Permanent Magnet Moving Coil Instrument (PMMC) – Working and Application

Several electrical machines and panels are fitted onboard ships to sail from one port to another safely and efficiently.

The electrical machinery and system require scheduled maintenance and checks to avoid any breakdown during sailing.

Different instruments are used onboard for measuring several electrical parameters to analyze and keep these machines in proper running condition.

A permanent magnet moving coil (PMMC) is one such instrument that is popularly used onboard and has several applications. The other popular nomenclature of this instrument is D’alvanometer and galvanometer.

Permanent Magnet Moving Coil: Principle of Working

When a current-carrying conductor is placed in a magnetic field, it experiences a force and tends to move in the direction as per Fleming’s left-hand rule.

Fleming left-hand rule:

If the first and the second finger and the thumb of the left hand are held so that they are at a right angle to each other, then the thumb shows the direction of the force on the conductor, the first finger points towards the direction of the magnetic field and the second finger show the direction of the current in the wire.

Equation involved

The interaction between the induced field and the field produced by the permanent magnet causes a deflecting torque, which results in rotation.

The three important torque involved in this instrument are:

Deflecting torque:

The force F, which will be perpendicular to both the direction of the current flow and the direction of the magnetic field as per Fleming’s left-hand rule, can be written as

F = NBIL

where N: turns of wire on the coil

B: flux density in the air gap

I: current in the movable coil

L: vertical length of the coil

Theoretically, the torque (here electro-magnetical torque) is equal to the multiplication of force with distance to the suspension point.

Hence Torque on the left side of the cylinder TL = NBIL x W/2 and torque on the right side of the cylinder TR = NBIL x W/2

Therefore the total torque will be = TL + TR

T = NBILW or NBIA where A is an effective area (A= LxW)

Download Practical Maritime eBooks With Amazing Bonuses:

Here are a few fantastic ebooks to get important maritime information in the next couple of minutes!

Controlling Torque

This torque is produced by the spring action and opposes the deflection torque so as the pointer can come to rest at the point where these two torques are equal (Electromagnetic torque = control spring torque). The value of control torque depends on the mechanical design of spiral springs and strip suspensions.

The controlling torque is directly proportional to the angle of deflection of the coil.

Control torque Ct =Cθ where, θ = deflection angle in radians and C = spring constant Nm /rad .

Damping torque

This torque ensures the pointer reaches an equilibrium position, i.e. at rest in the scale, without oscillating to give an accurate reading. In PMMC, as the coil moves in the magnetic field, eddy current sets up in a metal former or core on which the coil is wound or in the circuit of the coil itself, which opposes the motion of the coil, resulting in the slow swing of a pointer and then come to rest quickly with very little oscillation.

