How Are Steel Coils Loaded On Ships?

It is not wrong to say that steel is one of the primary foundations of the global economy. This widely popular iron alloy is one of the widely produced, fabricated, transported, and consumed materials in the current-day supply chain.

Steel is utilised in diverse forms for countless purposes ranging from industrial to agricultural, domestic to urban, and infrastructural to product-based.

According to reports, global steel production has increased more than ten times over the last 70 years and is slated to reach astronomical levels in future.

This results from a population boom, globalisation, burgeoning infrastructural developments, escalated production, diversified supply chain, and of course, ever-increasing demands from all sectors. Steel and various steel products are crucial elements in global trade and play a pivotal role in the economic growth of any nation.

Transportation of Raw Steel

After extraction of hot steel from blast furnaces in steel furnaces, the steel is cold-hardened and processed further to improve strength, quality and other surface and internal material properties.

After that, it is shaped or moulded into slabs, ingots, sheets, billets, etc., for further utilisation. This process is also known as the casting of steel.

Processed bulk steel in these forms is then carried to a steel mill or other production facility. It is then made into commercial standard plates, bars, rods, beams, profiles, channels, pipes etc.

After the early stages of steel production, there are two kinds of rolling processes in a steel rolling mill. The hardened steel in the raw or semi-processed form is then cast into different forms:

- Hot Rolling

- Cold Rolling

In hot rolling, the steel is heated to very high temperatures (till red hot) and rolled. In cold rolling, the steel is cooled off rapidly and is treated at low temperatures to improve surface and mechanical properties.

After cold rolling, steel is ready for utilisation from a material point of view. After partial processing of bulk steel after hot rolling or complete processing of steel after cold rolling, the steel is often wound up and rolled up into large coils for convenient transport and storage.

A coil of steel composed of a hot-rolled or semi-processed steel coil is known as a hot-rolled coil, and this needs to be further treated and cold-rolled for usage. Hot-rolled steel coils are often rolled after annealing. Similarly, a coil of steel made up of cold-hardened and rolled or fully processed steel is known as a cold-rolled coil.

Once again, they have superior surface and mechanical properties ready to be used in the market after suitable shaping into various items as desired. These steel coils can be unwound again and either be further processed or cold-rolled (for hot-rolled coils) or fabricated into different products or items (for cold-rolled steel coils).

Most of this steel is carried in cargo vessels as steel coils for convenience. The transport of this steel makes up a considerable portion of the freight market in the commercial supply chain.

We are also familiar with these vast cylindrical coils being handled at cargo terminals and transported through land routes on trucks and trailers.

But specific regulations and guidelines are abiding by which the proper stowage and transport of these coils in large quantities are carried out in ships.

Loading Steel Coils On Ships

These steel coils are usually shipped in bulk and stowed accordingly onto the vessel’s designated cargo holds. These steel coils weigh around 40-50 tons. So, before loading, it must be ascertained that:

- The holds are swept, cleaned with fresh water and dried thoroughly. All remaining residuals, like rust, debris, flakes, and other contaminants, should be removed. Also, any remaining gases must be stripped off the holds before loading. Per regulations, a ‘cleaning certificate’ should be obtained from third-party providers after the cargo hold cleaning process.

- Pre-loading surveys of the steel coils are essential.

- Assessing the integrity and water tightness of the cargo hold, the integrity of the hatches and openings, and ventilation and loading cranage systems.

- A thorough inspection of the cargo holds and carefully marking sharp edges or points.

- Ascertaining the presence of loading and securing manuals with a suitable loading plan. Though, for all practical purposes, as per SOLAS VI regulations, securing manuals should be present for all types of cargo, steel coils are not specifically under any form of definite framework. So, it is the responsibility of the operator and freight managers to ensure that they are stowed safely, securely, and adequately, and optimising the maximum amount of space available.

Loading and Unloading Procedure

The loading process is carried out meticulously with the help of cranes and derricks, both on-board and those present in the cargo terminals or ports. The coils are usually lifted through their geometric centre, where the suspension point is typically braided steel wire wraps or slings. Tying chains are avoided to prevent damage to the steel surface.

A maximum level of care is taken to ensure that the coils remain unharmed and are unscathed on their surfaces (especially cold-rolled and finished ones). When these coils are handled using forklifts, round or circular lifting section tines are used as conventional rectangular ones with sharp edges, which can harm steel surfaces or distort the coil centre.

Coils are always placed such that they are axially oriented with the longitudinal direction of the ship; that is, their circular centroid always faces the fore-aft direction of the vessel.

They are permanently wedged at the bottom in a transverse direction to prevent rolling motions and damage. To avoid damage to the steel surface and ensure sufficient friction to stop the coils from rolling, they are usually placed on wooden planks arranged in the transverse direction, known as dunnages.

