Accommodation Ladder On Ships – Requirements, Operations and Maintenance

The accommodation ladder is a one point access to ship’s deck for shore personal, port lashing/cargo crew and seafarers. Just like any other deck equipment, the accommodation ladder is used in port, at sea, or in anchorage for getting pilot/ crew onboard ship or vice-versa (The same purpose can be solved by the gangway of the ship as well).

Though the accommodation ladder appears to be a simple system, its installation and maintenance procedures are strictly regulated by the ship’s crew. Needless to say, any accident related to accommodation ladder directly involves ship or shore personnel using the same.

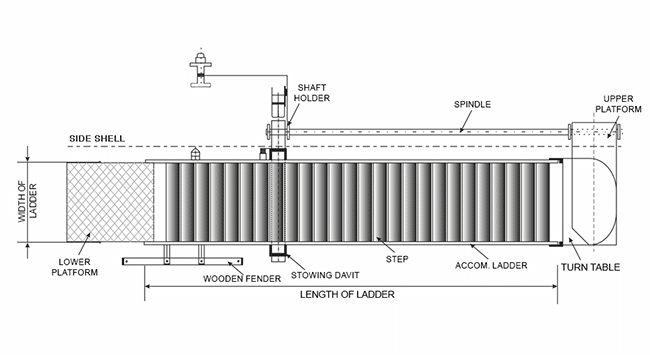

Understanding the General Arrangement of Accommodation Ladder On Ship:

General arrangement of accommodation ladder on ship is as follows:

- Two opposite hands accommodation ladders are permanently fitted on both port and starboard side of the ship at upper deck level, adjacent to crew accommodation area

- The system is such constructed that the accommodation ladder can be stowed 90 degree to its rigged position, close to the ship’s hull

- It usually comes with fixed steps and foldable aluminium handrails outside ladder stringers

- It is flexible enough to be rigged either alongside or parallel to any of the ship’s sides or at an angle with the lower platform moved away from the ship with its quay roll resting on the jetty

- The upper platform of the ladder (inboard platform) can revolve around the fixed shipboard arrangement

- An electric spindle is used to move the ladder in and out of ship’s side

- The accommodation ladder is suspended by use of wires and telescopic hoisting arm connected to an individual ladder winch on both sides, and it can be electrically or manually driven

- Both side ladders are remote controlled by a push button remote box

- The telescopic hoisting arm is fitted in such a way that it does not collide with the container gantry crane

Regulations and Requirements Of Accommodation Ladder

- As far as practicable, the means of embarkation and disembarkation should be sited clear off the working area and should not be placed where cargo or other suspended loads may pass overhead

- Adequate lighting should be provided to illuminate the means of accommodation ladders on both sides

- A lifebuoy equipped with a self-igniting light and a buoyant lifeline should be available for immediate use in the vicinity

- The arrangement at the head of the accommodation ladder should provide direct access between the ladder and the ship’s deck by a platform securely guarded by handrails and adequate handholds.

- The ladder should be securely attached to the ship to prevent overturning.

- Each accommodation ladder should be of such a length to ensure that, at a maximum design operating angle of inclination, the lowest platform will be not be more than 600 mm above the waterline in the lightest seagoing condition

- Each accommodation ladder or gangway should be clearly marked at each end with a plate showing the restrictions on the safe operation and loading, including the maximum and minimum permitted design angles of inclination, design load, maximum load on bottom end plate, etc.

- A safety net should be mounted in way of the accommodation ladders and gangways as a person may fall from the means of embarkation and disembarkation or between the ship and quayside

Checkout the Basic Difference Between Gangway and Accommodation ladder

Operation of Accommodation Ladder:

Rigging of Accommodation Ladder-

For rigging the accommodation ladder, following points must be kept in mind

- Ensure the rigger has don all important PPE’s including life jacket and safety harness

- Switch on the electrical power supply to the winch

- Remove lashing from the accommodation ladder which is used to tie it up in stowed position

- Using the remote control, lower the ladder by pushing the down button

- Because of the spring buffer, the ladder will cant to its horizontal position first. Continue lowering the ladder till it reaches 2m below the hoisting arm

- Strat positioning the hand railings and stanchions on the upper platform first

- Continue positioning the hand rails on the ladder and connect it to the upper platform hand railings

