An Introduction to Tunnel Thrusters in Ships – Design and Application

Tunnel thrusters are used by ships to provide low-speed lateral manoeuvrability when docking and high thrust while at a standstill.

From design point of view, thrusters are designed as per the bollard pull condition. Traditionally, bollard pull condition refers to the amount of force a tug can apply to a bollard when secured to a pier.

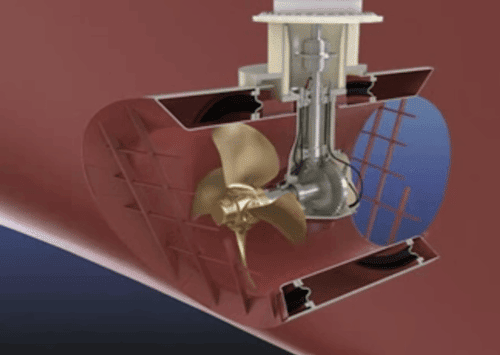

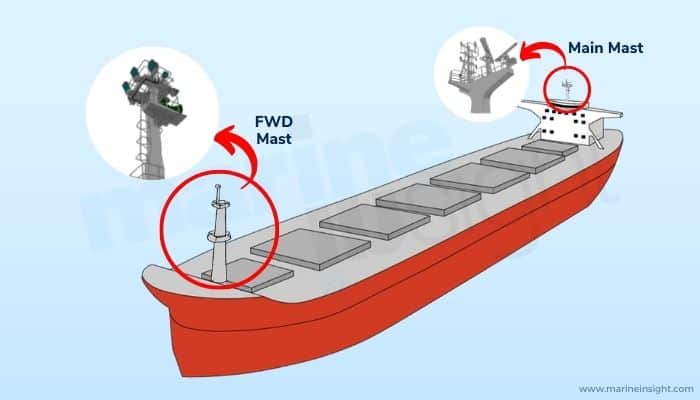

Tunnel thrusters are just like the azimuth thrusters, which are used behind a ship for propulsion, except that these thrusters are placed inside a tunnel (an opening from one side of the hull to the other) either in the forward (bow) or aft (stern) of the ship. Also, the whole setup is immovable meaning, the impeller in the tunnel can create only athwartship force.

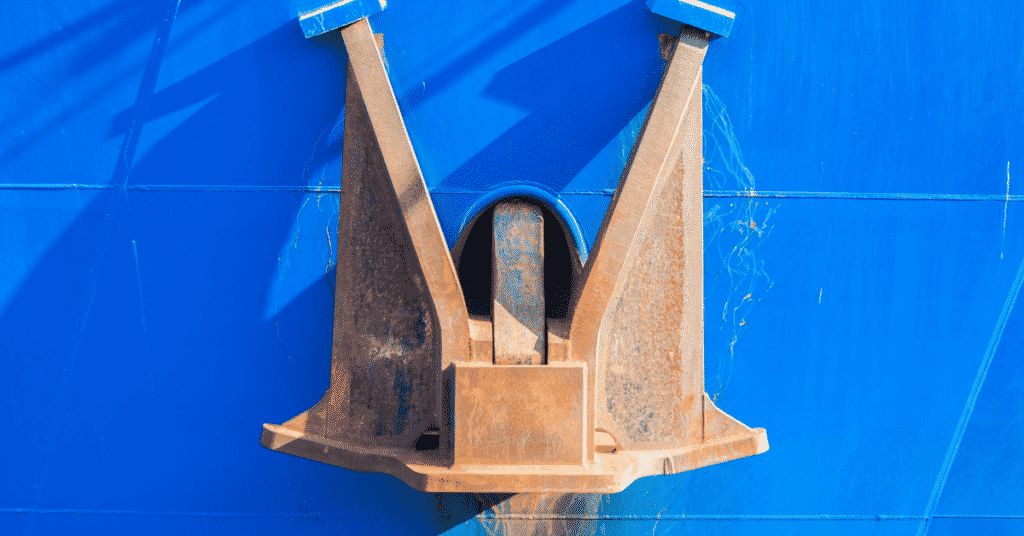

Ships equipped with tunnel thrusters can be identified by the symbol of a big cross in a red circle on both sides of the hull above the waterline over each of the thrusters. These thrusters are situated below the lowest load waterline so as to be able to always underneath the waterline.

The major purpose of tunnel thrusters usage would be during the berthing of ships, especially for very large ships such as VLCC, Aframax, Panamax, Passenger vessels (Ocean liners & Cruise ships), in heavy wind and tide conditions.

