Understanding Ship Stability During Dry Dock

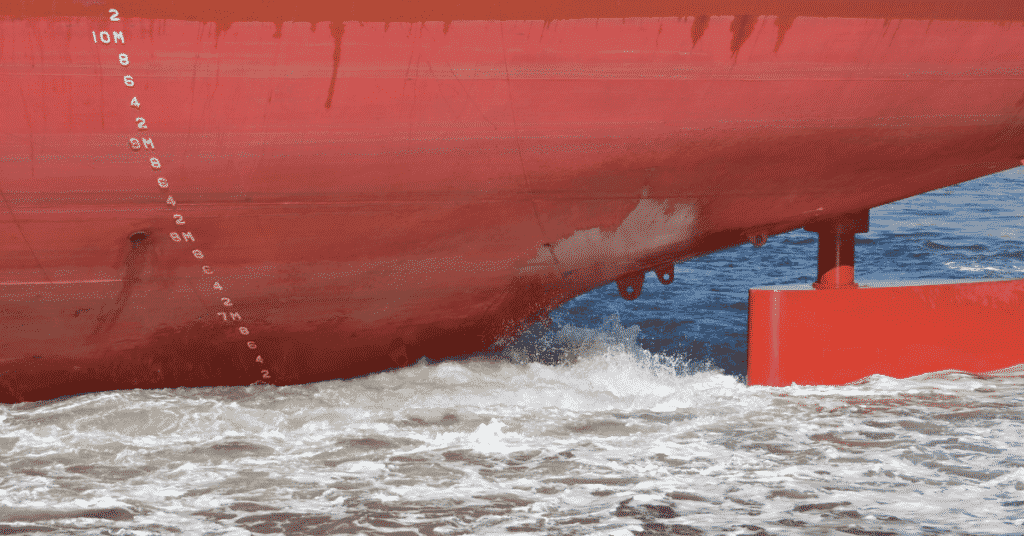

Commercial ships have to go for dry docking at regular intervals of time. During dry docking, the components of a ship exposed to the harsh environment of the seas is subjected to inspection and maintenance. This process is carried out regularly throughout the life time of a ship, depending on the construction and type of the vessel (There are special conditions for dry docking in event of inspection from classification societies, ship brought after a collision or even before a ship is sold by her owner, among others.)

The parts of the ship below the waterline are exposed to the harsh and corrosive underwater environment of the oceans. Ship’s hulls corrode, catch up bio fouling agents or can have some water tightness compromised in certain regions from a long voyage. This is why dry docking is necessary to ensure that the ship remains optimally functional throughout her life time.

Ships have deadweights running into tens of thousands of tonnes and the hydraulic lift becomes tricky to implement here, though not entirely impossible.

But why should we worry about the simple mechanical advantage offered by hydraulic lifts when a huge basin bigger than a ship can serve the purpose of lifting the vessel?

Here arises another special situation of ship stability being compromised during the process of dry docking. The ship structure may get damaged at localised locations or even on a global level if the procedure is not carried out properly.

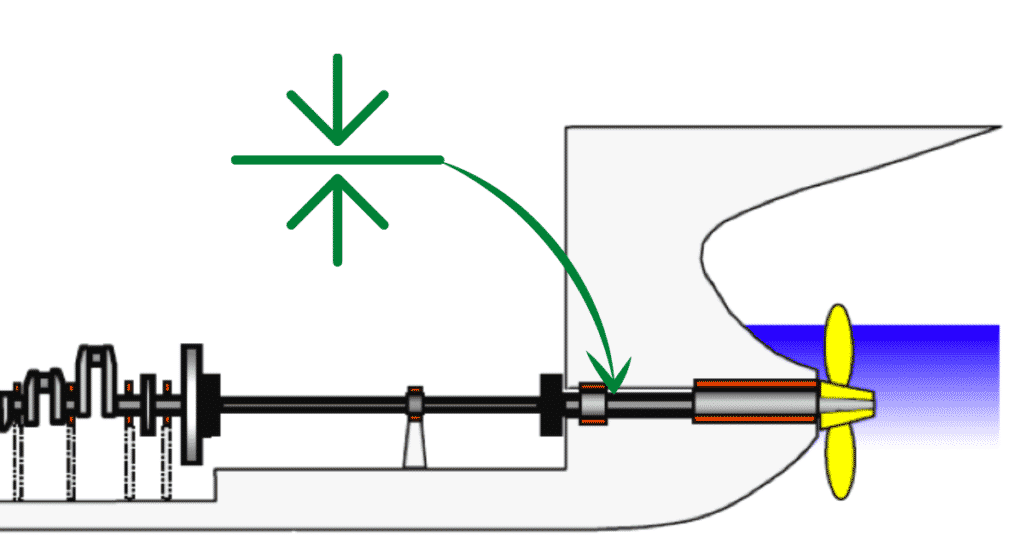

Speaking in terms of stability, what happens actually during a docking procedure is that the effective centre of buoyancy of the ship gives up the role of being the support of the vessel’s weight to the ship’s bottom reaction force. This happens gradually and this is where actual care has to be taken.

Remember the four pillars of ship stability?

The GM, BM, KB and KG vary in such situation, so that the transverse KM (KB+BM) will become zero. You know why? It is because there is no displaced volume to provide buoyant forces.

