Dangers Of Aluminium Phosphide On Ships

A container vessel loaded some containers of Aluminium Phosphide (IMDG Class 4.3, UN No. 1397) from an Asian port. The consignment used plastic bags as inner packaging and steel drums as outer packaging. The drums were then secured on wooden pallets and these were finally stacked inside a standard marine freight container.

During the voyage, the crew heard a number of small ‘explosions’ inside one of these containers, after which some smoke escaped past the rubber seals of the door. On seeing the smoke, the crew assumed that the cargo inside was burning and sprayed water on the outside of the container exterior in order to cool it.

Although the cargo had been correctly declared at the time of shipment, the relevant Material Safety Data Sheet (MSDS) was not provided to the carrier or to the vessel. The crew was unaware of the fact that contact between water and Aluminium Phosphide produces phosphine, an extremely flammable and toxic gas. (See Editor’s note)

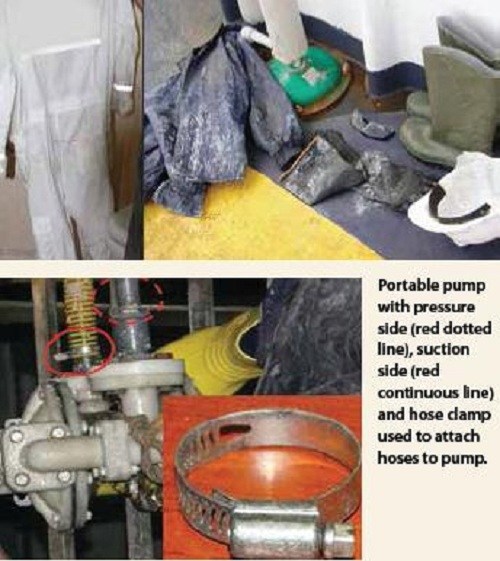

The vessel diverted to the nearest port down the coast, where the affected containers were discharged. During the discharge operation, further small explosions were heard coming from the within the other containers. The landed containers were then opened by fire-fighters and the palletised drums were removed. The ‘explosions’ were actually the sound given off by drum lids ‘popping off’ due to internal heat and gas generated by the chemical reaction.

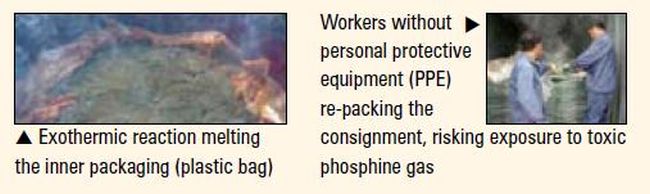

When the remaining intact drum lids were removed to access the bagged contents, there was a mild ‘pop’ and white smoke emanated from the cargo. The plastic bags were melting due to the heat generated. The attending firefighters employed dry powder extinguishers to quench the ‘fire’ in each drum.

Meanwhile, the manufacturers were contacted and they sent a team of workers to the port of refuge to repackage the cargo for onward carriage to its final destination. It was evident that these workers were unaware of the hazards of the cargo and correct handling techniques, as they casually went about their task repacking the smouldering cargo.

The manufacturers argued that the port had handled the steel drums incorrectly when they were unloaded from the containers because they allowed the contents to be exposed to the atmosphere. This allegedly caused the cargo within the drums to react with the moisture in the air, initiating a phosphine-producing reaction. Even at the port of refuge, the shippers still had not provided the vessel or the stevedores with the correct MSDS, thus exposing the ship’s crew and local workers to serious injury and health risks.

Clearly, the incident could have been very dangerous if the crew, in an attempt to extinguish the ‘fire’, had decided to pierce the containers and spray water inside, causing flammable and toxic gases to be produced in significant quantities.

It is essential that ship’s crew insist that the shipper provides them with the relevant MSDS for all potentially dangerous cargoes that are to be shipped on board, so that they can safely and properly deal with any emergency involving the cargo.