- Now rig the lower platform and positions the stanchions on the same

- Put safety nets around the rigged ladder

- If required, slew the ladder over the quay to achieve required position using electrical spindle

Hoisting and Stowing of Accommodation Ladder:

- Ensure the operator has don all important PPE’s including life jacket and safety harness

- Use the electric spindle to bring the ladder close to ship side

- Connect the upper platform to the torque tube (if disconnected)

- Hoist the accommodation ladder using remote control by pushing UP button till 2 m below the hoisting arm

- Rig the lower platform in horizontal position and remove the stanchions

- Fold the handrails from both side of the ladder

- Remove railings and stanchions from the upper platform

- Now continue hoisting the ladder until it has been canted in to the recess

- Fasten the lash the accommodation ladder

- Switch off the electrical supply to the winch and remote control

Maintenance, Checks and Surveys

It is very important to continuously monitor and perform regular planned maintenance on the accommodation ladder.

The general maintenance, which needs to be performed are:

- General inspection of ladder, platforms, lashing, wire and permanent fixtures

- All greasing points must be greased regularly with seawater resistant grease which will include:

- Various hoisting sheaves on the ladder

- Hoisting sheaves on davit arm

- Hoisting sheaves on steel structure

- Wire ropes

- Monthly inspection of wire which will be recorded in the log book

- Renewal of wire due to deterioration of the falls or at intervals of not more than five years, whichever is earlier

Caution:

Nowadays, the gearbox is filled with “Lubrication for Life”, hence do not empty and refill. If needed, contact the manufacture for assistance

If the stanchions of the ladder are fitted with nylon bearings, they did not need any greasing

Checks and Surveys:

Following are annual checks which needs to be performed as per SOLAS regulations I/7 and I/8 on accommodation ladder: .

- steps

- platforms

- all support points such as pivots, rollers, etc.

- all suspension points such as lugs, brackets, etc.

- stanchions, rigid handrails, hand ropes and turntables

- davit structure, wire and sheaves, etc. and

- any other relevant provisions stated in these guidelines

On gangway:

- treads

- side stringers, cross-members, decking, deck plates, etc.

- all support points such as wheel, roller, etc.

- stanchions, rigid handrails, hand ropes

- any other relevant provisions stated in these guidelines

Annual surveys required for winch:

- Survey of brake mechanism including condition of brake pads and band brake, if fitted

- Survey of remote control system

- Survey of power supply system (motor)

The Five Yearly survey will include operational test with the specified maximum operational load of of accommodation ladder and gangway winch. The load used for the test should be:

- the design load, or

- the maximum operational load, if this is less than the design load and marked, or

- the load nominated by the shipowner or operator only in those cases where the design load or maximum operational load is not known (e.g., for accommodation ladders or gangways which are provided on board ships constructed prior to 1 January 2010), in which case that nominated load should be used as the maximum operational load for all purposes

The tests should be carried out with the load applied as uniformly as possible along the length of the accommodation ladder or gangway, at an angle of inclination corresponding to the maximum bending moment on the accommodation ladder or gangway.

Disclaimer: The authors’ views expressed in this article do not necessarily reflect the views of Marine Insight. Data and charts, if used, in the article have been sourced from available information and have not been authenticated by any statutory authority. The author and Marine Insight do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendation on any course of action to be followed by the reader.

The article or images cannot be reproduced, copied, shared or used in any form without the permission of the author and Marine Insight.

Latest Shipboard Guidelines Articles You Would Like:

Do you have info to share with us ? Suggest a correction

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Web Stories

About Author

An ardent sailor and a techie, Anish Wankhede has voyaged on a number of ships as a marine engineer officer. He loves multitasking, networking, and troubleshooting. He is the one behind the unique creativity and aesthetics at Marine Insight.

Thanks for informative safety guidelines. I would like to add one more is do not overreach/use ladder with the winding height for the job and do not carry heavy objects with both hands while going up or down a ladder.

@Vipul: Important Point. One hand to self and one hand for the ship.

Many gangways don’t have angle indicators fitted to illustrate the angle of inclination. Are you aware of a portable measuring device to do such?

Nowadays we are arriving ports with pre rigged optimised gangway safety net and is acceptedby most ports without a fully installed net throughout the port stay.

Which regulations allow as to do so to rig optimised net instead of full net