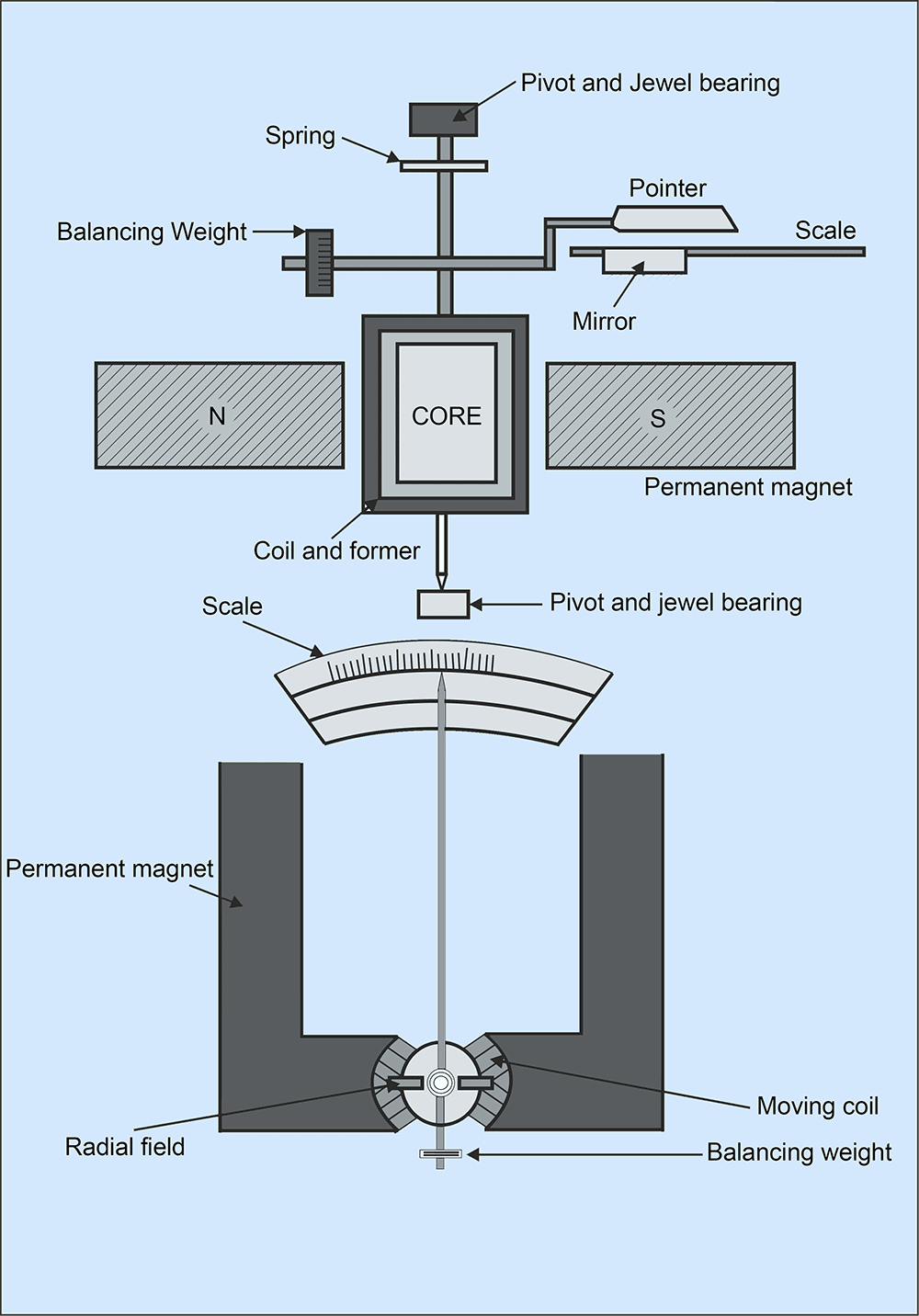

Construction of PMMC

A coil of thin wire is mounted on an aluminium frame (spindle) positioned between the poles of a U shaped permanent magnet, made up of magnetic alloys like alnico.

The coil is pivoted on the jewelled bearing, and thus the coil is free to rotate. The current is fed to the coil through spiral springs, which are two in numbers. The coil which carries a current, which is to be measured, moves in a strong magnetic field produced by a permanent magnet and a pointer is attached to the spindle, which shows the measured value.

Working of PMMC

When a current flows through the coil, it generates a magnetic field proportional to the current in an ammeter. The deflecting torque is produced by the electromagnetic action of the current in the coil and the magnetic field.

When the torques are balanced, the moving coil will stop, and its angular deflection represents the amount of electrical current to be measured against a fixed reference, called a scale. If the permanent magnet field is uniform and the spring linear, the pointer deflection is also linear.

The controlling torque is provided by two phosphorous bronze flat-coiled helical springs. These springs serve as a flexible connection to the coil conductors.

Damping is caused by the eddy current set up in the aluminium coil, which prevents the oscillation of the coil.

Applications

The PMMC has a variety of uses onboard ships. For example, it can be used as:

1) Ammeter:

When PMMC is used as an ammeter, except for a minimum current range, the moving coil is connected across a suitable low-resistance shunt so that only a small part of the main current flows through the coil.

