Pipes and Bends – An Essential Guide for Second Engineers: Part 2

In our previous article (Pipes and Bends –Part 1) we discussed the difference between a pipe and a tube, meaning of nominal diameter and schedule of a pipe. In this article, we will discuss bends, elbows and miter bend.

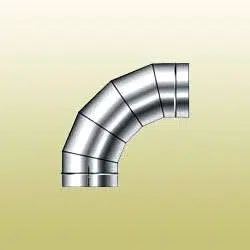

Bend or Elbow

There is always a doubt about the terms bends and elbows on ships. They are frequently used as synonyms. The difference between them is as follows:

- Bend is a generic term for any offset or change of direction in the piping. It is a vague term that also includes elbows.

- An elbow is an engineering term and they are classified as 90 deg or 45 deg, short or long radius.

- Elbows have industrial standards and have limitations to size, bend radius and angle. The angles are usually 45 deg or 90 degrees. All others offsets are classified as pipe bends.

- Bends are generally made or fabricated as per the need of the piping; however, elbows are prefabricated and standard and are available off the shelf.

- Bends are never sharp corners but elbows are. Pipe bending techniques have constraints as to how much material thinning can be allowed to safely contain the pressure of the fluid to be contained. As elbows are prefabricated, cast or butt welded, they can be sharp like right angles and return elbows which are 180 degrees.

- Elbow is a standard fitting but the bends are custom fabricated.

- In bends, as the pipe is bent and there is no welding involved, there is less pipe friction and flow is smoother. In elbows, the welding can create some friction.

- All elbows are bends but all bends are not elbows.

- Bend has a larger radius than elbows.

- Generally, the most basic difference is the radius of curvature. Elbows generally have a radius of curvature between one to twice the diameter of the pipe. Bends have a radius of curvature more than twice the diameter.

Short Radius and Long Radius

Elbows are again classified as long radius or short radius elbows. The difference between them is the length and curvature. A short radius elbow will be giving the piping a sharper turn than a long radius elbow.

- In a long radius elbow, the radius of curvature is 1.5 times the nominal diameter. In a standard elbow, the radius of curvature is 1.0 times the nominal diameter of the pipe.

- Long radius elbows give less frictional resistance to the fluid than short elbows.

- Long radius elbows create lesser pressure drop than short radius elbows.

- Short radius is less costly than long radius elbows.

- The short radius elbows are used where there is a scarcity of space.

The 45 degrees elbow turns the fluid /piping at 45 degrees and so on.

Miter bends

Another type of bend is a Miter bend. A Miter bend is a bend that is made by cutting pipe ends at an angle and joining the pipe ends. A true miter bend is a 90-degree bend made by cutting two pipes at 45 degrees and joining them by welding. Similarly, three pipes cut at 22.5 degrees will give a 90 degree miter bend.

In the next article, we will discuss various pipe fittings.

References

- PIPE FITTINGS BY SAFELOK-USA

- Stainless steel tube

- Engineering tool box

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication – By J. Phillip Ellenberger

- Schsm

Do you have info to share with us ? Suggest a correction

About Author

Chief Engineer Mohit Sanguri is a Marine Chief Engineer (Class I Unlimited Power). He has 12+ years of experience as a Marine Engineer.

Latest Marine Technology Articles You Would Like:

- 10 Harmful Effects Of Impure Air On Ship’s Machinery

- 10 Important Things to Check While Starting Fuel Oil Purifier on Ships

- 10 Noteworthy LNG-Powered Vessels

- 10 Points for Efficient Turbocharger Operation On Ships

- 10 Practical Tips to Handle Engine Room Pumps

- 10 Precautions to Take Before Operating Controllable Pitch Propeller (CPP) on Ships

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

thank u… it was a useful information.

May I use your articles to teach my Marine Engineer class?

Our school is San Jacinto Maritime College

You can see me under Faculty.

I would like to put this material in our text book for Pumpman.

Thanks,

USA 713-882-9164

Hey Mohit Sanguri,

I was poking around Marineinsight today and came across your article:

“Pipes and Bends – An Essential Guide for Second Engineers: Part 2”.

I noticed that you mentioned “Difference between Pipes and Tubes” from Engineering tool box in the reference. I also love that article.

In fact, it inspired me to create a more thorough and up to date version:

https://www.hysteelpipe.com/steel-knowledge/15-difference-pipe-tube/

I’d be tickled pink if you’d consider adding it to your page.

Best Regards,

Jason Ho

Best explanation, I have ever seen thanks Mohit

I personally don’t know very much about pipe bending so this article was very helpful. I never realized that there were so many things to take into account before bending a pipe like having a short radius or long radius elbows. I never realized that bending is better for flow than welding is.

What’s from corrosion and pitting aspect?