Case Study: Increasing The Accuracy And Efficiency Of Bilge Water Monitoring

This case study looks at a package of upgrades an international commercial fleet undertook to ensure the efficiency of their bilge water monitoring. AtZ were asked to check all on-board Deckma monitoring equipment was working as effectively, reliably and securely as possible to ensure and future-proof IMO environmental compliance.

Type of project: New Install

INTRODUCTION

For many years commercial operators have demanded the highest standard of environmental compliance for their bilge water overboard discharge technology. As part of the on-board separator monitoring equipment, our customer selected the Deckma Hamburg OMD-24 monitoring unit.

As sole UK and EIRE agents for Deckma equipment, ATZ have been supporting commercial vessels for over 20 years’ and have supplied, installed, maintained and commissioned the Deckma equipment on-board serveral hundred vessels.

HOW IS OIL-IN-WATER MEASURED

The IMO MARPOL standard measures oil in water content in ppm (parts per million) and describes the concentration level of oil within the water. One ppm is therefore equivalent to 1 millilitre of oil per 1000 litres of water, 0.001%.

The IMO states that no bilge water is to be discharged into the sea that has an oil content that exceeds 15ppm.

EXISTING INSTALLATION

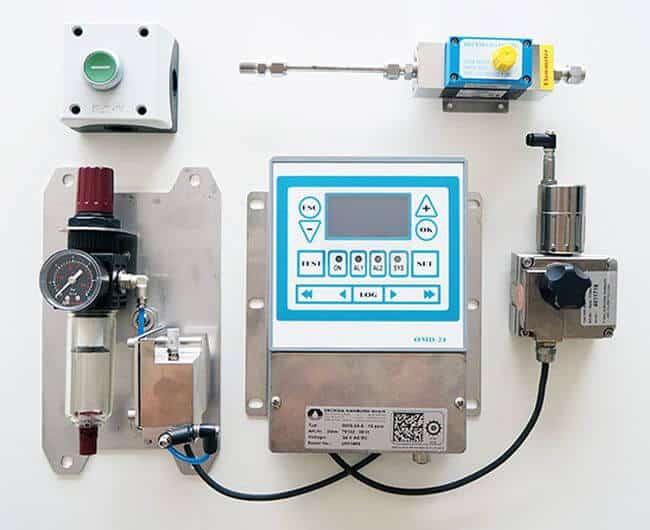

The OMD-24 monitoring system consists of:

The computer unit which receives and displays the oil contamination ppm reading and provides alarm information and data output. The computer unit determines whether the cleaned bilge water can be discharged overboard.

The calibrated measuring cell measures the oil content of a sample of the cleaned bilge water intended for overboard discharge and then relays the information to the computer unit.

The measuring cell also has a line in for fresh water supply which can be activated to clean the cell periodically. This is due to dirty sample water, which can lead to oily build up and artificially high ppm readings.

CHALLENGES

- Cleaning: To keep the measuring cell clean requires a crew member to activate the valve for fresh water flushing via an option within the unit’s computer menu. Failure to flush the unit results in a dirty measuring cell that could give artificially high ppm readings, which is why initial training of crew is required, along with regular refreshing of knowledge.

- Cleaning: Even when the fresh water flush is enabled periodically, the sample bilge water dirt may still build up, requiring periodic, manual cleaning of the cell with a brush.

- Flow rate Monitoring: It is technically feasible to create a no flow situation within the measuring cell. If the static water in the cell is below the required ppm level, the computer unit will not alarm and will not prevent overboard discharge, even if the bilge water is over the legal ppm limit.

Our customer pro-actively opted to pursue Deckma system upgrades to ensure the best possible up-time of the separation and monitoring equipment, and to ensure that they continue to adhere to environmental monitoring legislation fully.

AtZ suggested the following methods to allow both the users and vessels to continue to be legislation compliant:

Cleaning:

ATZ commissioned a manual override cleaning button that meant any crew member could merely press and hold the button at any time when in the proximity of the on-board separator and monitoring equipment. The result is a ‘cleaner for longer’ measuring cell, increasing the cleaning intervals while improving the accuracy of ppm readings.

Cleaning:

ATZ commissioned an automatic cleaning system, which consists of a pneumatically activated, electromagnetically controlled wiper seal that cleans the inside of the cell. The computer unit controls the time interval at which the wiper seal is enabled and is configurable by the operator. The result is a ‘cleaner for longer’ measuring cell, reducing the frequency of manual cleaning and delivering accurate ppm readings.

Flow Rate Monitoring:

Working with our customer, ATZ quickly understood the need to monitor the flow rate through the cell. Working with Deckma head office, ATZ designed, manufactured, tested and installed the first flow switch upgrade within six weeks. The result is a system that will alarm at a flow rate below the pre-set limit, preventing any overboard discharges when there is no sample flow through the measuring cell.

CONCLUSION

The conclusion of this project ensured our customer is fully compliant to current IMO regulations while providing them with technology that positioned them at the forefront of bilge water monitoring – future-proofing their business for environmental compliance, far ahead of industry and competitor standards.

Press Release: AtZ

Disclaimer :

The information contained in this website is for general information purposes only. While we endeavour to keep the information up to date and correct, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability or availability with respect to the website or the information, products, services, or related graphics contained on the website for any purpose. Any reliance you place on such information is therefore strictly at your own risk.

In no event will we be liable for any loss or damage including without limitation, indirect or consequential loss or damage, or any loss or damage whatsoever arising from loss of data or profits arising out of, or in connection with, the use of this website.

Disclaimer :

The information contained in this website is for general information purposes only. While we endeavour to keep the information up to date and correct, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability or availability with respect to the website or the information, products, services, or related graphics contained on the website for any purpose. Any reliance you place on such information is therefore strictly at your own risk.

Do you have info to share with us ? Suggest a correction

About Author

Marine Insight News Network is a premier source for up-to-date, comprehensive, and insightful coverage of the maritime industry. Dedicated to offering the latest news, trends, and analyses in shipping, marine technology, regulations, and global maritime affairs, Marine Insight News Network prides itself on delivering accurate, engaging, and relevant information.

About Author

Marine Insight News Network is a premier source for up-to-date, comprehensive, and insightful coverage of the maritime industry. Dedicated to offering the latest news, trends, and analyses in shipping, marine technology, regulations, and global maritime affairs, Marine Insight News Network prides itself on delivering accurate, engaging, and relevant information.

Latest Shipping News Articles You Would Like:

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.