Procedure for D’carb of Ship’s Generator

Generator is one of the prime machinery on board a ship. Ship’s generator supplies power to all other machines and acts like the lifeline of the ship. Like other machinery, generator’s on board routine maintenance is also done by the engineers. One of the important procedures of generator maintenance is d’carb, which is carried out by qualified engineers within the time limit set by the makers and technical department.

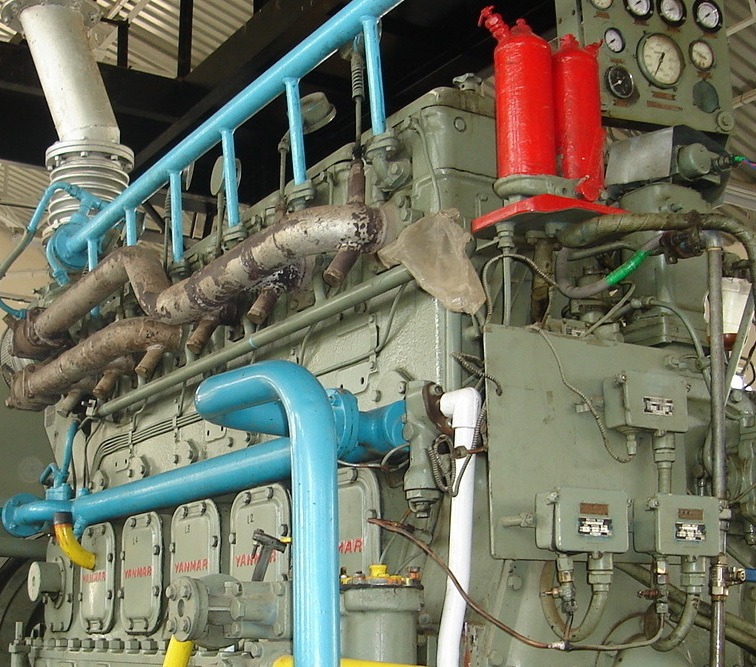

D’carb or de-carbonisation of generator not only means cleaning and removing carbon from parts and spaces involved in combustion of fuel but also includes checking, overhauling and renewal of parts involved in power transmission like connecting rods, con-rod bearings, main bearings etc.

Before d’carb of any of the generators onboard ship, preparation has to be done by management and operational level engineers, and the management level engineers will decide in consent with the office ashore, whether to proceed with the process or not.

Following preparations and checks are to be done before doing d’carb of auxiliary generator onboard vessel:

General Preparations

- Make sure that other generators are available for taking up the load of the ship at all times, in case one or more generators are lined up for d’carb.

- The d’carb of the generator should be planned with such time interval so that during d’carb operation, if any one of the running generator has a breakdown, other generators or means must be available to propel the ship.

- Make sure all the special tools of auxiliary generator are available onboard and are in sound condition.

- Check with the engine stores that all the spares that are required for d’carb are available.

- Raise the requisition for all spare parts required for the d’carb operation.

Before D’carb

- Brief discussion with the team about the procedure as per the manuals is to be done.

- Isolate the given generator from the main switch board and auto start panel.

- Close all the systems attached with the generator like sea water system, fuel oil system, air system, lube oil system etc.

- Inform every one by putting placards and posters of “MEN AT WORK” and “DO NOT START” etc.

- Have a look on the previous d’carb report and fill the pre d’carb checklist.

- If the d’carb includes crank shaft and bearings, record crank shaft deflection prior to the start of the same.

- Tool box meeting to be carried out and risk assessment form to be filled and signed by all the personnel involved in the operation.

During d’carb

- Safety should be the primary concern and personal protective equipment should be donned by all individuals.

- Make sure all the tools, hydraulic jack and lifting devices are placed at safe position before the work begins.

- All the removed parts should be kept in a secured place and in sequential manners.

- Cleaning, checking and measuring should be done and worn out parts are to be replaced as directed by the manual.

- Lifting of all the heavy parts by crane or chain block should be supervised by experienced engineers.

- Care should be taken not to drop any small parts, nut-bolts, tools etc. inside the jacket passage or in the crankcase.

- Clearances and other measurements are should be recorded.

- All the parts should be fitted back under supervision of senior engineer.

After D’carb

- Crank shaft deflection should be taken and recorded.

- Crank case oil should be removed and sump be cleaned.

- Crank case inspection should be done so that nothing is left inside.

- Make sure all the parts are fitted and tightened as per the manual.

- All the isolated systems are put back into operation one by one, starting from the fresh water system. Leaks should be checked thoroughly.

- Fresh oil should be taken and lube oil system should be put back in use followed by fuel oil system.

- Turning gear should be rotated by tommy bar to ensure free movement of crank shaft.

Get the Best Hand on Experience ebook on Generator D’carb

Do you have info to share with us ? Suggest a correction

About Author

An ardent sailor and a techie, Anish Wankhede has voyaged on a number of ships as a marine engineer officer. He loves multitasking, networking, and troubleshooting. He is the one behind the unique creativity and aesthetics at Marine Insight.

Latest Marine Technology Articles You Would Like:

- 10 Situations When Ship’s Generator Must be Stopped Immediately

- 10 Important Tests for Major Overhauling of Ship’s Generator

- 8 Important Points To Note For Maintenance Of Emergency Generators On Ship

- Understanding Different Operational Modes Of Shaft Generator On Ships

- Ways of starting and testing emergency generator

- What’s The Criteria For Reuse or Replacement of Auxiliary Engine Connecting Rod On Ships?

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.