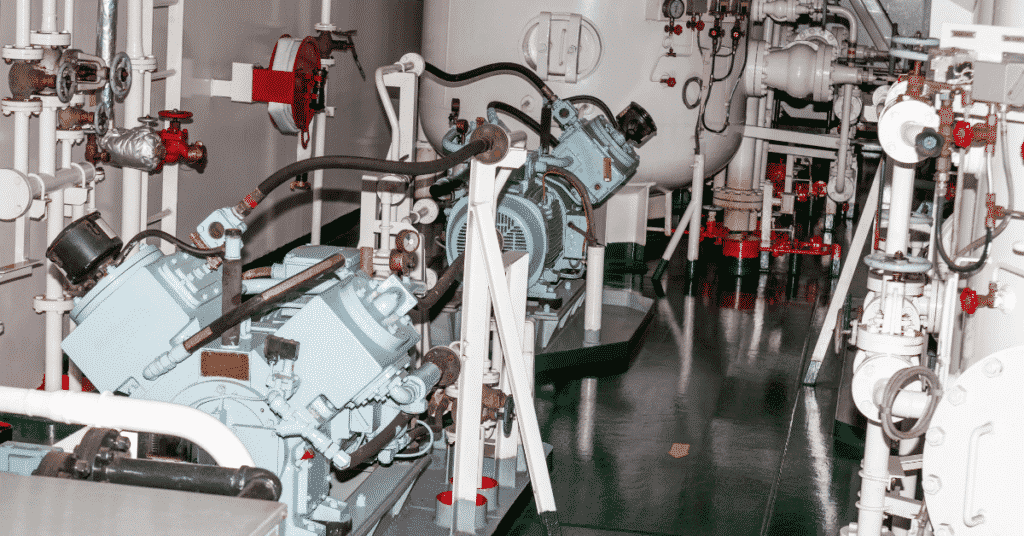

Troubleshooting Air Compressors on a Ship: The Ultimate Guide

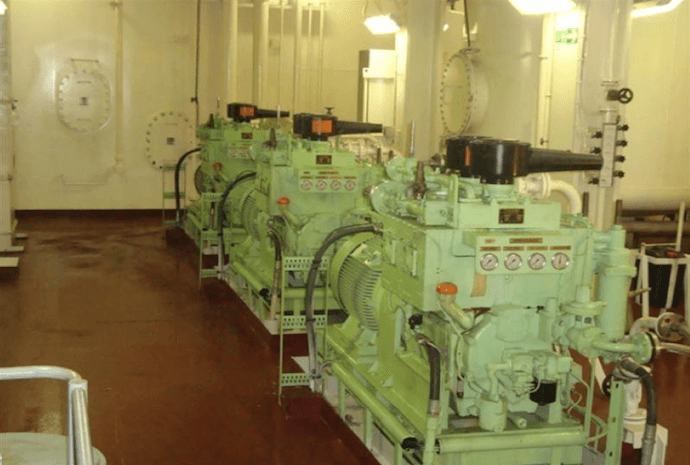

Air compressors on a ship require special attention and care for their smooth running. It is only through routine maintenance and checkups that you can expect smooth and efficient running of the compressors.

However, compressor is a peculiar equipment which tends to get some or the other problem while working. In this article, we will go through each and every problem that can arise in an air compressor and also enumerate ways to troubleshoot that problem.

This is the ultimate guide for troubleshooting air compressors on a ship

Lube Oil Pressure Low

The following can be the reasons for lube oil pressure low in the air compressor:

- Faulty pressure gauge.

- Cock to pressure gauge in closed position.

- Low oil level in the sump.

- Leakage in supply pipe.

- Suction filter is choked.

- Oil grade in the crank case is not compatible.

- Attached Lube oil gear pump is faulty.

- Worn out Bearing, clearance is more.

2) Abnormal noise during operation

If you get any abnormal noise during operation, the following can be the reasons:

- Loose foundation bolts.

- Worn out bearings, clearance is high.

- Imbalance crankshaft resulting in high-end play.

- Valve plate broken or faulty.

- Relief valve lifting below setting pressure.

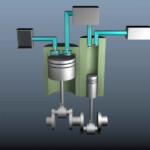

- Bumping clearance is less.