The shunt consists of several thin plates of alloy metal, which is usually magnetic and has a low-temperature coefficient of resistance, fixed between two massive blocks of copper. A resistor of the same alloy is also placed in series with the coil to reduce errors due to temperature variation.

2) Voltmeter:

When PMMC is used as a voltmeter, the coil is connected in series with high resistance. The rest of the function is the same as above. The same moving coil can be used as an ammeter or voltmeter to interchange the above arrangement.

3) Galvanometer:

The galvanometer is used to measure a small value of current along with its direction and strength. It is mainly used on board to detect and compare different circuits in a system.

5) Ohm Meter:

The ohmmeter is used to measure the resistance of the electric circuit by applying a voltage to resistance with the help of a battery. A galvanometer is used to determine the flow of current through the resistance. The galvanometer scale is marked in ohms, and as the resistance varies since the voltage is fixed, the current through the meter will also vary.

Advantages of PMMC

- The PMMC consumes less power and has great accuracy.

- It has a uniformly divided scale and can cover an arc of 270 degrees.

- The PMMC has a high torque to weight ratio.

- It can be modified as an ammeter or voltmeter with suitable resistance.

- It has efficient damping characteristics and is not affected by a stray magnetic field.

- It produces no losses due to hysteresis.

Disadvantage of PMMC

- The moving coil instrument can only be used on D.C supply as the current reversal produces a torque on the coil.

- It’s very delicate and sometimes uses an AC circuit with a rectifier.

- It’s costly as compared to moving coil iron instruments.

- It may show an error due to the loss of magnetism of the permanent magnet.

What are the different reasons that cause an error in PMMC?

- Temperature effect: Error in the reading of the PMMC may cause a change in the temperature, which will affect the resistance of the moving coil. The temperature coefficients of the value of the coefficient of copper wire in the moving coil are 0.04 per degree Celsius rise in temperature. Since the coil has a lower temperature coefficient, it will have a faster rate of temperature rises, resulting in an increase in the resistance, causing an error.

- Spring material and age: The other factor which may lead to error in the PMMC reading is the quality and contortion of the spring. Old ageing spring will not allow the pointer to show the correct reading making an error.

- Ageing of Magnet: Along with age, the effect of heat and vibration will reduce the magnetic effect of the permanent magnet, which will produce an error in the reading.

Can PMMC be used to measure AC?

If the frequency is low enough, the PMMC with a rectifier can measure AC, which converts the measured quantity into a DC typically less than 1mA. Add an appropriate scale, and you have a meter.

What will happen if I use it with high-frequency AC?

If the frequency of AC is high, the meter vibrates in and around the zero value (preferable to verify with a centre zero meter) and finally stops responding to the AC.

What are permanent magnets made of?

Permanent magnets are made of special alloys such as :

- Aluminum-Nickel-Cobalt (Alnicos)

- Strontium-Iron

- Neodymium-Iron-Boron

- Samarium-Cobalt.

You might also like to read:

- 10 Ways to Achieve Energy Efficiency in Ship’s Electrical System

- Importance of Insulation Resistance in Marine Electrical Systems

- Maintenance of Electrical Relay on Ships Electrical Circuit

- 10 Electrical Jobs Marine Engineers Must Know On Board Ships

- Single Phasing in Electrical Motors: Causes, Effects, and Protection Methods

Disclaimer: The authors’ views expressed in this article do not necessarily reflect the views of Marine Insight. Data and charts, if used, in the article have been sourced from available information and have not been authenticated by any statutory authority. The author and Marine Insight do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendation on any course of action to be followed by the reader.

The article or images cannot be reproduced, copied, shared or used in any form without the permission of the author and Marine Insight.

About Author

Raunek Kantharia is a marine engineer turned maritime writer and entrepreneur. After a brief stint at the sea, he founded Marine Insight in 2010. Apart from managing Marine Insight, he also writes for a number of maritime magazines and websites.

Do you have info to share with us ? Suggest a correction

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Web Stories

gud one.

