K-Line Signs Agreement For Next Generation Offshore Wind Turbine Demonstration Project

Electric Power Development Co., Ltd. (J-POWER),1 Tokyo Electric Power Company Holdings, Inc. (TEPCO HD),2 Chubu Electric Power Co., Inc. (Chubu Electric),3 Kawasaki Kisen Kaisha, Ltd. (“K” LINE),4 and Albatross Technology Inc. (Albatross),5 have entered into a joint research agreement for a next-generation (floating axis) offshore wind turbine demonstration project (the “project”).

The Japanese government has announced the intention to maximize the adoption of renewable energy sources as part of the nation’s commitment to achieving carbon neutrality by 2050. Offshore wind power, in particular, is considered a vital part of the initiative to make renewables a primary source of power due to the potential for large-scale installation, lower cost, and economic ripple effects.

In Japan, with limited shallow sea areas, there is growing interest in floating offshore wind power because it can be deployed in deep water. To promote the widespread adoption, it is essential to significantly reduce costs through technological development. In addition, increasing the ratio of domestic production (in Japan) is expected to create a strong economic ripple effect.

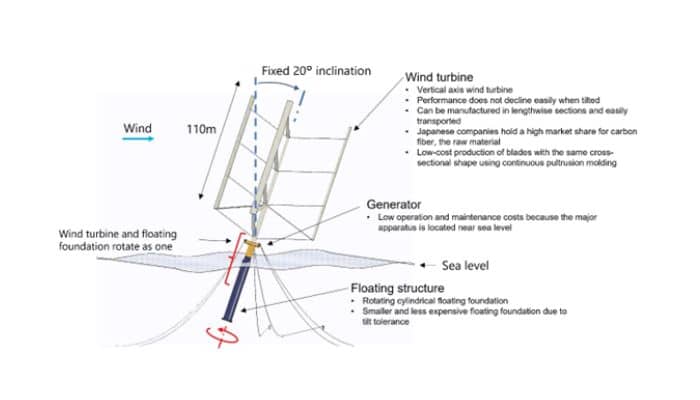

(Courtesy of Albatross Technology Inc.)

Against this backdrop, the five partnering companies in this demonstration project will jointly develop a small-scale (20kW) next-generation experimental floating axis wind turbine that is expected to reduce costs and increase the domestic production ratio.

The floating axis wind turbine (FAWT) is a concept under which a vertical-axis wind turbine is supported by a “rotating” cylindrical floating foundation. Its main features are as follows:

Cost Reduction

The wind turbine can be tilted 20 degrees at maximum output, as it is designed to maintain effectiveness even when tilted. This allows for downsizing for the floating foundation and a significant reduction in equipment costs.

The wind turbine section can be manufactured at low cost through continuous pultrusion,6 a molding process used to form composite materials into long shapes, with carbon fiber reinforced plastics (CFRP).

By taking advantage of the characteristics to install vertical axis wind turbines close to sea level due to their specific characteristics, operation and maintenance costs for the major apparatus are also anticipated to be substantially lower.

Increase in Domestic Production Ratio

The wind turbine blades can be manufactured in lengthwise sections with the same cross-sectional shape, eliminating the need for large-scale manufacturing facilities. Additionally, this design makes sections easier to transport, and is therefore suited for domestic production.

Japanese companies hold approximately 80% of the market share for carbon fiber, the raw material used in the carbon composite for the wind turbine.

J-POWER, Osaka University’s Graduate School of Engineering and Albatross are jointly conducting initial studies of the FAWT concept. Embarking on the tests signifies the next step under a new framework. For the project, small-scale experimental versions of the FAWT will be installed in Japanese waters. After confirming the validity of the analysis and design method, this will lead to an even larger scale (megawatt class) offshore demonstration project.

The five companies involved in the project will use their individual expertise to jointly develop the FAWT, which is anticipated to be a “game changer” in floating offshore wind power generation. Through this collaboration, we aim to make offshore wind power generation the primary source of electricity and contribute to the realization of a carbon-neutral society.

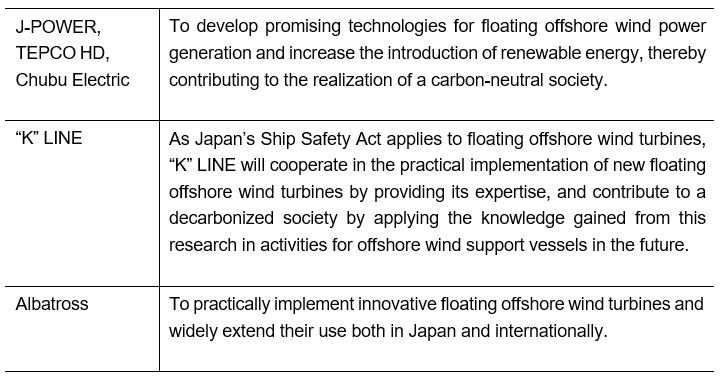

Goals of participating companies:

Cooperating Organizations

The wind turbine section of the small-scale experimental units will be developed by Fukui Fibertech Co., Ltd. (Aichi Prefecture), and the floating section will be developed by Mirai Ships Inc. (Miyagi Prefecture). The carbon composite material molding technology will be developed in partnership with the Innovative Composite Center (ICC) at the Kanazawa Institute of Technology, and the motion analysis technology will be developed in partnership with Osaka University’s Graduate School of Engineering.

Notes:

1. Electric Power Development Co., Ltd. (headquartered in Chuo-ku, Tokyo; President: Toshifumi Watanabe)

2. Tokyo Electric Power Company Holdings, Inc. (headquartered in Chiyoda-ku, Tokyo; President: Tomoaki Kobayakawa)

3. Chubu Electric Power Co., Inc. (headquartered in Nagoya City, Aichi; President: Kingo Hayashi)

4. Kawasaki Kisen Kaisha, Ltd. (headquartered in Chiyoda-ku, Tokyo; President: Yukikazu Myochin)

5. Albatross Technology Inc. (headquartered in Chuo-ku, Tokyo; CEO: Hiromichi Akimoto)

6. A molding method for continuously manufacturing components with the same (fixed) cross- section by solidifying the resin and fibers as they are drawn through a mold

Press Release

Disclaimer :

The information contained in this website is for general information purposes only. While we endeavour to keep the information up to date and correct, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability or availability with respect to the website or the information, products, services, or related graphics contained on the website for any purpose. Any reliance you place on such information is therefore strictly at your own risk.

In no event will we be liable for any loss or damage including without limitation, indirect or consequential loss or damage, or any loss or damage whatsoever arising from loss of data or profits arising out of, or in connection with, the use of this website.

Disclaimer :

The information contained in this website is for general information purposes only. While we endeavour to keep the information up to date and correct, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability or availability with respect to the website or the information, products, services, or related graphics contained on the website for any purpose. Any reliance you place on such information is therefore strictly at your own risk.

Do you have info to share with us ? Suggest a correction

About Author

Marine Insight News Network is a premier source for up-to-date, comprehensive, and insightful coverage of the maritime industry. Dedicated to offering the latest news, trends, and analyses in shipping, marine technology, regulations, and global maritime affairs, Marine Insight News Network prides itself on delivering accurate, engaging, and relevant information.

About Author

Marine Insight News Network is a premier source for up-to-date, comprehensive, and insightful coverage of the maritime industry. Dedicated to offering the latest news, trends, and analyses in shipping, marine technology, regulations, and global maritime affairs, Marine Insight News Network prides itself on delivering accurate, engaging, and relevant information.

Latest Shipping News Articles You Would Like:

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.