How COMPAC Stern Tube Bearing System Can Prevent Oil Pollution?

The rotation of a ship’s propeller is responsible for the ahead or astern movement of the vessel. The propeller is connected to the Marine Propulsion engine through intermediate and propeller shaft.

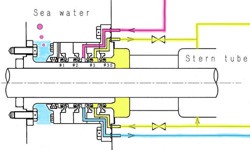

At the aft end of the ship, the propeller shaft has to protrude out of the ship so that it can be connected to the propeller. A stern tube is located at the aft end and the propeller shaft is passed through it in such a manner that sea water does not seep inside and the lubricating oil of the tube does not go outside in the sea.

The Conventional Stern Tube System

The conventional stern tube system normally consists of a stern tube liner, stern tube bearing, and shaft or labyrinth seals. The aft peak bulkhead supports the forward part of the stern tube and other end is supported by the stern framing of the ship.

The propeller shaft passes through the liner and is supported by the stern tube white metal bearings. These bearings are lubricated by lube oil and to prevent leakage of oil out at sea or ingress of water inside the tube, lip seals are attached at forward and aft part of the tube.

Thordon COMPAC Bearing System

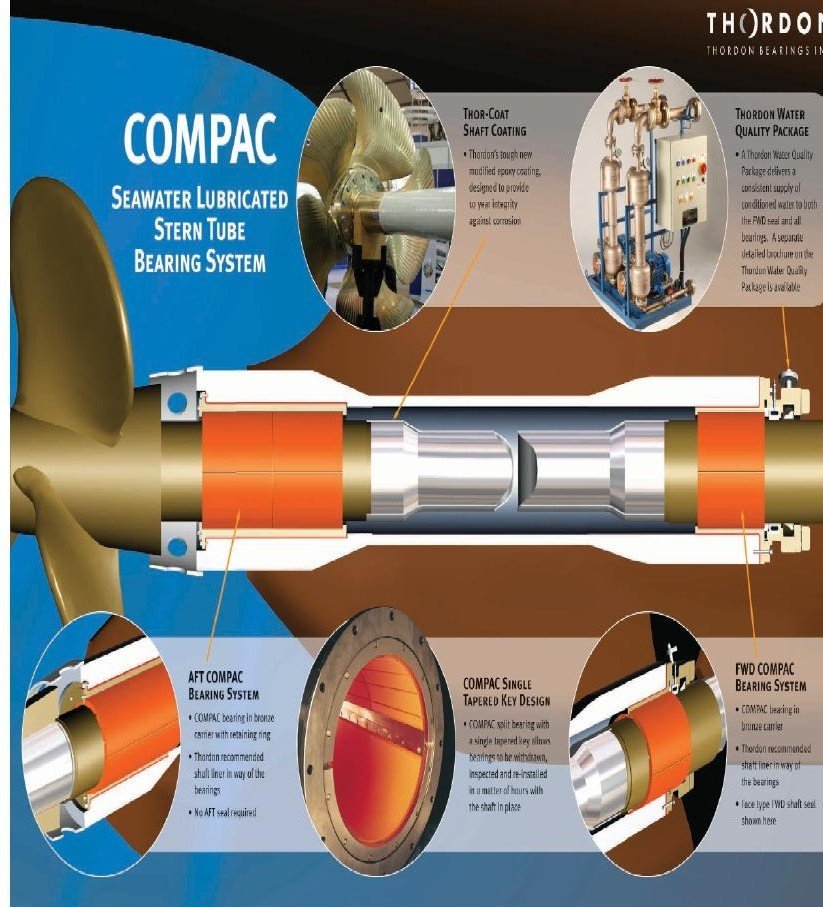

The Thordon bearing system uses sea water for lubrication of the propeller shaft and bearing.

The main components of this system are:

Thordon Bearing: It is a non metallic bearing made from elastomeric polymer alloys, which enables it to get lubricated by sea water so that there is no friction between the rotating propeller shaft and bearings.

Thor Coated Shaft: The propellers shaft is applied with an anti corrosive paint coating known as Thor Coating which enables it to work with sea water which is highly corrosive in nature.

Shaft Seal: In this system only one forward seal is required to stop water ingress inside the ship and it is seawater lubricated.

Thordon Water Quality Package: To ensure continuous and sediment free water supply to the bearings and seal, it is passed through the water quality package system which can be connected to the ship’s automation so that it can also run on UMS mode.

Advantage of Thordon COMPAC system

- It eliminates the use of Stern tube lube oil hence no chances of oil pollution

- There is no Aft seal hence system and maintenance cost reduces

- No need of lube oil storage tank

- It eliminates installation of lube oil pumping system

- The maintenance period of such bearing is minimum 10 years hence lower in service cost

You may also like to read-The Cutting Edge Emergency Propulsion System by Marinevest

References:

www.thordonbearings.com

Do you have info to share with us ? Suggest a correction

About Author

An ardent sailor and a techie, Anish Wankhede has voyaged on a number of ships as a marine engineer officer. He loves multitasking, networking, and troubleshooting. He is the one behind the unique creativity and aesthetics at Marine Insight.

Latest Marine Technology Articles You Would Like:

- 10 Harmful Effects Of Impure Air On Ship’s Machinery

- 10 Important Things to Check While Starting Fuel Oil Purifier on Ships

- 10 Noteworthy LNG-Powered Vessels

- 10 Points for Efficient Turbocharger Operation On Ships

- 10 Practical Tips to Handle Engine Room Pumps

- 10 Precautions to Take Before Operating Controllable Pitch Propeller (CPP) on Ships

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Web Stories