Helpful 🙂

vry nice i got some importent information

It make so easy.thank’s.

an equation for moving coil instrument

good…..

Information provides which is very good

construction of Fm radio transmiter

shrot nd effective

need an another diagram for pmmc

sir, you are best

very very good…………..

construction of pmmc is not clearnplz help me my frnd…..

Nice…..

It is wonderful.

Sir! Plz give the equastions…

sir,u r the best…

Information provides

which is very good

we should learn this . it will be helpful in chapter magnetic effect of electric current.

Wot happend if d polarity is been interchange ….pls urgent answer. Thanks

Is the permanent magnet moving coil have no controlling torque?

@ Shafy:

Check this paragraph in the above article- “The controlling torque is provided by two phosphorous bronze flat coiled helical springs. These springs serve as a flexible connection to the coil conductors.”

The measurement of current ,resistance and voltage ans. is very simple to understand but i have also needed the connection diagram of all…

plz add good image of pmmc

Pls are need u 2 help me out 4 a projet in my school, the type of projet that I will construt, and also the materias too, am studind mechanical engineering, 200 level am from Nigeria.

Why pmmc galvanmtr can not use for AC measurements. .?

its satisfactory, but plse give equations

good

pmmc matter is very nice and simple to understanding. sir plz give equations

Satisfied

Superb….

hmmm aik question nikal gaya 🙂

PMMC Explanation is very short but athuntic

thank you very much it is very helpfull for me

it is too good to understand

it is the very very important for human life….thank’s

it is the very very important for human life….thank’s

Excellent to understand

Very helfull

Very easy language

very simple language is used and easy to understand the concept. i like ut very much.

sir it is best this good for human life and for student

The explanation of PMMC is quiet clear buh you do not mention of FLUX and ORIFICE,, please i wish you can throw more light on the aboved mention

very simple language is used and easy to understand the concept I Like it very much

very clear and full information

Thanks,I’ve learnt alot….

Simple and clear

thnx

Gud one…easy to understand..

explain what happens when the leads of a megger are short circuited

The pointer rests at zero because the current in coil a is relatively large.

Sir good effort for other student i like it sir thank u

Understandable…

Why can always dc votage in PMMC

Hi,

I was researching about your company and got to know you’re participating in HFMA Annual Conference 2018.

Would you be interested in acquiring database of * Healthcare Financial Management Industry Emails List * with top level decision makers emails and phone numbers across USA? This list can be customized as per your requirements and can be used effectively for rolling out email marketing campaign, direct mailing and tele calling purposes.

Our Services: Email Lists, Email Appending, Email Campaign, Lead Generation, etc.

Get thoroughly verified data for best in class accuracy and relevancy from the leading B2B and B2C data supplier.

Let me know your specific Target Criteria (Any Industry Type / Geography) you wish to reach, I can get back to you with more relevant information, counts and pricing.

Regards,

Mariawilson

Business development executive

Note: To unsubscribe, please mention the same in subject.

Dear Sir,

I have been manufacturing PMMC meters for nearly 50 years.

In the end you have listed types of permanent magnets. But you have not given the details of which type is useful In professionally made PMMC meters. Mostly only Alnico magnets are used. Very coarse instrument such as battery charging / discharging indicators may use Strontium Iron ( Ferrite Magnets ). The main problem with ferrites is low magnetic flux density and much higher temp co-efficient. So 10 deg change in ambient temp. can degrade accuracy by 2 %. Neodymium-Iron-Boron magnets are very strong and very good mechanically, but temperature co-efficient is again a discouraging factor. Samarium Cobalt is a very good candidate w.r.t. temperature co-efficient, but since it is hard and brittle, the chances of magnet getting destroyed accidentally are high and no manufacturer can take responsibility for a fragile product. Hope this information will be useful to the readers of your post. Cost is a minor factor except in the case of ferrites which are very cheap. The Neodymium-Iron-Boron and Samarium Cobalt are expensive, but size can be reduced since they are capable of much higher magnetic flux densities compared to Alnico Magnets. The other limitations of both types are as given above.