Real Life Incident: Incinerator Ends Junior Wiper’s Sea Career

The second engineer distributed the day’s work to the engine room staff, verbally instructing the junior wiper to burn the garbage in the incinerator. He was familiar with the job, having done the task for the last seven months. A little while later, the fourth engineer went up to the incinerator room to check the safety parameters of the equipment. He found all systems in satisfactory condition and so he returned to the control room. The junior wiper was standing outside the incinerator room waiting for the combustion temperature to reduce prior to loading the second garbage pack.

About 30 minutes later the junior wiper rushed to the Master’s office; he had sustained very deep burns to his left palm. The vessel was diverted to an anchorage and the junior wiper disembarked for medical treatment. All five fingers of his left hand were badly burnt and after assessment by doctors, four fingers were amputated. The junior wiper had to return to his home country for further reconstructive treatment. To all intents and purposes, his seagoing career was over.

The company conducted an investigation and found the following:

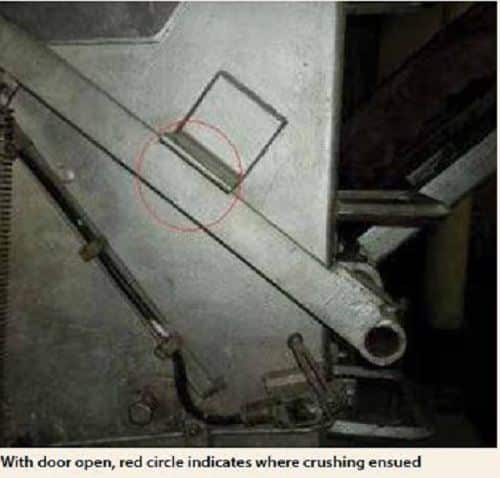

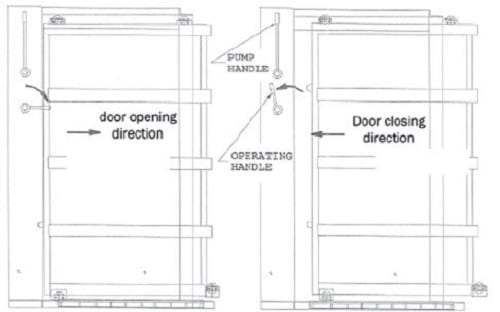

It appears the junior wiper, because of his small stature, had always used a bench to better access the incinerator door. Also, in this case he may have tried to push an oversized garbage bag down the incinerator sluice with a long handled poker. To do this, the junior wiper had to hold down the incinerator door micro switch (to simulate a closed door) and press ‘start sluice action’, all while trying to push the bag down.

Lessons learned

Proper training and supervision are critical with operations such as incineration.

Incineration on this ship is best undertaken by two persons.

Ship-specific Job Hazard Analysis should be done for incineration, as for all vessel activities.

Under normal conditions, safety devices such as micro switches should never be ‘tricked’.

Note: According to the company, ship’s personnel interviewed during the investigation indicated that the use of a bench to access the incinerator was not a safe practice. Yet this practice had been tolerated for many months and was never identified as a non-conformity or unsafe practice during the course of work or during safety meetings. This indicates some important latent unsafe conditions contributing to this accident: a less than adequate safety culture and poor safety leadership.

Do you have info to share with us ? Suggest a correction

- Real Life Incident: Vessel Collision in Good Visibility

- Real Life Incident: Severe Injury To Deck Crew While Leaving Berth

- Real Life Incident: Departure Damage in Very Restricted Waterway

- Real Life Incident: Low Situational Awareness Has High Impact Consequence

- Real Life Incident: Fouled Anchor in a Designated Anchorage

- Real Life Incident: Fire On Barge Carrying Scrap Metal Causes $7 Million Worth Of Damage

Latest Case studies Articles You Would Like:

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

i am a Director (ret) Engineering & Ship Surveys, Dept. of Marine Administration, Ministry of Transport 1972/1990, Yangon, Myanmar and I like to keep updated with present day trends and Marine Engineering Related Accidents and Enquiries and Oreventions & Improvements etc.

Did MLC helped seaman or owener?

To me MLC has only helped owener and P&I club.

Before MLC was enforced it was said labour laws will be applied to seaman also. Nothing has happened after that.

Is MLC fully implemented or still some things are left?

Pls comment.

But risk assesment and hot work permit has been done? If so, no problem then. Case closed.

GREAT !!!!!!!!! ALL MARINE ENGINEERS SHOULD SHARE THEIR DAY TO DAY EXPERIENCE.

Make and Model of the Incinerator would be helpful. God bless his recovery. I was wondering what could be the cause. Incinerator doors generally have a “OPEN” interlock. When properly shut, the garbage is then passed to the combustion chamber. I am not trying to blame anyone, just trying to find the cause, so i can implement similar safety on my ship.