The Saipem 7000: One of the Biggest Cranes in the World

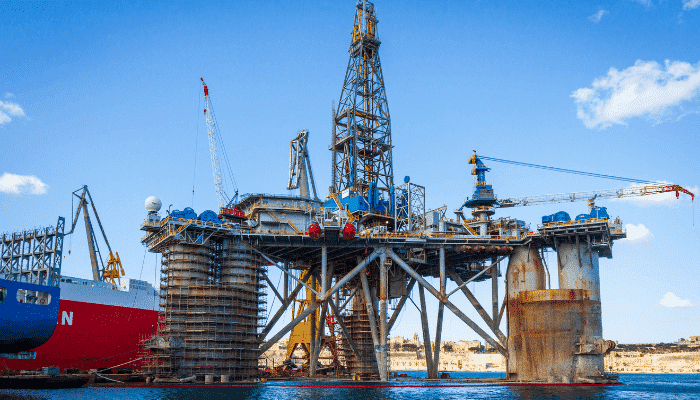

Owned and operated by Saipem, the Italian oil and gas industry contractor, Saipem 7000 is the second biggest crane vessel in the world after SSCV Thialf of Heerema Marine Contractors. Equipped with two cranes, each with a load lifting capacity of 7,000 tonnes each, the Saipem 7000 is capable of lifting 14000 tonnes at 42 meters crane radius. Saipem 7000 retains the world lifting records though Thialf remains the world’s largest crane vessel because of the latter’s less lift radius. Thialf can only lift 14200 to 31.2 meters. Put into operation in the year 1988, by its original owner Micoperi as a multipurpose offshore oil platform installation vessel, the Saipem 7000 has provided excellence par services to its owners during nearly a quarter of a century. A crane ship completely unlike any, the Saipem 7000 is truly a caster-class to wonder at and coupled with its efficiency, the vessel becomes a marine engineering worth admiring.

Design and Construction

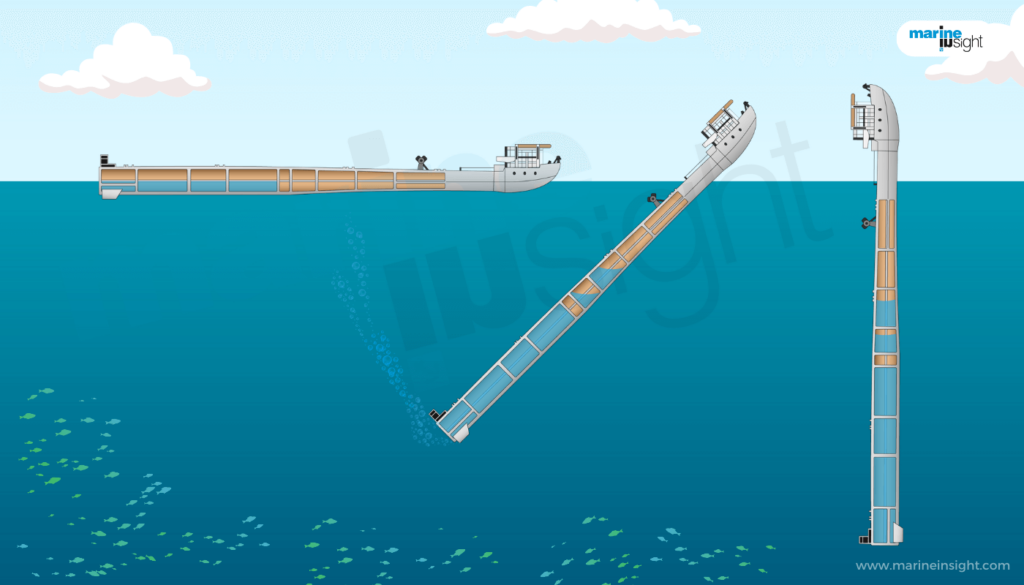

The semi-submersible crane vessel was built during an era when the crane ships used to be relatively smaller and had relatively low load hoisting capacity. In the mid-80’s, Micoperi developed the idea of a multipurpose vessel in order to install very large oil production platform decks and its supporting structures using large fully revolving cranes. The design also included accommodation and workshop facilities for the crew involved in the installation and other works related to the offshore oil platforms. Saipem 7000, originally named as Micoperi 7000, was constructed with the primary purpose to ensure that the offshore constructional activities were completed faster and with better efficiency.

The design of the vessel was completed in 1984 by Gusto Engineering and the construction of the vessel was carried out by the Italian shipbuilders Fincantieri in their shipbuilding yard located in the province of Monfalcone between 1985 and 1987. Saipem 7000 was constructed wholly at a single time but as two separate parts which were later assembled to form one ship in its entirety. After constructing in two halves in a long dry dock, the hull mating of the vessel was completed in early 1987. Following this, the sea trials of the Saipem 7000 was started in September before delivering the vessel to Micoperi in December same year. The vessel was built at an estimated cost of about US$ 400 million and according to the vessel’s owners, the utility of the vessel would far exceed its construction costs making it a very profitable investment.

Saipem acquired the semi-submersible crane vessel in 1991 as Micoperi struggled financially in the early 90’s and forced to sell a number of their major assets, including the Micoperi 7000. The Italian contractor renamed the vessel as Saipem 7000 but retained the crew of the vessel and the shore-based engineering support.

