Case Study: Soot Blowing Leads To Fire

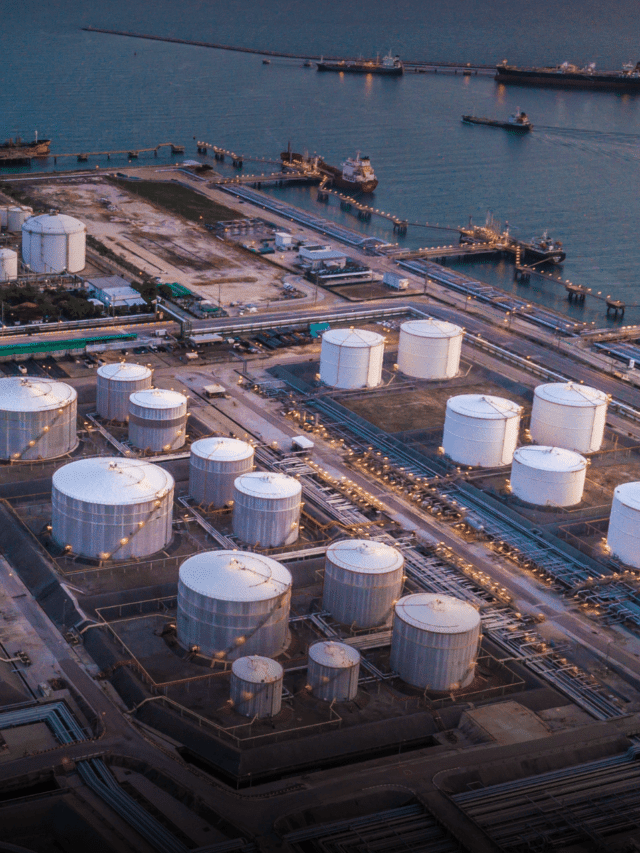

A tanker was underway at sea when two crew members noticed smoke coming from the upper deck alleyway. They alerted the rest of the crew and started investigating the source of the smoke.

They quickly found that the canvas cover of the emergency towing wire aft had caught fire. The emergency response procedures were activated and the fire was quickly extinguished.

The company investigation concluded that the incident was probably caused by a soot particle emitted from the funnel during soot blowing.

Lessons learned

- Soot blowing has associated risks. As such, proper procedures and risk control measures should be implemented.

- The OOW on the bridge should be informed before soot blowing begins. It may be necessary to alter the ship’s course during blowing to help prevent soot deposits and sparks from accumulating on deck.

- Soot blowing must not be carried out when the wind is blowing from the stern.

- During the soot blowing process deck crew should be assigned to monitor the open deck and ensure that sparks and ignited soot are safely controlled.

- Combustible material should not be stored on the open deck. It should always be properly and safely stored in closed, dedicated spaces.

Reference: nautinst.org

Do you have info to share with us ? Suggest a correction

About Author

Marine Insight News Network is a premier source for up-to-date, comprehensive, and insightful coverage of the maritime industry. Dedicated to offering the latest news, trends, and analyses in shipping, marine technology, regulations, and global maritime affairs, Marine Insight News Network prides itself on delivering accurate, engaging, and relevant information.

About Author

Marine Insight News Network is a premier source for up-to-date, comprehensive, and insightful coverage of the maritime industry. Dedicated to offering the latest news, trends, and analyses in shipping, marine technology, regulations, and global maritime affairs, Marine Insight News Network prides itself on delivering accurate, engaging, and relevant information.

- Real Life Incident: Vessel Collision in Good Visibility

- Real Life Incident: Severe Injury To Deck Crew While Leaving Berth

- Real Life Incident: Departure Damage in Very Restricted Waterway

- Real Life Incident: Low Situational Awareness Has High Impact Consequence

- Real Life Incident: Fouled Anchor in a Designated Anchorage

- Real Life Incident: Fire On Barge Carrying Scrap Metal Causes $7 Million Worth Of Damage

Latest Case studies Articles You Would Like:

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Web Stories