Real Life Incident: Engine Cadet Loses Life Due to Phosphine Gas Leak in Cabin

A handy-sized bulk carrier was loaded with wheat, and the cargo was fumigated after completion of loading.

When the fumigation procedure was undertaken, the hatch covers, ventilators and access hatches to all five cargo holds were sealed. The vessel then departed for a trans-oceanic voyage.

The crew had been briefed on the dangers of fumigation gas and the Master told the crew to stay alert for the smell of garlic or decaying fish as this scent had been added to the gas to allow easy detection.

During the first three days of the voyage, phosphine gas readings were taken at regular intervals at the upper deck accommodation and the forecastle deck. All readings were zero ppm.

On the fourth day, the gas test results showed that the accommodation on the upper deck contained 0.1 ppm of phosphine gas. (According to best practices, an eight-hour average respiratory exposure to phosphine gas should not exceed 0.3 ppm and a short-term exposure should not exceed 1ppm.)

On the same day, a crew member remarked that he had noticed a bad odour inside his cabin. A test in the cabin showed no phosphine gas but the crew member was relocated to another cabin.

The next day, a phosphine gas reading of 2 ppm was measured at the upper deck alleyway. The Master called muster stations and instructed all crew to evacuate their cabins at once. The engine cadet did not appear at muster, so two crew went to his cabin where he was found in a state of partial paralysis. The victim was taken outside for care. A phosphine gas reading of 9 ppm was measured in his cabin, which was next to the cabin of the crew member who had been relocated the previous day.

Over the next hour, the victim’s vital signs deteriorated. A request for radio medical advice was sent and cardio-pulmonary resuscitation was carried out, but the crew were unable to revive the victim. His body was brought ashore at a port of refuge two days later.

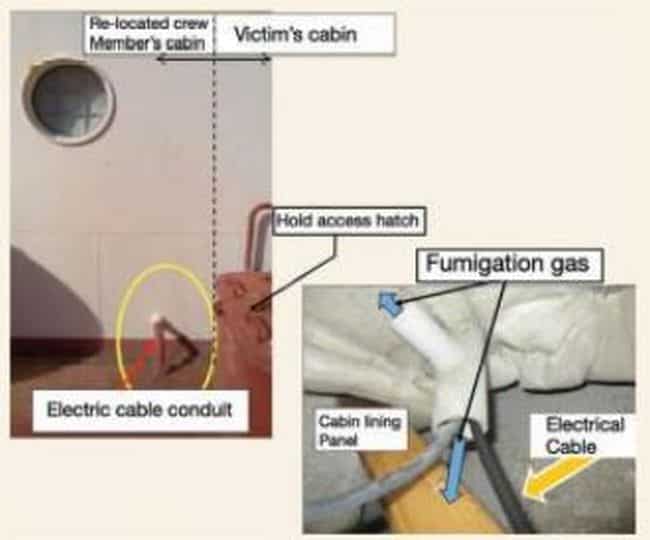

The official investigation found, among other things, that a permanent access light for the aft access ladder of No. 5 cargo hold had been installed during construction. A conduit was used to run the electric cable between the accommodation and No. 5 cargo hold. The conduit ends were not sealed, contrary to best practices and classification rules. This defect allowed the phosphine gas to infiltrate the accommodation area and enter the crew cabins.

Lessons learned

- As in the previous report, MARS 202209, the suitability of a vessel for fumigation is a critical factor and could mean the difference between life or death. In this case, a ‘man-made’ defect rendered the vessel unsuitable for fumigation.

- Deadly fumigation gases can take several days to infiltrate accommodation areas, even when a clear passage exists, as in this case. Continuous or very frequent testing is the best defence against this danger.

Reference: nautinst.org

Do you have info to share with us ? Suggest a correction

About Author

Marine Insight News Network is a premier source for up-to-date, comprehensive, and insightful coverage of the maritime industry. Dedicated to offering the latest news, trends, and analyses in shipping, marine technology, regulations, and global maritime affairs, Marine Insight News Network prides itself on delivering accurate, engaging, and relevant information.

About Author

Marine Insight News Network is a premier source for up-to-date, comprehensive, and insightful coverage of the maritime industry. Dedicated to offering the latest news, trends, and analyses in shipping, marine technology, regulations, and global maritime affairs, Marine Insight News Network prides itself on delivering accurate, engaging, and relevant information.

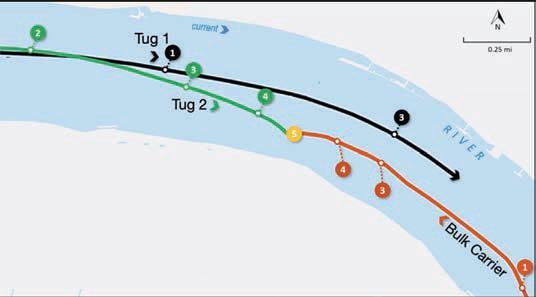

- Real Life Incident: Vessel Collision in Good Visibility

- Real Life Incident: Severe Injury To Deck Crew While Leaving Berth

- Real Life Incident: Departure Damage in Very Restricted Waterway

- Real Life Incident: Low Situational Awareness Has High Impact Consequence

- Real Life Incident: Fouled Anchor in a Designated Anchorage

- Real Life Incident: Fire On Barge Carrying Scrap Metal Causes $7 Million Worth Of Damage

Latest Case studies Articles You Would Like:

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.