and then changeover to waste oil by interchanging the fuel supply valves & operating the change-over cock provided in the return line. Similarly, before stopping Diesel oil should be used to flush the waste oil line to make sure that all lines are clear and free from contaminants.

These are one of the main factors to keep in mind while operating an incinerator so as to gain maximum performance with the best efficiency.

Do you have any other best practices in mind that you did onboard?? Feel free to comment below.

Disclaimer: The authors’ views expressed in this article do not necessarily reflect the views of Marine Insight. Data and charts, if used, in the article have been sourced from available information and have not been authenticated by any statutory authority. The author and Marine Insight do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendation on any course of action to be followed by the reader.

The article or images cannot be reproduced, copied, shared or used in any form without the permission of the author and Marine Insight.

Do you have info to share with us ? Suggest a correction

Latest Marine Technology Articles You Would Like:

- 10 Harmful Effects Of Impure Air On Ship’s Machinery

- 10 Important Things to Check While Starting Fuel Oil Purifier on Ships

- 10 Noteworthy LNG-Powered Vessels

- 10 Points for Efficient Turbocharger Operation On Ships

- 10 Practical Tips to Handle Engine Room Pumps

- 10 Precautions to Take Before Operating Controllable Pitch Propeller (CPP) on Ships

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Web Stories