They are usually about 25-30 mm thick and act as an intermediate layer between the coils and the ship’s plating. Furthermore, they can absorb a significant amount of the structural loads from the coils before they are uniformly distributed over the vessel’s structure.

These dunnages are carefully dried beforehand to ensure that any form of moisture that can pose a risk of causing rusting and corrosion to the steel coils are absent. The securing wedges, in turn, are further pinned to ascertain that any motion present in the coils during the voyage is arrested, and the resultant dynamic loading is transferred to the vessel’s structure.

For all practical purposes, the loading coils are always placed in designated cargo holds and never on the deck or any other part above the strength deck. The loading is done accordingly to ensure optimal space utilisation but not abnormal or non-uniform loading of the coils.

Furthermore, the dunnages are also carefully placed in a way such that the weight of these coils is not transferred to unstiffened spans of the plating (that may result in localised static, dynamic and fatigue loads) but on the bottom shell plating or inner bottom plating (for double bottom vessels) as a whole as line-distributed loads where the maximum amount of loading is tended to be enacted on the stiffening and deep members.

On the flip side, this is problematic as this causes the overall loading to not comply with the loading information specified in the information and cargo guidance manuals. But for all practical purposes, the steel coils are usually carried on large bulkers or other general-purpose carriers that are adequately strengthened and have high design load values.

Similarly, during unloading, the wedges and lashings are all unlocked carefully, and the coils are lifted by cranage equipment one by one starting from the topmost layer in a fashion similar to that of loading.

Stowage and Securing

After loading the steel coils, stowage and securing is another essential aspect. Steel coils vary in size and weight. So, from the first principles, their stowage philosophy is the same as any other form of cargo. They are stowed in the lower holds and loaded from bottom to top for a more significant number of such oils.

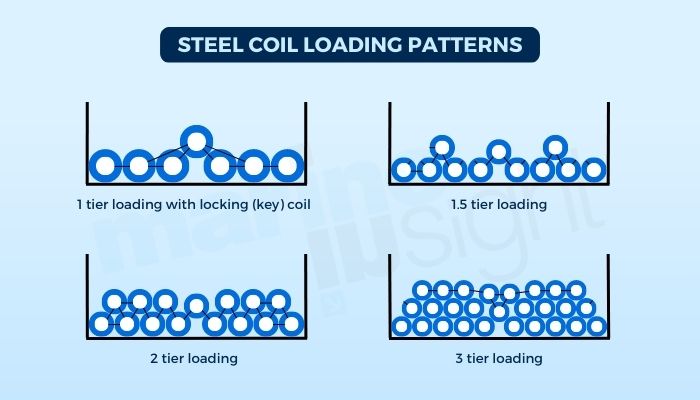

To keep the centre of gravity below feasible limits of vertical position, the heavier coils are loaded first and kept at the bottom regions and the lighter or smaller ones at the top. The coils are strapped or banded to one another using suitable securing arrangements.

They are positioned in athwartships and in multiple tiers or levels for a greater number of coils. Between two successive layers, the coils are strapped to each other. For multiple rows of coils stowed, there is a minimum clearance of 4 to 6 inches between two rows to avoid contact forces and any damage during loading and unloading procedures.

A central coil, also known as the key coil, is chosen in a central location both in a horizontal and vertical sense, with steel strappings directed to both the adjacent and the steel coils situated below.

The strappings are hard metallic, are in taut conditions, and are often pneumatic in modern arrangements. Any key coil resting on a bottom layer of coils is lashed and positioned.

The bottom edge of the diameter is below the top tip of the bottom coil by at least one-third of the geometric diameter of the latter; however, it should not exceed 60% of the diameter of the top or key coil.

You might also like to read-

- Difference Between Lifeboats and Rescue Boats

- Understanding Block Coefficient Of A Ship

- What Is Moulded Depth Of A Ship?

- Understanding The Beam Of A Ship

Disclaimer: The authors’ views expressed in this article do not necessarily reflect the views of Marine Insight. Data and charts, if used, in the article have been sourced from available information and have not been authenticated by any statutory authority. The author and Marine Insight do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendations on any course of action to be followed by the reader.

The article or images cannot be reproduced, copied, shared, or used in any form without the permission of the author and Marine Insight.

Do you have info to share with us ? Suggest a correction

Latest Shipboard Guidelines Articles You Would Like:

About Author

Subhodeep is a Naval Architecture and Ocean Engineering graduate. Interested in the intricacies of marine structures and goal-based design aspects, he is dedicated to sharing and propagation of common technical knowledge within this sector, which, at this very moment, requires a turnabout to flourish back to its old glory.

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.