- Piston worn-out, broken piston ring.

Vibration in the machinery:

In case of vibrations, the following reasons are to be considered and checked.

- Foundation bolts are loose.

- Discharge pressure high, faulty discharge valve plates.

- Liner and piston worn out.

- Small bumping clearance.

4)Cooling water temperature is high

Cooling water temperature can go high because of the following reasons:

- Inlet or outlet valve for cooling water is closed.

- Inter-cooler is chocked.

- Cooling water in the expansion tank is low.

- Pipe passage becomes narrow due to scale formation.

- Water-pump belt or gear drive broken.

- ump not working.

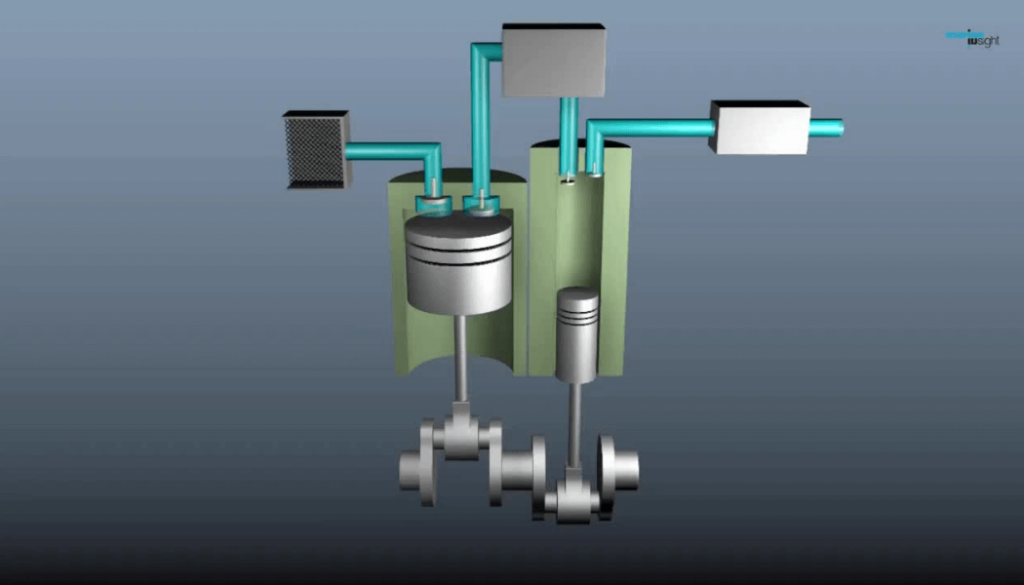

5)First stage discharge pressure high

In case the first stage discharge pressure is high, it must be because of :

- Pressure gauge is faulty.

- Inter-cooler air passage is chocked.

- Second stage suction valve is not closing properly, allowing air to escape from 2nd to 1st stage.

- Discharge valve of first stage is malfunctioning, and remains in closed position.

- Spring of discharge valve is malfunctioning.

6) First stage discharge pressure low

In case the first stage discharge pressure is low, it must be because of:

- Pressure gauge is faulty.

- Suction filter is choked.

- Unloader of first stage is leaking.

- First stage suction valve is not closing properly, resulting in compressed air leakage.

- First stage suction valve is not opening fully, leading to less intake of air.

- Discharge valve is faulty and remains open permanently.

- Relief valve after first stage is leaking.

- Piston ring of first stage is badly worn out, allowing air to pass.

7) Second stage discharge pressure high:

In the case of high discharge pressure in the second stage, the reasons can be:

- Faulty pressure gauge.

- Discharge valve to air bottle is shut.

- Second stage discharge valve plate worn out, and even the spring worn out.

- Valve is stuck in closed position.

- After cooler air passage choked.

- Air bottle is over pressurized.

8 ) Second stage discharge pressure low:

When second stage discharge pressure is low, it could be because of:

- Pressure gauge is faulty.

- Suction valve for second stage is malfunctioning, in open position.

- Suction valve for second stage is not opening fully, and thus less intake of air.

- Discharge valve is faulty and remains open during operation.

- Piston rings of second stage are worn out, leaking out compressed air.

- Relief valve of second stage is leaking.