Editor’s note: Even without the correct MSDS, the ship’s crew should not have been unaware of the cargo’s properties and recommended emergency actions as it is mandatory for every dry cargo vessel to carry copies of the relevant IMO publications – the IMDG Code for packaged dangerous goods and the IMSBC Code for dry bulk cargoes. Both contain a brief description of a substance’s physical and chemical properties, general stowage recommendations and emergency action to be taken in case of spillage and fire.

Before shipping dangerous goods or bulk cargoes, such information must be understood by the ship’s command and a training session must be conducted and documented where the crew is to be properly briefed on the dangers and trained in safe handling techniques and emergency procedures. If carriage of specialised safety equipment (eg gas masks, chemical suits etc.) and instruments (eg gas and temperature measuring/monitoring devices) is recommended, it is the vessel’s responsibility to demand these and the shipper’s duty to provide them.

For UN No. 1397, the EmS (Emergency Schedule) in the IMDG Code recommends:

Wear suitable protective clothing and self-contained breathing apparatus when dealing with spillage or fire.

Avoid all sources of ignition.

Spillage:

On Deck – If dry; contain and collect spillage, where practicable, for safe disposal overboard. Avoid contact with water except to wash residues overboard with copious quantities of water. Under Deck – provide adequate ventilation. Check atmosphere before entering

space (toxicity and explosive hazards) and use selfcontained breathing apparatus. Keep dry and collect spillage, where practicable, using soft brushes and plastic trays for safe disposal overboard. If wet, use inert (non-combustible) absorbent material and dispose of overboard.

Fire: On Deck – For packages, smother with dry inert powdered material or let fire burn. Remove receptacles likely to be involved but if not practicable, cool nearby cargo with copious amounts of water. For cargo transport units if the fire is not igniting nearby cargoes, let the fire burn, otherwise cool the unit with copious quantities of water.

Under Deck – stop ventilation, batten down the hatches and use ship’s fixed fire-fighting installation (not water). Otherwise adopt action as for On Deck.

Reference: nautinst

Do you have info to share with us ? Suggest a correction

- Real Life Incident: Vessel Collision in Good Visibility

- Real Life Incident: Severe Injury To Deck Crew While Leaving Berth

- Real Life Incident: Departure Damage in Very Restricted Waterway

- Real Life Incident: Low Situational Awareness Has High Impact Consequence

- Real Life Incident: Fouled Anchor in a Designated Anchorage

- Real Life Incident: Fire On Barge Carrying Scrap Metal Causes $7 Million Worth Of Damage

Latest Case studies Articles You Would Like:

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Web Stories

What is happening in the maritime world? Handling and storage of hazardous cargos should be foremost in the minds of senior officers on board a vessels, but it is not happening. Too many take short cuts and get away with it.

My thoughts on this are companies pushing, pushing………..more speed, less haste…….time and the almighty dollar is everything. Safety takes a back seat in all too many incidents that can often result in loss of cargo, loss of a vessel and sadly the loss of lives of seafarers as well.

My dad who was ETO died onboard due to aluminum phosphide poisoning. The incident happened on Sept 2010. It was a bulk carrier loaded with wheat. He was at his cabin during during his tough time dealing with such poison. The crew on board found him missing when they made a search party they found him unconscious lying on his bed (in cabin) already dead. Ship was near Kandala, India. His body was bought to Morbi municipality hospital for autopsy. The report came after 6-8 months that the cause of death was aluminum phosphide. This was a great loss for our family. He worked with a reputed company. For complete information about the incident mail me .

I find it very disturbing that this incident didn’t even came in maritime or any local news . My father was Ex Navy Personal. He served for more than 15 years in Indian Navy before joining merchant navy.

@Dinesh: Extremely sorry for your loss and than you for sharing the information as it will help the fellow maritime professionals who are dealing dangerous cargoes onboard ship. Please email the details to anishw@marineinsight.com