What’s The Criteria For Reuse or Replacement of Auxiliary Engine Connecting Rod On Ships?

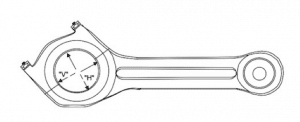

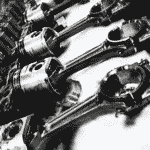

The power generated by the piston in the combustion chamber of marine engine is transferred to the crankshaft using the connecting rod. While transferring this tremendous power, the connecting rod itself is subjected to different stresses, which makes is vulnerable to damage. For this reason connecting rod bolts are used to join the connecting rod and con-rod bearing cover under the tremendous stresses generated by the running engine.

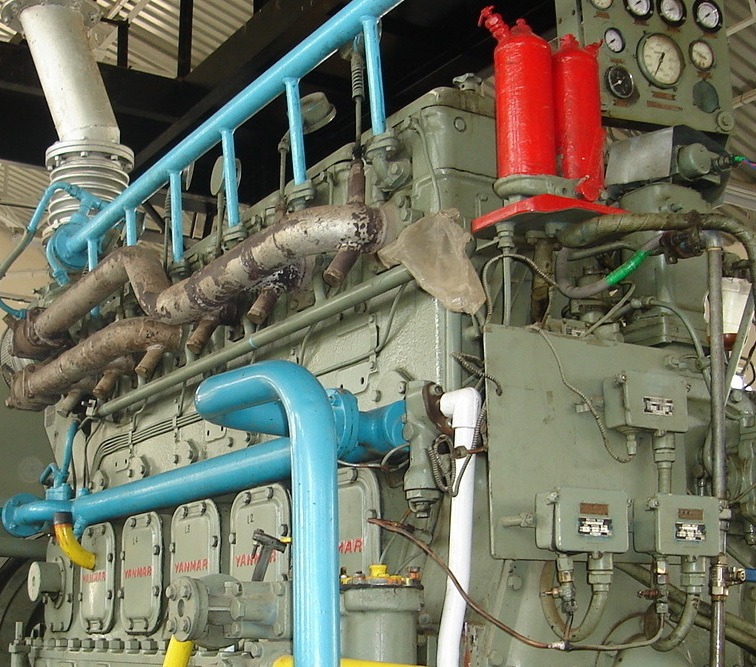

The most common type of connecting rod that is used in the ship’s auxiliary engine is oblique or cross-cut connecting rod which is made of two parts.

The connecting rod of the engine must be inspected at regular intervals of time to ensure there is no defect or problem to avoid any future accidents/emergency. It’s the knowledge and skills of the engineer that decides whether to use the same connecting rod or to renew it with the spare one.

Following points must be considered when checking the connecting rod for re-use or replacement:

1. Check the ovality of the connecting rod: Check the ovality of the connecting rod by tightening both parts at its rated torque. Inside micrometer is used to determine the correct and current ovality of the connecting rod. If the ovality is out of limits, the connecting rod is not to be reused.

2. Check connecting rod for fretting and corrosion: Connecting rod to be checked for fretting and corrosion. If fretting is small, it can be removed by using oilstone. Never use grinder or scrapper for this purpose. Con-rod with severe fretting and racks must be discarded.

3. If connecting rod with fretting is to be used, check for cracks: Minute fretting can be tolerated over the connecting for reuse only if the surface does not have any cracks. If the fretting is in small area and oil stone is used to treat the same, the complete area must be checked again by using magnaflux which detects small hairline cracks which are not visible to the naked human eye.

4. Check cracks between connecting rod and bearing cover: The serration and bore between connecting rod and bearing cover to be checked for cracks by using die penetrating crack detection test. Rod to be used only when there are no cracks detected. If there are small cracks in the connecting rod bearing cap serration, renew it with new spare one.

5. Renew connecting rod and connecting rod bearing cover together: Connecting rod and connecting rod bearing cover to be renewed as a whole. Never renew single part of the connecting- rod in case of damage as the serrations are machined in pair to locate the two halves relative to one another.

6. Re-machining of serrations should not be done: Re-machining of serrations of connecting rod /bearing cap or bore should not be done even if there is minute damage or indentation.

7. Bearing shell with fretting at its back should not be used: Bearing shell with fretting at it’s back side must not be used with connecting rod and it is to be renewed in set.