Cut to the GM, which is given by the difference between KM and KG, KG is an inherent property of the ship geometry and cannot be zero. Hence, a negative GM results in a loss of positive stability and so the ship must be supported before it topples.

Remember trim by aft being a common feature in ships when moving in water? Think about this now – when the vessel will start resting on the blocks along the entire length, it will first rest at the stern. The rest of the ship may get pivoted about this point. Now, if the vessel is able to maintain a positive GM, it won’t heel to either side, allowing a comfortable settlement.

This is rather difficult in ships with a slender form without a flat bottom. So here comes an advantage in design where it might be feasible not to design very large slender form of ships as carrying out manoeuvres would be a problem. Such ships would require side supports and the ‘bilge blocks’ in addition to the usual support.

Modern day dry docks provide side rams (operated hydraulically) as opposed to wedging with wooden shores and terraces in earlier constructions.

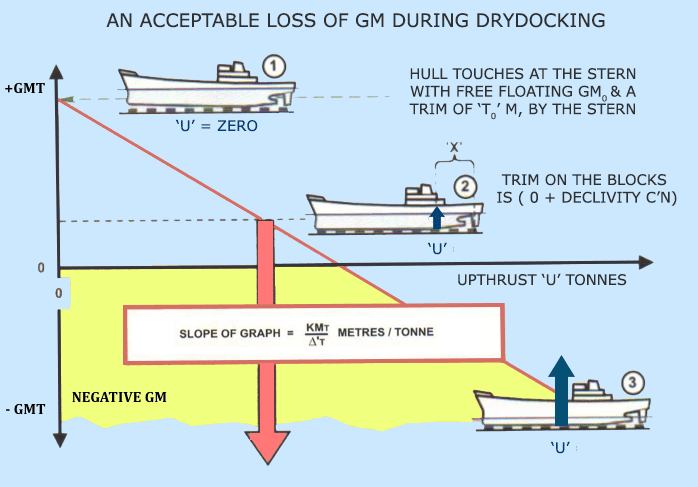

Now, you might ask, how much loss of the GM is acceptable? For this, dry docks use a graphical plot between the transverse metacentric height and the reaction provided by the blocks in supporting the vessel. What is also calculated is the docking trim (difference in forward and aft drafts) and the reaction (called the upthrust) from the blocks. The graph quite understandably has a slope KM/, which represents the loss of KM (and so the GM also) per unit tonne of upthrust equivalent added.

Another feature of a dry dock which affects your ship’s stability is what is called ‘declivity’ as mentioned in the graph above. In simple terms, this declivity is the slope expressed in terms of multiples of unit metre rise per 100 metres. It is desirable for vessels like tugs and fishing trawlers with a ‘rise of keel’ to be repaired in a dock with some declivity as they run with good propeller immersion because of the deep draft aft of these vessels.

Floating Dry docks

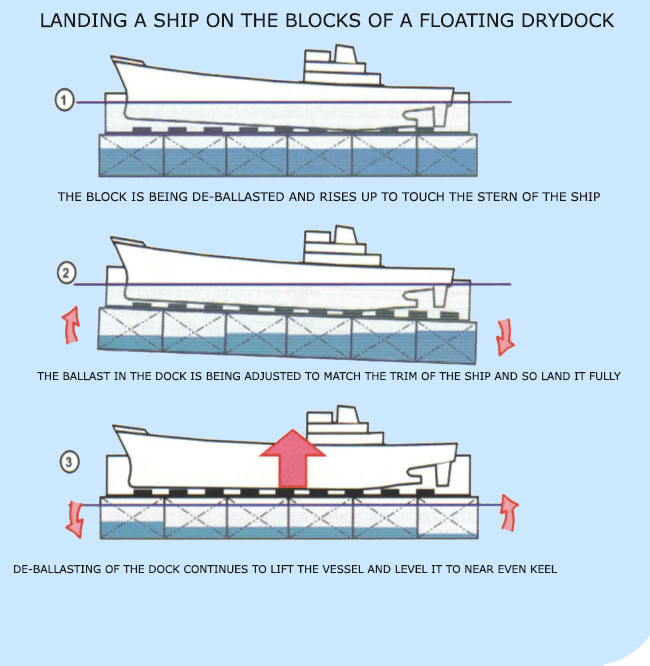

Now we come to the other type of dry docks, the ones which float. Floating dry docks have their own stability issues stemming from the fact that they have to float and bear the load of the vessel under repair at the same time. The dock has to ensure that it maintains positive stability when lifting the ship clear of water.

Here, a special manoeuvre is carried out where the dry dock matches the difference in forward and aft draft as soon as the vessel touches down at the stern, by ballasting its tanks.

So how does it maintain its own positive stability? This is where comes a restriction on the weight of the vessel that can be lifted clear of water on a floating dry dock. But, keeping that aside, we do not have the problem of a vessel heeling and loosing position on the block before the ship touches down properly on the blocks since the dry dock self-adjusts the trim like we discussed just now.

After reading this we’re sure you will have some idea about how a ship might get vulnerable and topple while being supported on a dry dock, as apparently it doesn’t seem to be such a problem at first.

Do you have info to share with us ? Suggest a correction

Latest Naval Arch Articles You Would Like:

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.