Real Life Incident: Mooring Line Parts And Hits Deck Officer Causing Multiple Skull Fractures

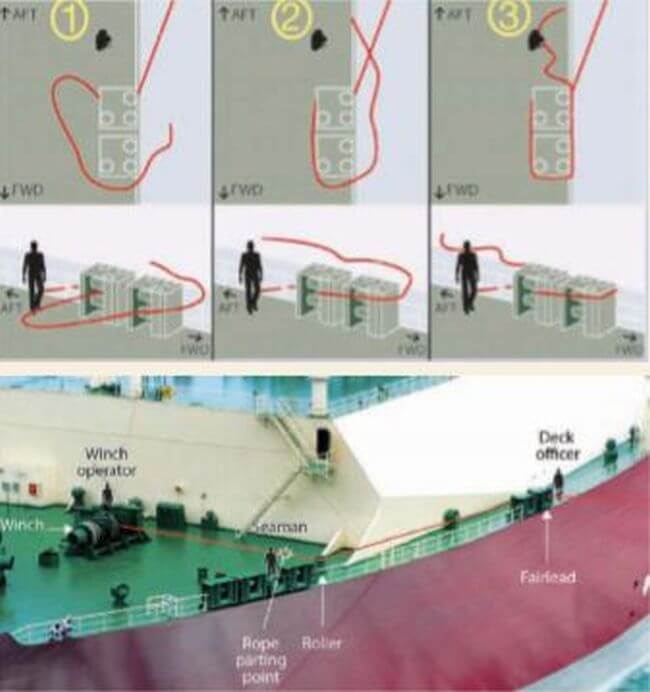

A large LNG carrier was being warped into position by tensioning the forward back springs. The deck officer in charge of the forward mooring party was standing aft of the fairlead through which the spring lines passed. He was directing operations by signalling to a seaman who was located forward. From this position, the seaman was able to relay the signals to the winch operator, who could not see the deck officer.

The mooring line parted inboard from a pedestal fairlead while under tension. The section of the line between the break and the port shoulder roller fairlead struck the deck officer on the head as it whipped back before going overboard through the fairlead. The deck officer was found lying unconscious forward of the roller fairlead. He had sustained multiple skull fractures.

The mooring line that failed was a 44-millimetre diameter sheathed ultra-high-modulus polyethylene (HMPE) line. The line was fitted with a 22-metre polyester/polyethylene tail. The section of line in use between the winch and the connection with the tail was approximately 68 metres long.

The MAIB report found, among other things, that:

- The residual strength of the mooring line was substantially reduced from original specifications. The tensile load on the mooring line when it parted was less than a quarter of its specified minimum breaking load and below its accepted working load limit.

- The predominant factor for the loss of residual strength was axial compression fatigue. However, axial compression fatigue had not previously been considered as a likely failure mode or significant cause of strength loss in HMPE rope by the manufacturer.

- The decision to attempt to reposition the vessel using the spring lines rather than recalling the tugs placed the mooring parties in an unnecessarily hazardous position, particularly given the strength and direction of the winds.

Lessons Learned

- Mooring line maintenance management and condition monitoring regimes must include clear and practical criteria for discarding compromised ropes.

- The condition of the load bearing core of jacketed ropes cannot be adequately assessed on board ship. Several of the rope discard criteria listed in the company’s safety management manual, such as broken strands, abraded yarns and fused fibres, cannot be identified without destroying sections of the rope.

- The tensile strength of high modulus rope will diminish steadily over time regardless of how well it is maintained. For this reason, appropriate safety factors and anticipated life expectancies need to be applied, and parameters such as time, tension and temperature need to be closely monitored. Without these, the ropes will likely fail before being discarded.

Press Release: nautinst.org

Do you have info to share with us ? Suggest a correction

About Author

Marine Insight News Network is a premier source for up-to-date, comprehensive, and insightful coverage of the maritime industry. Dedicated to offering the latest news, trends, and analyses in shipping, marine technology, regulations, and global maritime affairs, Marine Insight News Network prides itself on delivering accurate, engaging, and relevant information.

About Author

Marine Insight News Network is a premier source for up-to-date, comprehensive, and insightful coverage of the maritime industry. Dedicated to offering the latest news, trends, and analyses in shipping, marine technology, regulations, and global maritime affairs, Marine Insight News Network prides itself on delivering accurate, engaging, and relevant information.

- Real Life Incident: Vessel Collision in Good Visibility

- Real Life Incident: Severe Injury To Deck Crew While Leaving Berth

- Real Life Incident: Departure Damage in Very Restricted Waterway

- Real Life Incident: Low Situational Awareness Has High Impact Consequence

- Real Life Incident: Fouled Anchor in a Designated Anchorage

- Real Life Incident: Fire On Barge Carrying Scrap Metal Causes $7 Million Worth Of Damage

Latest Case studies Articles You Would Like:

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.