Real Life Accident: Avoiding Boiler Blowups

Boiler explosions and defects, although not common, do happen from time to time and have the potential for very serious consequences.

For example, testing of the boiler water should be a scheduled maintenance task and samples forwarded to specialists. Their feedback and recommendations should be carefully considered and followed up. The energy released in a boiler explosion is tremendous and poor boiler treatment or boiler repairs can be catastrophic. When repairs to the boilers are required, always use specialists as improvised repairs by a non-specialist are rarely to specifications.

For example, welding gives high heat input; too much heat will change the material properties of the steel (furnace, steam drums, tubes). Never attempt to gouge out and re-weld cracks in boilers. Heat damaged material, including welds, should be repaired by inserts. The size of inserts should be sufficient to keep the heat affected zones of the individual welds apart. Again, this speaks to hiring boiler repair specialists and involving your classification society.

Lessons learned

- Ensure the engine crew maintain the boiler as per manufacturer’s specifications.

- A clean, well maintained boiler has little or no fouling. As fouling increases, so does heat transfer and so boiler degradation.

- Always use specialists for steel repairs to boilers.

- Ensure class approval for any repairs to boilers.

Reference: nautinst.org

Do you have info to share with us ? Suggest a correction

- Real Life Incident: Vessel Collision in Good Visibility

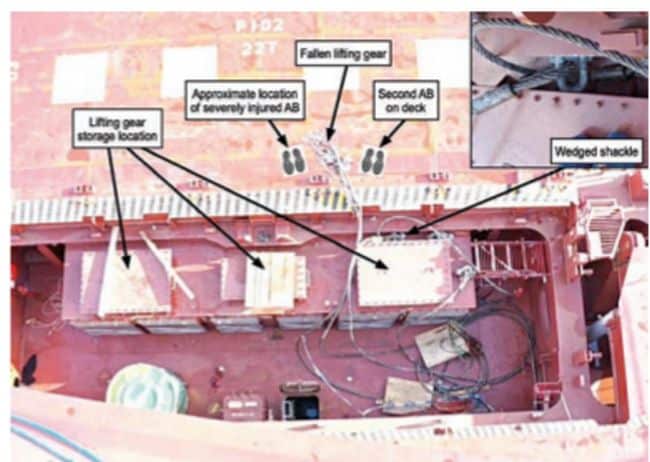

- Real Life Incident: Severe Injury To Deck Crew While Leaving Berth

- Real Life Incident: Departure Damage in Very Restricted Waterway

- Real Life Incident: Low Situational Awareness Has High Impact Consequence

- Real Life Incident: Fouled Anchor in a Designated Anchorage

- Real Life Incident: Fire On Barge Carrying Scrap Metal Causes $7 Million Worth Of Damage

Latest Case studies Articles You Would Like:

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.