Choosing A Marine Boiler While Designing A Ship

Marine boilers used in ships today are mostly for auxiliary purposes in vessels that run on marine diesel engines or diesel-electric propulsion.

In the case of ships using steam turbines (mostly found in high-speed vessels used by navies), boilers are a part of the main propulsion system. However, in this article, we will focus on auxiliary boilers, i.e. boilers used for running auxiliary systems in a ship.

To look at this from a ship designer’s point of view, he/she should be able to choose the right kind of boiler for a particular ship depending on the requirement for that particular project.

The process is pretty much an application of first principles but in a somewhat different way.

To rate a boiler, one first needs to correctly estimate the steam output required from a boiler for the ship being designed. For this, the three main requirements are:

Requirement 1 – Steam consumption required to compensate heat losses in tanks.

Requirement 2 – Steam consumption required to raise the temperature of fuel oil in tanks.

Requirement 3 – Steam consumption required for other services.

We will discuss each of the requirements, and once done, we will see how the obtained data is used to estimate the capacity of the boiler.

Requirement 1- Steam consumption required to compensate heat losses in tanks:

Most ships run by diesel engines have fuel oil tanks that are used to store Heavy Fuel Oil (HFO). Since the viscosity of HFO is very high, stored HFO is almost as dense as tar, and its high viscosity makes it unable to flow.

But in order to transfer the stored HFO to the settling tanks and then the HFO service tank, the viscosity needs to be maintained at a level corresponding to which easy flow is possible. For this, HFO storage tanks are equipped with heating coils to maintain the fuel at a certain temperature.

The heating fluid in the heating coils is steam that is produced in the auxiliary boiler.

First, each HFO storage tank is located in the general arrangement drawing, and the surrounding space adjacent to each tank bulkhead is noted. Depending on the surrounding of each tank bulkhead (Engine Room, Void, Ballast Water Tank, Sludge Tank, etc.) the ambient temperature is fixed for heat transfer through each bulkhead of the tank in analysis.

The amount of steam flow rate required to maintain the temperature of the fuel in each such tank is calculated using the following steps:

Heat loss from tank bulkhead

Q1 = U A (T2 – T1)

Where

Qb = heat loss from bulkhead (W)

U = overall heat transfer co-efficient (W/m2 0C)

A = Area of tank bulkhead under consideration (m2)

T2 = Temperature of the tank to be maintained (0C)

T1 = Temperature of the adjacent medium of the bulkhead considered (0C)

Heat loss from tank Qt = Sum of heat loss from all the six bulkheads of the tank

Q1 = sum of heat loss from all the tanks

As we know the heat transfer rate, the mass flow rate of steam can be calculated using the following formula :

ms = Q1 / ∆h

Where,

ms = mass flow rate of steam (kg/s)

Q1 = calculated heat transfer (kW)

∆h = enthalpy drop of the steam (kJ/kg)

Requirement 2- Steam consumption required to raise the temperature of fuel oil in tanks:

Not only is steam required to compensate for the heat losses from fuel oil tanks, but steam is also used to heat the fuel oil to the required temperature before being used in the engine.

For this, the time (t) in hours, required to heat up the oil in each type of tank is generally considered as follows:

∆T/t

- For Storage Tank – 0.2 DEG C/HR RISE IN TEMP.

- Service and Settling tank – 4 DEG C/HR RISE IN TEMP.

- All other Tanks – 1 DEG C/HR RISE IN TEMP.

This calculation includes two steps:

- Calculation of heat (Q in watts) required to heat contents of each tank, and summation of all the individual heat requirements to obtain total heat transfer required to raise the temperature of fuel oil in tanks (Q2)

- Utilising the above-obtained heat requirement to find the required mass flow rate of steam for this purpose.

A sample of this calculation is shown below:

The amount of heat required to raise the temperature of fuel oil tanks can be expressed as:

Q2 = m Cp dT / t

Where Q2 = mean heat transfer rate (kW)

m = mass of fuel oil in the tank (kg)

Cp = specific heat capacity of the fuel oil (kJ/kg oC)

dT = Change in temperature of the fuel oil (oC)

t = total time over which the heating process occurs (hours)

As we know the heat transfer rate, the mass flow rate of steam can be calculated using the following formula :

ms = Q2 / ∆h

Where ms = mass flow rate of steam (kg/hr)

Q2 = calculated heat required to raise the temperature (kW)

∆h = enthalpy drop of the steam (kJ/kg)

Requirement 3- Steam consumption required for other services:

Steam is also used in ships to cater to other heating requirements, some of which are listed below:

- Used as a heat exchange medium in Heavy Fuel Oil purifiers, Light Diesel Oil purifiers, and Lube Oil purifiers.

- Steam is used as a heating medium in booster modules.

- To pre-heat the main engine jacket cooling water.

- Used as a heating medium in calorifiers (calorifiers are high-pressure storage units of heated water, which is used in gantry and toilet utilities).

Heat requirements by all such services are calculated individually and added. The obtained heat requirement is termed Q3 (for the purpose of this article only).

