Real Life Accident: Unsafe Cargo + Unsafe Anchorage = Lost Ship

A bulk carrier was to load a cargo of nickel ore from barges into five holds. During loading, which took approximately three weeks, intermittent rainfall caused interruptions in loading. The ore on the barges had to be covered over with tarpaulins and the holds on the vessel had to be closed. The crew of the vessel carried out a ‘can test’ of the ore on each barge before transfer to the vessel. If the test failed, an ‘oven drying test’ was done to determine the moisture content of the ore. If the moisture content was found to exceed the Transportable Moisture Limit (TML was 34.80%), the cargo in the barge would normally be rejected.

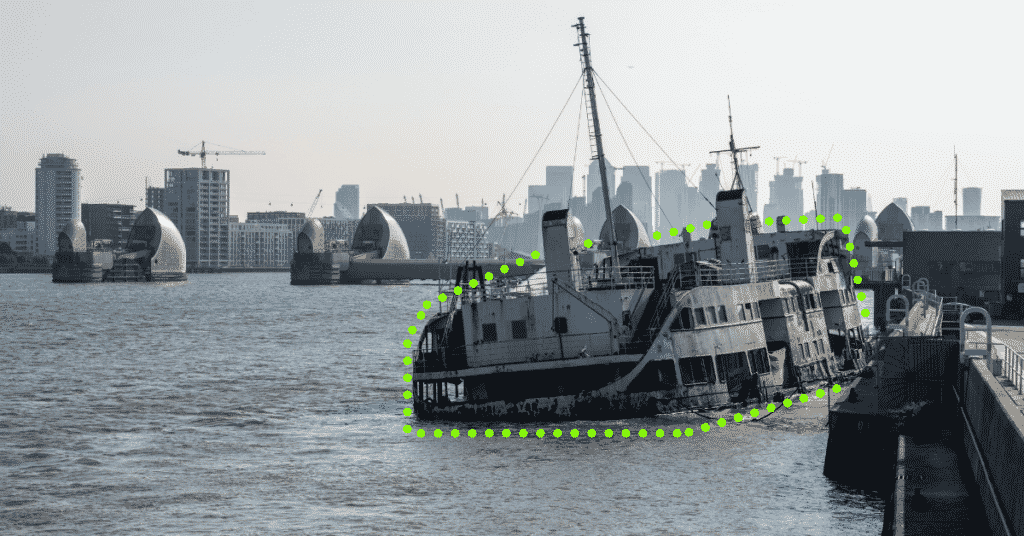

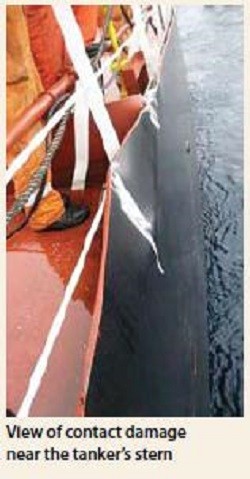

However, records indicate that on at least two occasions cargo was accepted with moisture contents of 35.54% and 37% respectively. Once the loading was completed, the holds were trimmed and pressed by means of cargo grabs; each cargo hold was about half-full. Calculations showed the vessel’s intact stability met the requirements of the International Code on Intact Stability, 2008. About a week after departure the Master had to divert due to a typhoon, eventually dropping anchor at a port of refuge that offered protection from wind and seas from the north. The vessel was yawing and rolling heavily and dredging her anchor at the anchorage due to strong winds and heavy sea, now coming from the southeast. The following day, the vessel encountered a strong wave causing her to heel to port about 20°. The vessel returned somewhat upright but was still listing about 10° to port. Within two hours the list to port increased to 45° and then 90°. Soon afterward the vessel capsized and sank.

All crew successfully abandoned the vessel before sinking and were rescued without injuries. More than 600 tonnes of oil leaked into the sea and took more than three months to clean up. The investigation into the accident revealed several contributory factors including the following:

- Nickel ore was loaded despite a moisture content that exceeded its Transportable Moisture Limit, contrary to the requirements of the International Maritime Solid Bulk Cargoes Code (IMSBC Code).

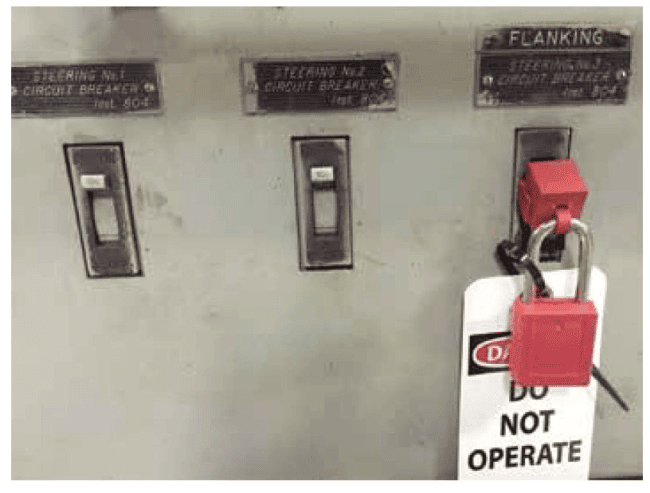

- Several of the shipboard safety procedures for loading and carriage of nickel ore were not followed.

- Due to the heavy rolling at anchorage there was liquefaction of the ore cargo.

- The Master’s selected refuge anchorage was not appropriate as the location could only shelter from northerly wind and waves. The vessel experienced strong southeasterly wind and waves when the typhoon, as predicted, passed south and southwest of the vessel’s anchorage.

The investigation also revealed the following safety issues:

- The moisture content certificate of the nickel ore was issued by the shipper instead of the local administration or independent organisation (or authorised organisation)

- The crew was not trained and therefore not competent to carry out the oven drying test to verify the moisture content of the cargo before loading.

Reference: nautinst.org

Do you have info to share with us ? Suggest a correction

- Real Life Incident: Vessel Collision in Good Visibility

- Real Life Incident: Severe Injury To Deck Crew While Leaving Berth

- Real Life Incident: Departure Damage in Very Restricted Waterway

- Real Life Incident: Low Situational Awareness Has High Impact Consequence

- Real Life Incident: Fouled Anchor in a Designated Anchorage

- Real Life Incident: Fire On Barge Carrying Scrap Metal Causes $7 Million Worth Of Damage

Latest Case studies Articles You Would Like:

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Request for ebooks, it possible

Dear sir/madam

i m a sailor and i have lots of exprience in about 13 years . Most of the cases i saw on board seniour management they are not bothered about the life. They always think that the job has to be done i any condition. They never think about the crews life even when we entered to cargo tank or hold thay does not prepared the work permit. If some one ask for the permit then they say that now time is for job priority not for the safety priority…

finally i just want to suggest you that the “””COMMANDING OFFICER OF THE VESSEL MUST LEARN HOW TO SAY NO? “”””””

Cause whenever masters gets order from charters or owner, the captain must say the true condition of the vessel.

It is suitable for loading or not or if you have any special requirements to loading or discharging then you must inform to the company or bring to the directly charter or onwer notice… but most of the master of the vessel they says “””we can do it without any problem and finally when we fucked up then we say our crew was untrained …””””

Why these incompetent crews (including captains and other officers ) are allowed to oprate these actions?

This is what I call shipping business, the crew must swallow all garbage imposed by owners, charterers, managers and operators, IMO, ISPS, SOLAS among other nonsense rules and regulations. Nickel Ore should not be carried in bulk carriers. But owners and charterers require urine tests to check if you drunk a beer or smoked a joint. We better ask owners and chaterers to carry out such tests. Sahin is right.