How to Identify Metals in Engine Room? – Observation and Spark Test

Engine room is full of machinery and pipelines that are made of different metals and alloys. Before repair and fabrication is done, it is imperative that the metal be identified so that successful repair is possible.

The first rule when selecting welding electrodes is that it must be equal or superior to the parent metal. (Read the Guide to Welding Electrodes on ships) Some metal are easily identifiable by color and weight, but some like ferrous alloys are very difficult to differentiate from each other. A marine engineer must be conversant about the identification of metals on ships.

The metals can be identified by various tests such as spark test, flame test, chip test, fracture test, file test, hammer test and plain observation. We shall discuss all the methods one by one.

It is very easy to distinguish aluminum from stainless steel and copper from brass and metal like lead from other metals. However trying to differentiate one group of ferrous metals from the other is difficult. A basic classification may help in determining if welding is indeed possible and if so what type of electrode must be used.

Observation and Surface Examination

You can know very certainly whether it is a casting or a forging. Similarly you can know whether it is ferrous or non ferrous metal. Also, special fabrication methods like sintering can be known. Given below are some points and tips in identification of metal by observation:

- Cast iron and Cast steel can be identified by casting marks of sand mould and where risers and feeders have been cut off.

- Low carbon steel sometimes may have forging marks.

- High carbon steel may have rolling marks.

- Lead is smooth and has a velvet type of feel.

- Aluminum and its alloys can be identified by the lightness.

- Grey cast iron has a dull grey appearance roughened by sand mould. Machined surfaces may be smooth but brighter areas.

- Malleable cast iron is lighter and smoother than grey cast iron.

- Low carbon steel appearance depends on the method of its preparation. Cast steel has a rough dark surface except where it has been machined. Rolled steel has fine lines all running in one direction. Forged steel is identifiable by the forging marks and hammer marks.

- Cast steel is brighter than cast iron and has small bubble like depressions.

- Brass and bronze have color from red to yellow and on oxidation they have colors like green, brown and yellow depending on composition.

- Copper is reddish in color and oxidizes to green in color.

- Lead is dull grey in color and very heavy. A freshly cut piece is white in color.

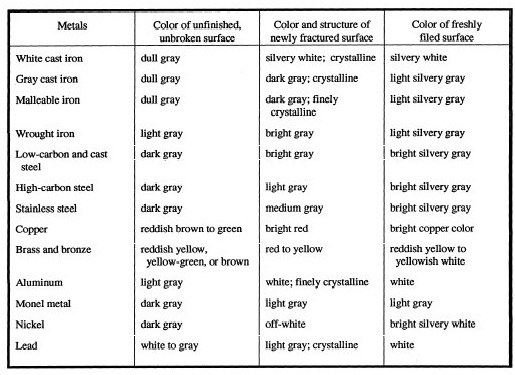

The table below gives identification of various metals and alloys based on look of whole piece, fractured piece and filed piece.

Spark Test

The spark test is one of the simplest test methods of identification of the metal and is reasonably accurate. However for this test there is a need of good power of observation and a dark or diffused background. The only restricting point about this test method is that it slightly damages the sample.

A spark test is done by holding the test piece against a grinding wheel. When a piece or iron or steel is held against the rough surface of the grinding wheel the metal particles are removed and due to friction they become hot and glow. These removed metal particles which glow while leaving the parent metal are called sparks.

These sparks are different depending on the composition of the metal or alloy. Studying these spark patterns can help in identifying the metal fairly closely. The sparks given, their length, color and formation can identify the metal. This test is applicable for ferrous based metals.

If carbon is present in the metal its burns brightly when oxidized. Thus a variation in the percentage of carbon in the metal will result in sparks of various lengths, color and shape.

The procedure for carrying out a spark test is as follows:

- A bench grinder or a portable grinder must be used. The peripheral speed of the grinder should be higher than 4000 to 4500 feet per minute.

- The grinding wheel must be coarse and kept clean to produce a true spark for identification.

- Hold the metal piece in such a way that sparks streak across your line of vision. Adjust the pressure accordingly to produce sufficient length of sparks.

- Pressure must be correct otherwise excess pressure will make the sparks glow brighter and will give a wrong impression that the carbon content of the metal is higher.

- Mentally divide the spark stream into three parts and observe the last part from the end for identification.

- Do not move your head trying to catch the sparks but only observe those sparks that cross your line of vision.

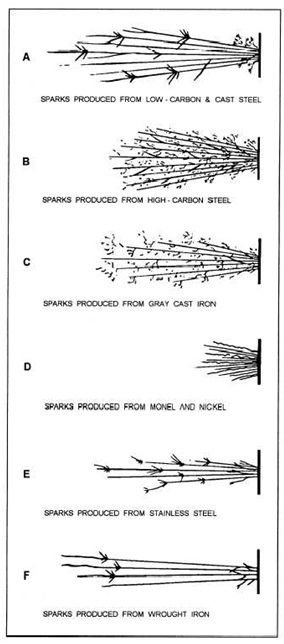

The figures below give the spark patterns of different metals and alloys.

References

Esabna , sweethaven , tpub

METAL, PROPERTIES, CHARACTERISTICS, USES AND CODES: AIPD US ARMY

Image credits

seattle

Do you have info to share with us ? Suggest a correction

Latest Shipboard Guidelines Articles You Would Like:

About Author

Chief Engineer Mohit Sanguri is a Marine Chief Engineer (Class I Unlimited Power). He has 12+ years of experience as a Marine Engineer.

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.