Specifications of Saipem 7000

The 198 metres-long floating crane Saipem 7000 has a breadth of 87 metres, a depth of 43.5 metres and a transit draft of 10.5 metres. Powered by eight 12-cylinder 8400 hp diesel engines, each offering a power supply of about 8,400 horsepower, Saipem 7000 is capable of cruising at a speed of 9.5 knots. The vessel is also equipped with 12 thrusters- six on each hull- for exact manoeuvring and two ballast systems with a total capacity of more than 100,000 cu. m. for better operational ease. The mooring system of the vessel features 16 anchor lines- four at each corner- that consists of 3350 m of 96 mm wire rope, 50 m of 92 mm chain and a 40-tonne Norshore Mark 3 anchor. In addition, Saipem 7000 features a grade III dynamic positioning system as per the Det Norske Veritas (DNV) stipulations.

The vessel features two NOV Lifting and Handling AmClyde model S7000 fully revolving cranes, which have a 140-metre-long boom each fitted with 4 hooks. As mentioned earlier, both the cranes are capable of lifting up to 7,000 tonnes at 40 metre lift radius using the main hook. The cranes are powered by 15,600 hp engines and use 48 miles of wire rope of various diameters. The vessel also has two state-of-the-art remote operated vehicles (ROVs) to support the underwater works required. With all its state-of-the-art facilities, Saipem 7000 is capable of handling the entire work scope of offshore construction developments that include pipe laying in water depths up to 2,000 metres and heavy lift operations over 14,000 tonnes.

With a free deck area of 9,000 sq. m., the vessel has a helipad to dock two Chinook copters of BV 234 LR Class. Moreover, Saipem 7000 can house around 800 people during the construction work with the facilities including 30 triple cabins, 335 double cabins, 35 singles and 5 suites. Moreover, the accommodation facilities include a large galley, a hospital, cinema, mess rooms and lounges.

Service History

After beginning operation in the year 1988 under Micoperi, the vessel’s first work was for the Brazilian state oil company Petrobras. For Petrobras, the vessel carried out the installation of 7 platforms in the Campos Basin in Brazil. Following this, Micoperi 7000 was sent to the Gulf of Mexico for the installation of Jolliet Template for Conoco. In the next year, the vessel was reached in the North Sea in order to carry out a number of projects in the Norwegian sector. Those projects included the Gyda Platform for BP, the Veslefrikk platform for Statoil and the Togi Template for Norsk Hydro. In the early 90’s, the vessel was involved in the construction of the Mossgas FA platform off the south coast of South Africa.

Under the ownership of Saipem, during 90’s, the vessel continued to support oil platform installation and related projects in the North Sea, Gulf of Mexico, off the Canadian east coast and the west coast of Africa etc. Recent projects that Saipem 7000 carried out include heavy lift works, both for installation and modification to existing platforms, in the North Sea and the Gulf of Mexico. The vessel was also part of projects such as 4 J-Lay pipe projects Diana, Blue Stream, Ormen Lange and Medgaz, Frigg Field decommissioning and also the removal of the Ekofisk 2/4 S jacket and the Ekofisk 2/4 G bridge. Recently, Saipem was in news after removing the first structure from decommissioned BP’s Miller platform in the UK central North Sea.

The Saipem 7000 broke a world record in July 2010 by lifting the BP Valhall Production topside of around 11,600 tonnes on Dynamic Positioning. The previous record was set by the vessel for the Sabratha deck in the Mediterranean Sea, lifting 12,150 tonnes, but performed on the vessel’s anchoring system. In addition, the vessel made headlines after laying the 24″ pipeline up to the record depth of 2,150 meters in the Black Sea for the Blue Stream project between Russia and Turkey. However, this record was broken by the Balder which laid a pipeline in 2,200 meters of water in 2005.

The vessel refits and accidents

The end of 90’s, the vessel had undergone a refit to improve its positioning and power systems and also to add a J-lay system. During this enhancement programme, the vessel’s power system was upgraded to deliver up to 70,000 kW with the help of 12 diesel generators. The vessel also saw the addition of two 5,500 kW retractable azimuthing thrusters and new DP system control computers. In addition, the hull, deck and deck structures of Saipem 7000 were modified in order to to accept the Gusto designed J-lay tower and related equipment. Recently in 2013, the vessel completed a large-scale retrofit that saw the replacement of several key systems including automation, Dynamic Positioning, Thruster control, Ballast control and Integrated Bridge System, among others.

In September 2008, during the construction of an undersea gas platform between Spain and Algeria, three workers were killed and four were badly injured after a crane on the Saipem 7000 platform suffered a mechanical failure. Majority of the workers affected were the employees of Saipem. In August 2007, a Philippine sailor was also died on board the vessel during a lifting operation performed for Statoil at the Tordis field.

Disclaimer: The authors’ views expressed in this article do not necessarily reflect the views of Marine Insight. Data and charts, if used, in the article have been sourced from available information and have not been authenticated by any statutory authority. The author and Marine Insight do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendation on any course of action to be followed by the reader.

The article or images cannot be reproduced, copied, shared or used in any form without the permission of the author and Marine Insight.

References: saipem

Latest Type Of Ships Articles You Would Like:

Do you have info to share with us ? Suggest a correction

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Web Stories