Real Life Accident: Pointing The Finger At Careless Work Practices

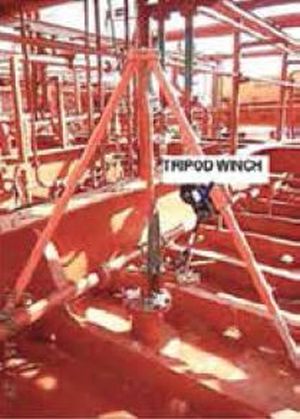

Three crew were in the process of overhauling a tank cleaning machine for one of the cargo tanks. At the end of the overhaul the cleaning machine was being repositioned in the hold using a tripod winch.

As the inlet housing of the cleaning machine was being lowered in a controlled manner using the tripod winch, one of the crew inserted his fingers under the flange to retain the O ring in its grove as it kept slipping out of position.

The inlet housing was approximately five cm off its final resting place when the winch, clamped on tripod leg, suddenly and unexpectedly moved. This caused the inlet housing flange to drop on the middle finger of the crewman’s right hand causing deep lacerations.

Report findings:

- Inadequate engineering; the clamp holding the winch slipped on the tripod leg causing the suspended load to trap the crew’s finger.

- Retaining the ‘O’ ring in the groove using fingers is incorrect practice. In such cases, it is good practice to use Loctite (or similar) to maintain the correct position of the ‘O’ ring in the groove of the flange.

- Lack of thorough risk assessment prior to undertaking the job.

Reference: nautinst.org

Do you have info to share with us ? Suggest a correction

- Real Life Incident: Vessel Collision in Good Visibility

- Real Life Incident: Severe Injury To Deck Crew While Leaving Berth

- Real Life Incident: Departure Damage in Very Restricted Waterway

- Real Life Incident: Low Situational Awareness Has High Impact Consequence

- Real Life Incident: Fouled Anchor in a Designated Anchorage

- Real Life Incident: Fire On Barge Carrying Scrap Metal Causes $7 Million Worth Of Damage

Latest Case studies Articles You Would Like:

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.