They are also used by research vessels during collecting samples or launching AUV’s or ROV’s which require the ship to remain still. They shorten the time of manoeuvring and reduce the cost of towage. Also, since inception of tunnel thrusters manoeuvrability specifically in ports has become a lot easier. They can either be operated manually or with the help of DP systems (Dynamic Positioning) which makes it even more efficient as the later can operate on their own by just setting the position through the feedback mechanism.

Tunnel thrusters found on ships as –

1. Bow Thrusters (Water-jet Bow Thrusters, conventional bow thruster & Hydraulic tunnel thrusters)

2. Stern Thrusters

Water-jet bow thrusters is a special type of thruster that utilises a pumping device instead of a conventional propeller. The water is discharged through nozzles with high velocity. They have a greater advantage of smaller hull penetrations for an equivalent size thrusters.

Stern thrusters are just like the conventional propeller tunnel thrusters. They are used for increased stability and better turning ability (about its midship).

Pros and Cons

Having a tunnel thruster installed is definitely advantageous, but as we all know there are two sides of ever coin. Therefore tunnel thrusters have got their own disadvantages as well.

- They can sometimes affect the efficiency by increasing the resistance to forward motion through the water. However, this is mitigated by proper fairing of the aft of tunnel aperture.

- Ship operators should take care of the impellers and the tunnel, either through the use of protective grate or cleaning, to prevent fouling.

- They consume a lot of power and require a separate DG set to power the impellers, thereby, increasing the fuel consumption.

- Installation, repair and maintenance cost can sometimes be a problem as they are quite expensive and complex systems to handle with.

However, looking through the brighter side of it –

- Installation cost compensates the working efficiency.

- They may seem to consume a lot of power (hence, fuel), but at the same time they also save a lot (fuel) by avoiding unnecessary manoeuvring, which is quite unavoidable without tunnel thrusters.

Design

Based on design, the family of thrusters can be divide into CPT (Controlled Pitch Thruster) and FPT (Fixed Pitch Thruster). They are designed to achieve maximum thrust for a specific propeller diameter and guaranteed maximum efficiency.

Tunnel thrusters of type CPT are equipped with Controllable Pitch Propellers. The torque developed due to the propulsion motor is transmitted by elastic coupling and bevel-gear to the shaft on which the hub of the propeller is mounted. The direction of thrust is controlled by means of a change of the pitch propeller. The change of pitch is controlled by a hydraulic method.

Tunnel thrusters of type FPT are equipped with Fixed Pitch Propellers. The direction of the thrust is obtained by means of a change of rotation direction in the propulsion motor. The thrust is controlled by a change in the number of motor revolution.

During vessel design, it is important to determine whether tunnel emergence above the water surface is commonplace in heavy seas. Tunnel emergence hurts thruster performance, and may damage the thruster and the hull around it.

Following are some design parameters which increase technical benefits –

- The tunnel diameter should be as small as possible so as to minimise the mounting space and increase hull efficiency.

- Tunnel thruster should be designed for maximum thrust.

- High efficiency should be obtained by adapting the propeller design to the tunnel diameter, and to optimise the flow towards the propeller.

- Standard blades of backward skewed design with rounded tips should be designed. This results in optimum thrust efficiency while obtaining a more gradual change in the cavitation volume.

- The propeller should have a large blade area so as to keep cavitation volume as low as possible. This results in maximum thrust output at minimum noise and vibration levels, giving optimum comfort in the accommodation.

Following points are to be considered if you are ordering a tunnel thruster –

- The components of the tunnel thrusters have to be reliable and durable.

- Bearings and the gears should have a long lifetime.

- The thruster should offer high efficiency.

- The thruster should be design in such a way that the components a maintenance friendly.

Over to you..

Do you know any other important information on tunnel thrusters that can be included to this article?

Let’s know in the comments below.

Do you have info to share with us ? Suggest a correction

Latest Naval Arch Articles You Would Like:

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

I want to thank you for the informative article on the subject of stern and bow thrusters. I am looking at having two different vessels retro-fitted with thrusters and enjoyed the information that you supplied in this article. I would greatly appreciate any information about water type thrusters vs propeller type thrusters with regard to cost of installation and on-going maintenance issues. Thank-you, D. Leo Lund.

The RIM drive thusters are the highest standard for bow- and sternthusters. High efficiency, extremly silent and very compact.