Boiler Operation Made Easy : Procedure for Starting and Stopping a Boiler

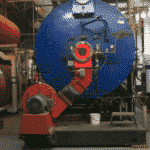

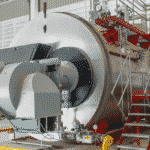

A boiler is one of those machinery that gets the ship going. A boiler is something, though not required continuously in operating a ship, cannot be done away with.

Moreover, it’s dangerous equipment that generates steam at extremely high pressure, and it is for this reason that proper care should be taken while operating it.

In this article, we have brought to you a step-by-step procedure for starting and stopping a boiler on a ship. With this procedure, you can never go wrong, as far as boilers are concerned. Starting and stopping a boiler was never so easy.

Starting a Boiler

It is to note that the following steps may not apply to all types of boilers and each boiler requires some additional steps to be followed as per its system design. However, the basic steps remain the same:

- Ensure that the vent valve on the boiler is open and check there is no pressure in the boiler.

- Check that the steam stop valve is closed.

- Check that all the valves for fuel are open, and let the fuel circulate through the system until it comes to the temperature required by the manufacturer recommendation.

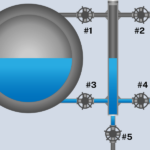

- Check and open the feed water valves to the boiler and fill the water inside the boiler drum to just above the low water level. This is done because it is not possible to start the boiler below the low water level due to safety features that prevent the boiler from starting. Also, the level is not filled much because if filled too much, the water inside the boiler might expand and over pressurize the boiler.

- Start the boiler in automatic mode. The burner fan will start the purging cycle which will remove any gases present in the furnace by forcing it out through the funnel.

- After the pre-set purge time the pilot burner will ignite. The pilot burner consists of two electrodes, through which a large current is passed, via the transformer, producing the spark between the electrodes. The pilot burner is supplied with diesel oil and when the oil passes over, the former ignites.

- The main burner which is supplied by heavy oil catches fire with the help of the pilot burner.

- Check the combustion chamber from the sight glass to ensure the burner has lit and the flame is satisfactory.

- Keep a close eye on the water level as the pressure increases and open the feed water when the level of water inside the gauge glass is stable.

- Close the vent valve after the steam starts coming outside.

- Open the steam stop valve.

- Once the working steam pressure is reached, blow down the gauge glass and float chambers to check for the alarms.

- If the boiler is needed to be stopped for a longer duration for maintenance or opened up for the survey, change the fuel to distillate fuel.

- If a separate heating arrangement for heavy oil is present then there’s is no need to change over to distillate fuel and the oil is kept on circulation mode.

- Stop the boiler automatic cycle.

- Close the steam stop valves.

- Close the boiler feedwater valves.

- When the boiler pressure is just reduced to over atmospheric pressure the vent valve is kept open to prevent vacuum formation inside the boiler.

Disclaimer: The authors’ views expressed in this article do not necessarily reflect the views of Marine Insight. Data and charts, if used, in the article have been sourced from available information and have not been authenticated by any statutory authority. The author and Marine Insight do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendations on any course of action to be followed by the reader.

About Author

Raunek Kantharia is a marine engineer turned maritime writer and entrepreneur. After a brief stint at the sea, he founded Marine Insight in 2010. Apart from managing Marine Insight, he also writes for a number of maritime magazines and websites.

Do you have info to share with us ? Suggest a correction

Latest Marine Technology Articles You Would Like:

Related Posts

- Blow-Down Procedure for Marine Boilers

- 6 Practical Tips On Improving Boiler Efficiency for Professional Marine Engineers

- What To Do During Marine Auxiliary Boiler’s Flame Failure or Fuel Pump Tripping?

- Boiler Starting Failure – Troubleshooting

- Understanding Boiler Feed Water Contamination

- Understanding Boiler Refractory And Its Types

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Ok..great…but is it not true that when we start firing the boiler in automatic mode, it will keep on firing till the boiler reaches the working pressure. And doing so can led to thermal stress & crack. The common practice we used to follow on board my ship was firing the boiler for 10 mins & then stopping it for 30 mins. Then again starting for 10 mins & stopping for 20 mins, & so on until it reaches the working pressure.

and when you fire by auto it will inject great amount of fuel because the boiler need to satisfy immediate the set point cut out… we usually fire by manual to control fuel pressure…

On cold starting of boiler, it is not fired continuously but fired for 10mins and stopped for some time and fired again for 10mins then stopped again.this is to prevent thermal stress build up. Also main steam valve is eased of its seat as the pressure builds up for thermal expansion allowance.

Nice article.

Hi,I want some information on the following,

Kpi’s,

PIMS and POMS

IQMS

If you can just explain the abbreviations and and functions please will be highly appreciated thanks

Eugene

thanks a lot for sharing such type of information on boilrer. i have one on wood fuel based boiler please tell me how to reduce the comsumption of wood for burning to create steam

I appreciate you helping me learn more about boilers. I never knew that they could be so complex. I am glad there are people out there who know the ins and outs of them.