What are Tie Rods and Why Do They Break?

Marine engines are fabricated with different components, which are held and tied together to complete the engine structure with the help of tie rods. As the name suggest, tie rods are long metal rods that are generally found at the periphery of the engine.

Functioning of Tie Rods

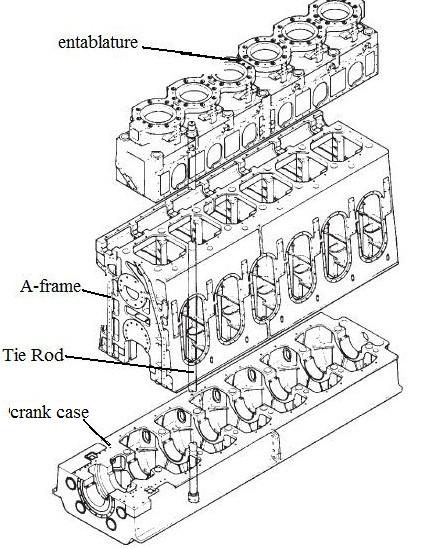

Tie rod is a long strong rod with bolts or tie bolts at both the end. This rod holds the three major engine components i.e. Cylinder block or entablature, “A” frame, and crankcase in compression and transmits the firing load to the bedplate.

The tie rods are fitted through the above mentioned components and are hydraulically tightened so that the whole engine can be held in compression.

Tie rods are placed as close to the centreline of the crankshaft of the engine to minimise the bending movement in the transverse girder.

Effect of loose or broken tie rod

If the tie rod bolts are loosen or broken, then the marine engine will show the following abnormalities:

- It will lead to vibration of the marine engine.

- It will lead to fretting of mating surface of the engine.

- It can lead to crank shaft misalignment.

- Such prolong condition may lead to bearing damage.

- Foundation bolts and chocks may get loose.

- Turbocharger of the engine will be affected as it’s a high speed machine. A little vibration in the machine can damage or misalign the rotor or damage the bearing.

What are the Causes of Tie-Rod Breaking?

- Tie rods are not properly tightened.

- The material and threading of tie rod are under rated and not properly machined.

- Aging of tie rod leading to failure or breakage.

- Tie rods bolts are over tightened by hydraulic pressure crossing its elasticity limit.

- Engine is over loaded or peak pressures of the cylinders are very high.

- Previous fretting of engine mating surface.

- Foundation bolts have become loose or chocks are damaged leading to transmission of vibration in to tie rods.

- Scavenge fire loosen the rods as they pass from the scavenge space and the heat leads to the expansion of the rods.

- Tie rods consist of quenching screws, if they are loose it will lead to heavy vibration leading to loose or crack in the rod.

- If the ship face very heavy weather, the fluctuation in the marine engine load may cause loosening or breakage of the rods.

Reference: marinediesels

Image Credit: Book -Pounder’s Marine Diesel Engines by

Do you have info to share with us ? Suggest a correction

About Author

An ardent sailor and a techie, Anish Wankhede has voyaged on a number of ships as a marine engineer officer. He loves multitasking, networking, and troubleshooting. He is the one behind the unique creativity and aesthetics at Marine Insight.

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Sir,

What is the material of tie rods? How are broken tie rods removed?

Dear Rahul,

Normally High UTS steel is used for construction of Tie rods.

Please refer this link for removing a broken tie rod:https://www.marinediesels.info/repairs/broken_tie_bolt.htm

Sir,if in your sister vessel tie rods are breaking due to heavy weather what will you check in your ship as a chief engineer at sailing?

Sir

Just a query… What r pinching screws n what if a tie rod in mc-c engine breaks at mid length, how to remove the bottom half ?

@ Saurabh ali:

Pinching screws are similar to locking screw which are perpendicular to the tie rod to act against vibration.

For removal procedure, please post the query in our forums as it is a lengthy procedure. – https://forums.marineinsight.com

sir, what are the actions to be taken in case if tie rod breaks while at sea during sailing and what type of threads are there on tie rod?

Sir, material for tie bolt, and please why persistent water accumulate in scavenge space.

We know it’s important for you to get a quick response for your question.

Thus, we created Marine Insight Forums >> https://forums.marineinsight.com

Kindly re-post your question at the forums, after a quick free sign-up and one our experts will reply to you at the earliest.

Register here now >> https://forums.marineinsight.com

Thanks a lot in advance.

Dear sir, In B&W L67GFCA mention after tightening the bolts inspect from the upper face of the bracing stud. But it is very difficult to check that 2mm clearance. Can you help me find a easy method to do it.

Tie rod length is Dependant on the length of stroke of piston .

is this true ?

in your probable causes you havent mentioned engine travelling in the barred speed range !

Sir if tie are broken in manoeuvring condition then what we will do.?

Proceed to berth at lower ship speed and avoid using engine at its max rated power.

Hi Gentlemen.I want to know the clearance between bearing cap and tie bolt.Should be more or less and why?

Thank you

What is pinch bolt? And what is quinching bolt? What is diffrence.tnx

@Sasan: The pinch bolts are sort of clam bolts which holds the tie rod to avoid vibrations.