What Are Container Tracking Systems?

An estimated 32 trillion USD worth of cargo changed hands in global business operations last year. Of this, about 29 trillion worth were transported across the globe using multimodal containers, either dry or refrigerated.

Around 23 million Twenty Equivalent Units (TEUs) crisscrossed the oceans and overland to achieve this phenomenal cargo movement. With that being said, how do vendors and business operators keep track of their cargo? It could be on the high seas, at the port of loading, or discharge.

Keeping Track of Consignments

How does keeping track of containers help in doing business? In a nutshell, it can be said that it helps business houses take critical decisions. Besides, business houses are not the only ones to benefit from such a system. Carriers, as well as ports and terminals, also rely very much on container tracking systems to plan and arrange the movement of cargo ships and consignments.

In a perfect world, assuming the seller has dispatched goods to his customer as per their agreement and in good condition, it departs the port of origin and reaches the destination port as promised and arranged. However, inclement weather and delays at ports due to labour issues or infrastructure breakdowns are quite common these days. These two important factors can affect the expected time of departure (ETD) of cargo vessels and, as a result, the expected time of arrival (ETA) of containers at the destination ports.

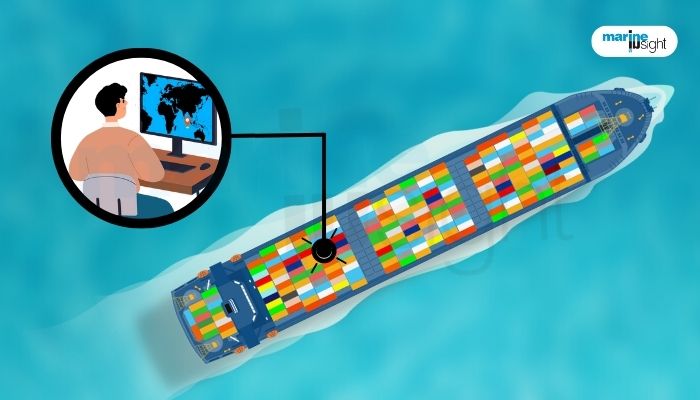

Efficient and real-time container tracking systems help stakeholders locate the exact whereabouts of their cargo.

If the buyer and seller have access to their cargo carrier’s container tracking system, then all that is required is to key in the bill of lading number or the container number to show the current location of their container. Knowing where a consignment is during the flow of cargo from the port of origin to the destination aids both these parties. Monetary risks caused by delays in receiving consignments can be reduced considerably by taking immediate action.

Let us look at the main scenarios where cargo tracking helps the parties involved in the trade and transport of goods.

Stack Dates

Container tracking systems help carriers and port terminals in taking decisions. Stack date is a window of time, usually between 2 to 5 days, within which containers – both loaded as well as empty containers have to reach the port for loading on board a cargo vessel. Outbound containers that do not make it to the port within the given stack dates may miss sailing resulting in the delay of the consignment.

Stack dates are decided by the port authorities in consultation with the carrier. The work of a stack date planner is based on the ETA, and ETD received from shipping lines through their container tracking systems. Well-planned stack dates help avoid container traffic pile-ups.

An accurate container tracking system plays a major role in keeping these parties informed on the whereabouts of containers meant for transhipment and delivery. Containers that are ready to be loaded onboard cargo vessels for sailing and those that have been unloaded from incoming vessels are stored temporarily at container yards (CY). Such yards plan their activities based on stack dates.

Container tracking systems help carriers to plan, retrieve, and reposition their containers once discharged and offloaded at the destination port.

Demurrage and Detention

Many large business organisations often sell their products in advance, even before receiving them at the port of discharge, as in the case of imported goods. Major product promotions are arranged in advance, anticipating stocks that have been ordered. In the event of any delay in receiving goods, it is the logistics department of that company that always faces the heat. Hence, the ETA updated by the carrier has to be realistic and accurate.

Clearance of containers is usually a priority for logistics operations failing which the received containers start accumulating demurrage after a certain number of days. Demurrage is charged to the customer by the carrier to cover port costs when it is not cleared within a specified time.

The free storage period varies between dry and refrigerated containers and between the different ports. Similarly, when there is a delay in releasing an empty container after unloading, the carrier will levy a charge on the customer. This is called detention. Carriers charge detention as well as demurrage per container per day.

Telex Release

In an earlier article, we have seen that a Telex Release is the release of a consignment to the customer without having to submit the Bill of Lading (BL) at the port of discharge. This usually happens when goods are shipped over short distances, and there is no time for the original shipping documents to be sent and received between the seller and buyer or the Notify Party.

A Telex Release is based on electronic or digital confirmation that the original bill of lading has been surrendered to the carrier at the port of origin. Periodic updates from a real-time container tracking system help buyers and sellers with visibility of their containers from loading to discharge. The buyer or consignee at the discharge port can plan for immediate port clearance based on this information and thereby avoid demurrage.

Enterprise Resource Planning Systems (ERP)

Most shipping companies have container tracking systems as part of an ‘all-encompassing’ ERP system. Such ERP systems aid in freight rate dialogues between carrier and client, bill of lading software, document control, etc., besides cargo container or consignment tracking.

A client may be given secure access to log on to the relevant portal in such an ERP system to get the necessary details of their consignment. Updates in the form of short text messages (SMS) or periodic emails further help the client stay in touch with his consignment.

The biggest advantage of having access to an online container tracking system is that stakeholders have real-time information on their containers that can be accessed anytime on the internet. It does away with the need for phone calls and other forms of messages, increasing productivity. Such a tool mitigates delays.

A leading example of a tracking tool is the one found in CARGOES Flow by DP World. It is an enterprise multi-vendor tracking tool to track and trace air, land, and sea cargo using a single window.

Most leading cargo shipping companies, such as the AP Moller – Maersk Group, Mediterranean Shipping Company (MSC), COSCO, CMA CGM Group, etc., offer easy-to-use container tracking systems to their customers and clients.

You might also like to read-

- What Are Stack Dates in Shipping?

- What is ETD and ETA in Shipping?

- What is Demurrage and Detention in Shipping?

- Telex Release – Everything You Wanted to Know

- NOTIFY PARTY in Shipping – Everything You Wanted To Know

Disclaimer: The author’s views expressed in this article do not necessarily reflect the views of Marine Insight. Data and charts, if used in the article, have been sourced from available information and have not been authenticated by any statutory authority. The author and Marine Insight do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendations on any course of action to be followed by the reader.

The article or images cannot be reproduced, copied, shared or used in any form without the permission of the author and Marine Insight.

Do you have info to share with us ? Suggest a correction

About Author

Hari Menon is a Freelance writer with close to 20 years of professional experience in Logistics, Warehousing, Supply chain, and Contracts administration. An avid fitness freak, and bibliophile, he loves travelling too.

Latest Maritime law Articles You Would Like:

Latest News

- What is the Purpose of DG Shipping?

- What are Logistics Risks?

- How Port and Terminal Operators Can Control Emissions?

- Minimum Quantity Commitment (MQC) and Liquidated Damages in Container Shipping: Concept and Relevance

- MARPOL (The International Convention for Prevention of Marine Pollution For Ships): The Ultimate Guide

- The Ultimate Shipping Container Dimensions Guide

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.