- Un-loader of second stage is leaking.

9) Relief valve of first stage lifting

If relief valve of the first stage is lifting, it can be because of

- Spring of relief valve is malfunctioning, thus lifting at less pressure.

- Discharge valve of first stage is not opening.

- Intercooler air passage is blocked.

- Suction valve of second stage is in stuck position.

- Water inside the compression chamber due to crack in the jacket and water is leaking inside

10) Relief valve of second stage is lifting

If relief valve of the second stage is lifting, look for the following reasons:

- Relief valve is malfunctioning, lifting at lower than setting pressure.

- Main discharge valve to the air bottle is closed.

- Discharge valve plates and spring are worn out, valve in closed position.

- Blockage in the after cooler air passage.

- Water inside the compression chamber due to crack jacket.

The above-mentioned points are just a brief explanation to the problems of the air compressor tackled on board. However, they serve as a guiding light for finding the right fault in the compressor.

You may also like to read – What is a Bearing Scraper?

Do you have info to share with us ? Suggest a correction

Latest Marine Technology Articles You Would Like:

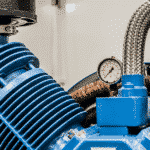

- Compressed Air Line On Ships – A General Overview

- Marine Air Compressor Maintenance – Things You Must Know About

- The Ultimate Guide to Air Compressors on Ships

- What is Clearance Volume or Bumping Clearance in Air Compressors?

- Troubleshooting Air Compressors on a Ship: The Ultimate Guide

- Safety Features and Maintenance Procedure for Air Compressor on a Ship

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Web Stories

About Author

An ardent sailor and a techie, Anish Wankhede has voyaged on a number of ships as a marine engineer officer. He loves multitasking, networking, and troubleshooting. He is the one behind the unique creativity and aesthetics at Marine Insight.

nice

Also it is worth mentioning when there is a high lubrication consumption incident ,what kind of steps/checking to be followed up.

Good day sir, i have a problem with my air compressor tanabe h-264 model. It breakdown because of seizure of piston and cylider liner. We suspect oil starvation that cause the breakdown or malfunction of lubricator. After overhauling the compressor and replacing the lubricator assembly we tested the compressor. During initial run all we observe pressure of 1st stage, 2nd stage, oil and water gage are all normal. Except after a minute of running we observe that there is no oil coming from lubricator going to cylinder for lubrication. And the sight glass has no indication of oil present. We check and clean strainer, replace oil filter and run again. The same problem arise, no oil coming from lubricator even the oil gage in normal pressure. I hope to hear your opinion in these problem to rectify this problem. Your comment will be highly appreciated.

Valuable information…thanks sir..

Thank you for your inputs. We will pass this to our editorial team.

?

Dear sir, What is the procedure for air compressor relief valve testing? Nowadays, this question is asked in coc 3. But can’t find the answer anywhere.

Dear sirs’.we have hatlapa w 220 type (2002 model) piston air compressor.on board. It was overhauled by us and we have faced to,high pressure about 15 bar at first stage conbine valf.It should be 5bar.What was the problem? Please advise us.Many thanks.

Dear all

We have sperre hv2/285a water cooled air compressor on board. After overhauling(new piston, rings, liner,….) there is still air blowing from crankcase

Does anybody know the reason

compressor motor over lode.

sir i have a problem with my tanabe h64 low water cooling pressure and low lube oil pressure

Sir we have sperre air compressor. But 3rd stage lamella valve always became broken. Why this happen?

Dear

On ship we have main air compressor Donghwa-Tanabe air compressor H-74. It is happend breakdown because of seizure of piston and cyl liner. We aspect that was problem in lubricator. Liner and piston with piston rings are replaced, also we replace new lubricator. After starting it was everything ok. We observe that is coming very small amount of oil from lubricator. Also we compare with another comppresors, similar quantity of is coming from another compressor. Breakdown is happend after 1200 RH.

After overhaul compressor was running 120 RH and we detect changing in oil… we remove valves from 2nd stage and it was detected same problem like before. Again seizure on piston and liner. Now we need some sugestion what to do and what to check… Look like we dont have problem with lubricating because we put new lubricator and when we compare with another compressor we dont see difference…

Thanks in advance