Once the heat requirements for the three purposes (mentioned above) are obtained, they are added to obtain the Total Heat Rate and Total Steam Mass Flow Rate Required for the boiler:

Total Heat Rate Required (Q) = Q1 + Q2 + Q3 (kW)

Total Mass Flow Rate Required is calculated from the relation: mS = Q / ∆h (kg/hr)

Where ∆h = enthalpy drop of the steam (kJ/kg)

Now, there are two rating systems to obtain a suitable boiler:

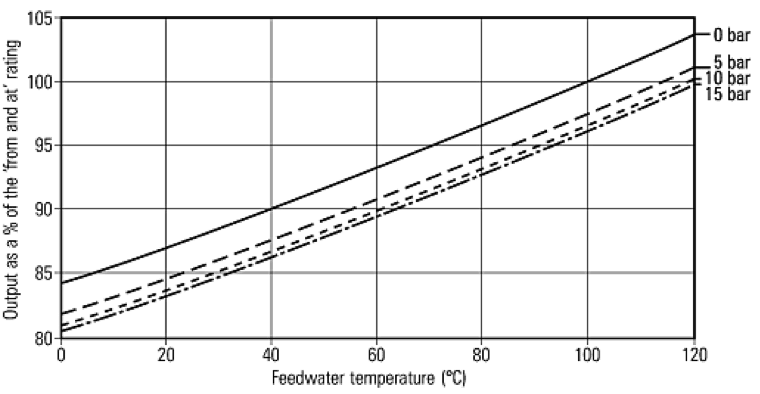

From and At Rating:

In the above graph, the vertical axis corresponds to the steam output as a percentage of the from and at the rating, at different pressures. That is, for example:

At 15 bar,

If feed water temperature is 68 degrees Celsius,

Then the percentage from and at rating from the graph is 90%

So if a boiler has a rated steam output of 2000 kg/hr, the actual steam output of the boiler will be 90% of the rated output, which is 1800 kg/hr.

Now, when a designer chooses a boiler, he/she needs to specify the rated steam output to the boiler manufacturer. The boiler manufacturer, along with the boiler, provides the boiler from and at rating graph for the proposed boiler, and the above calculation is carried out for various boiler pressures and feed water temperatures, to check that the actual steam output is more than the steam flow rate (mS) obtained in the initial design calculations that we have previously discussed.

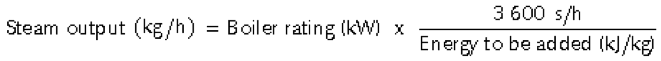

Kilowatt Rating:

While some boiler manufacturers prefer from and at ratings, some others prefer another system called the Kilowatt rating system, which is however just a different way of expressing the same data.

In order to obtain the Actual Steam Flowrate from the kW rating of a boiler, the following relation is used:

In the above expression, the energy to be added refers to the amount of energy added to the boiler by the feed water (which in turn depends on the feedwater temperature).

The designer should make sure that the steam output obtained above is more than the steam flow rate (mS) obtained in the initial design calculations that we have previously discussed.

The above checks are to be carried out at various working pressures of the boiler, and different ranges of feed water temperature, depending on the steam requirement at various sailing conditions. It is to be ensured that the chosen boiler meets the requirements in all such conditions, at different load combinations.

The type of boiler to be used in the ship is also to be chosen by the designer based on the following criteria:

- The functionality of the boiler.

- Space Constraints.

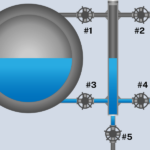

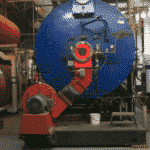

For most auxiliary boilers, shell and tube boilers are used, where the boiler drum holds the water reserve, and fire tubes run along the length of the drum.

The hot gases produced by the burner are carried in the fire tubes that provide more surface area for heat transfer to the water. In most cases, the auxiliary boilers are horizontally oriented in case there are no space constraints, as they prevent pressure fluctuations which is more in the case of vertically oriented boilers.

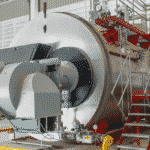

However, for exhaust gas economisers or exhaust gas boilers (These are boilers that do not have a furnace. They have also fired tube boilers, where exhaust gases from the engine are passed through the fire tubes to heat the water in the boiler drum.) vertical configurations are preferable, as it provides less back pressure on the exhaust gas system. Exhaust gas boilers are used when the vessel is on the voyage, and when in port, the auxiliary boiler is used.

Do you have info to share with us ? Suggest a correction

Latest Marine Technology Articles You Would Like:

Related Posts

- Blow-Down Procedure for Marine Boilers

- 6 Practical Tips On Improving Boiler Efficiency for Professional Marine Engineers

- What To Do During Marine Auxiliary Boiler’s Flame Failure or Fuel Pump Tripping?

- Boiler Starting Failure – Troubleshooting

- Understanding Boiler Feed Water Contamination

- Understanding Boiler Refractory And Its Types

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

I really appreciate the work you made Soumya. But i am very curious to know two things about boilers, how long does the boiler must run in order to produce steam daily, this depends on what? and another thing what type of fuel if we use for a boiler that will be very economical as well as efficient. and what is the minimum fuel required for a specific steam generation.

@Samson: Steam generation depends on whether the boiler is cold or hot, i.e. if it is completely stopped (which is cold condition and takes more time to heat up and generate steam) or kept running (which means steam is available). if the boiler is cold, it may take up to 8 to 12 hours to efficiently generate steam without stressing the boiler. In ships, the boiler is usually kept hot at all times and steam supply is controlled using the main steam stop valve on top of the boiler.

In merchant ships, Heavy fuel and Marine gas oil are used as boiler fuel. The amount of fuel usage will depend on the capacity of the boiler.

I am happy because I need this knowledge thanku