8. Ensure bolts and bearings are of same type during replacement: If the connecting rod is replaced, it should be of same type and same con-rod bolts and bearings to be used. Ensure to read the older generator data to confirm the bearing size (undersize or oversize) to be fitted while renewing the shell.

9. Replace Connecting Rod Bolts in Sets: Connecting rod bolts to be used and replaced in sets. If the connecting rod is renewed with the spare one, the con-rod bolts from the old con-rod must not be used with the new spare connecting rod.

10. Correct sequence and tightening torque: Once it is decided to reuse or replace the connecting rod, the engineer office must ensure that he knows the correct assembling sequence (front/ back side, pair of con-rod and bearing cap etc. ) and rated tightening torque is applied on the con-rod bolt with step- by-step tightening procedure as listed in the manual.

The assessment of connecting rod for reusing/ discarding is a critical decision to make for the ship’s engineer officer. A slight mistake in making the correct choice may lead to major generator damages and sometimes even causality.

The above mentioned are some of the important basic checks which should be performed by the engineer to upkeep the generator’s long life and efficient performance.

Do you know any other important point that can be added to this list?

Let’s know in the comments below.

Do you have info to share with us ? Suggest a correction

Latest Marine Technology Articles You Would Like:

- 10 Situations When Ship’s Generator Must be Stopped Immediately

- 10 Important Tests for Major Overhauling of Ship’s Generator

- 8 Important Points To Note For Maintenance Of Emergency Generators On Ship

- Understanding Different Operational Modes Of Shaft Generator On Ships

- Ways of starting and testing emergency generator

- What’s The Criteria For Reuse or Replacement of Auxiliary Engine Connecting Rod On Ships?

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Web Stories

About Author

An ardent sailor and a techie, Anish Wankhede has voyaged on a number of ships as a marine engineer officer. He loves multitasking, networking, and troubleshooting. He is the one behind the unique creativity and aesthetics at Marine Insight.

some marine auxilary engines for eg yanmar(2oo L UN) also one methode to check connecting rod deformation is passing 8mm straight rod through oil hole to make sure not obstructing any where .this also a measument indicates ovality.

@ Madan:

Yes, this method is adopted for yanmar and other makers too. It is used to check the trueness (straightness and bend) in the connecting rod and not for ovality. You have to use inside micrometer to check the ovality of the big end.

After installation you need further check side motion of connecting rod by a screwdriver. If can move freely, it will be ok. If can not move, it should be replaced by a new one.

Perhaps by oversight, the importance of checking the piston gudgeon pin & the associated bushing during overhauls has been overlooked.

Some Yanmar models and other auxiliary engine makers also recomends to change the con-rod bolt each 20000 hours because them can suffer elongations

The elongation of the con rod bolts needs to be checked and if beyond limit is supposed to be renewed.

However most of the Chief Engineers prefer to change after 24000 hours.

How to check if the connecting rod is bent

@Manikanadan: Please check this article – https://www.marineinsight.com/tech/generator/10-important-tests-for-major-overhauling-of-ships-generator/

How we check elongation of bottom end bolt if new bola r nt available to compare?

What is purpose of serration and what preventive measure has to be taken to safeguard con rod serrated face film development?? plz help.

@Akshay: Serrations are used to locate the two halves relative to one another.

yanmar

We strong recommend renew connecting rod nuts with connecting rod bolt for same timing.

Because the nuts was extended only little with 20000hrs.

If you didn’t renew connecting rod nuts with new connecting rod bolts.

It’s possibility new connecting rod bolts will get damage for part of screw.

Sir in my meo class 4 oral the surveyor asked ne how to check the con rod of generator is bend . I tell him the wire method in which a thin wire is inserted inside the lub oil hole of con rod if it goes smoothlt the it’s ok and if there is any restrictions in it’s movement then it is bend. But the surveyor said this is not the method for that. So can u tell me the method for that

@Kumar Animesh: The word to be used should be – “ROD” and not “WIRE” as wire can easily bent and take the shape of deformed connected rod. For e.g. in Yanmar Generator connecting rod deformation is checked by passing 8mm straight rod through oil hole to make sure not obstructing any where . If it does not stuck in between, the rod is ok.

VERY USUFUL ARTICLE INDEED

What’s the replacement criteria for the renewal of hydraulically tightened connecting rod bolts on Hyundai 6H21/32 engine.