Important Things To Check In Ship’s Engine Bedplate

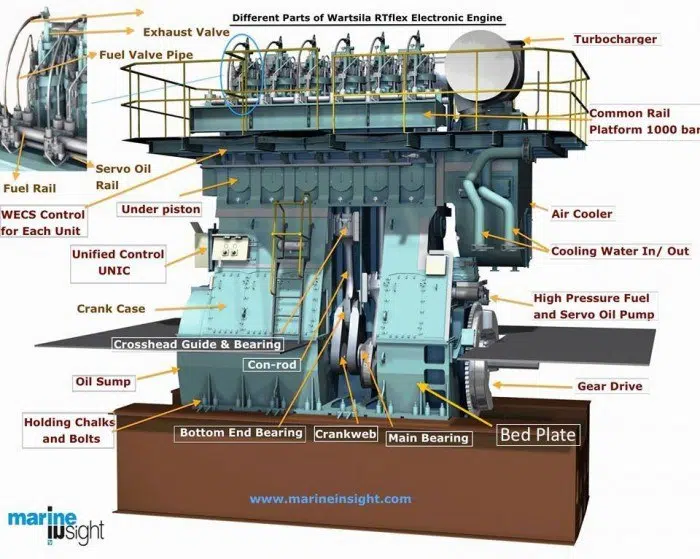

A bedplate is the lowermost portion of a marine engine (2 and 4 stroke), which supports the engine structure and is also one of the most loaded constructional parts of the engine. For large engines, the bedplate is fabricated in parts with flat bottom type construction having high surface finish. The bedplate is later arranged together during installation in large engines, whereas for smaller engines the bedplate is fully casted.

For large bedplates the material used can be cast or prefabricated steel or a mixture of both. The important requirement for large engine bedplate is to use material with low carbon steel with maximum carbon content of 0.23%. For small bedplate, cast iron with internal vibration damping characteristics is used, which reduces the frequency of cracks in the bedplate. The main components of any bedplate are longitudinal and cross girders.

The important functions of bedplate are:

- To support the static load of stationary engine frame and blocks

- To support the dynamic load of the running gear

- To support the crankshaft and hold it in perfect alignment

- To distribute the static and dynamic load generated by running engine onto the ship structure

- To collect the crankcase lube oil and transfer it to the sump tank from where the lube oil pump can take suction

- To fasten the engine to the tank top transmitting propeller thrust to the hull structure

- To contribute to the hull strength of the ship at engine room bottom structure

It is important to keep a regular check on the bedplate as it’s the foundation of the marine engine. The inspection of bedplate is also included in the planned management system of engine.

Following checks to be carried on the bedplate during inspection:

Cracks: Cracks is the most common problem that occurs on the bedplate structure. Following areas to be carefully checked for cracks:

- Welding portion which joins the transverse girders to the longitudinal girders

- Under the bearing pockets where cracks can emerge to be radial or follow the line of the pocket which holds the bearing

- Radially at tie bolt and frame bolt holes

- Around lightening holes provided in the bedplates and girders

- At the base of main bearing keeps

Faulty welding: It is to be checked on newly delivered engine or if any welding repairs are carried out in the recent past

Faulty casting – It is to be checked on newly delivered engine with casting construction

Corrosion: As the bedplate is the bottom structure fitted in the bilge section of the engine room, it comes in contact with various fluids such as oil, water etc. and therefore is prone to corrosion. A close check should be made for identifying corrosion.

Loose Frames: The bedplate is held together with A frame and entablature of the engine by means of tie rod. Check the tie rod is tightened and there is no loose portion between the frame and bedplate.

Faulty Holding Down Bolts: The holding down bolts keeps the bedplate in position with the bottom structure of the ship. Check for loose holding down bolts and tighten as per the manual if found loose. Also, check for shearing and fretting on the holding down bolts.

Oil leakages: The bedplate is also responsible to collect the lube oil and transfer it to engine sump. Check for any oil leakage from the bedplate or the joint between the bedplate and the frame.

Ship’s engineers are responsible to ensure that marine engine bedplate is inspected at regular intervals of time and all faults are identified and repaired at the earliest. Failing to do so will result in heavy vibrations, misalignment of crankshaft, and reduction in engine efficiency and failure of engine components.

Over to you..

Do you know about any other important points to be noted while checking engine room bed plate?

Let’s know in the comments below.

Do you have info to share with us ? Suggest a correction

About Author

An ardent sailor and a techie, Anish Wankhede has voyaged on a number of ships as a marine engineer officer. He loves multitasking, networking, and troubleshooting. He is the one behind the unique creativity and aesthetics at Marine Insight.

Latest Marine Technology Articles You Would Like:

- 10 Harmful Effects Of Impure Air On Ship’s Machinery

- 10 Important Things to Check While Starting Fuel Oil Purifier on Ships

- 10 Noteworthy LNG-Powered Vessels

- 10 Points for Efficient Turbocharger Operation On Ships

- 10 Practical Tips to Handle Engine Room Pumps

- 10 Precautions to Take Before Operating Controllable Pitch Propeller (CPP) on Ships

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Very educative!

nic

Good

nice

Super

Nic to learn n I want to more about

Good note for marine students

Very informative indeed. The only thing that came to mind would be to keep a log of holding down bolts that are tightened each time. Marking them by numbers on a diagram sheet. Think it would be a handy log going forward to have a history. There maybe a developing pattern which may come up.

Thanks!

Big thanks to you guys!

Simply the best answer for class 2&1 coc exam

What inspections would you carry out on the bedplate section of a large slow speed engine, during a routine crankcase inspection.

For crankcase inspection , please check the following article:

https://www.marineinsight.com/main-engine/everything-you-ever-wanted-to-know-about-crankcase-inspection-on-a-ship/

l will thank you very much for educating me ,well done .