Variable Injection Timing (VIT): What Marine Engineers Must Know?

The Variable Injection Timing (VIT) function of a marine diesel engine comes into play during load dependent adjustment of the combustion pressure. Variable Injection Timing (VIT) allows to achieve maximum combustion pressure during part load operation which helps in decreasing the fuel consumption and also achieve efficient combustion in the engine.

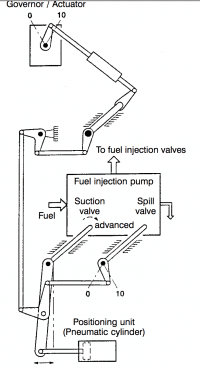

By controlling the injection timing of the fuel in the fuel delivery pump and advancing the fuel pump injection timing, VIT increases the maximum pressure in the engine.

When working with a ship’s Main Engine, which is equipped with Variable Injection Timing (VIT) device, a marine engineer must know the following points for smooth engine operation:

1. Freeness of Mechanical Parts: The actuator of Variable Injection Timing (VIT) operates on the movement of eccentric shaft of suction and spill control valves. Marine engineers must ensure that these valves are free from any obstruction or excessive play. The eccentric shaft spring should also be regularly checked for proper operation in order to avoid any kind of breakdown.

2. Checking Load Indicator Values: The regulating fuel linkage transmits the movement of the governor output lever and determines the fuel feed to the cylinder accordingly. Ship’s engineer’s must check the correspondence between the load indicator position in the setting plate provided in the linkage, and the load indicator value at the local manoeuvring stand and at the remote control position when the VIT is set to “0”. If there is deviation in any of the three values, it has to be corrected before commencing any action on the fuel pump timing.

3. VIT Actuator Setting: Check the actuator stroke when VIT is “0” by inserting the distance sleeve between the suction valve regulating lever and the blocking unit. Move the VIT to its maximum advance and minimum retard position respectively and note down the values in the load indicator in the setting plate. Also check the stroke of the actuator at the remote control system. Lastly, note and compare any deviation prescribed in the manufacturer manual.

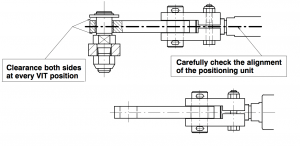

4. VIT Clearance: When fitting the VIT after maintenance, the clearance and alignment between the stop plate and the linkage must be checked with cylinder in fully retracted position. If there is no clearance, the stop plate must be ground until the clearance is achieved.

5. Electrical Connection: For electronically operated Variable Injection Timing (VIT), all the cable connections between the connecting box and VIT terminal must be checked regularly.

6. Pneumatic Cylinder: The Pneumatic cylinder which acts as the positioning unit of the VIT linkage is sometimes provided with a mechanical stoppage which should be checked for jamming. This will be useful to move the cylinder manually in the event of failure of automatic positioning system.

7. Running in Period: When the marine diesel engine is under breaking in/ running in period due to rent overhauling of the engine components, VIT should be disconnected or turned off for the complete time period until the running in is completed.

8. Engine running with Unit Cut Off: If the main engine is running with one unit cut-off due to major problem in the parts of that unit, the VIT to be set at zero or switched off as there will be uneven load distribution within the engine.

9. VIT Failure: When the failure of VIT occurs, the combustion peak pressure is no more controlled by the pneumatic actuator. During such situation, the distance sleeve must be installed to fix the neutral position of the VIT.

This is not an exhaustive list but comprises of all the important points that must be considered while working on an engine with VIT.

VIT is used to reduce the overall fuel consumption and to achieve maximum pressure even at low load but poor maintenance and operation of VIT can reverse the result and even lead to major damage of main engine parts.

Do you know any other important point that should be added to the list? Let’s know in the comments below.

Do you have info to share with us ? Suggest a correction

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Web Stories

About Author

An ardent sailor and a techie, Anish Wankhede has voyaged on a number of ships as a marine engineer officer. He loves multitasking, networking, and troubleshooting. He is the one behind the unique creativity and aesthetics at Marine Insight.

it is very use full thing for marine engineers. i give thanks for all who participate this program

I am marine engineer and interested to know like this critical information

Thanking you.

it is very easily to understand. thankyou all faculties

What will happen if vit cease in different positions and its affect on indicator ,draw diagram ?

After major overhaul of Mitsubishi UE fuel pumps it is critical to ensure that the dots on the rack and pinion (as viewed from the bottom of the pump looking inside) are correctly aligned.

The external index indications on the pump rack and VIT indicator in the case in point were all the same throughout the engine, but due to incorrect assembly of the pump VIT rack for fuel pump barrel positioning, the cylinder in question was consistently showing an 8 bar low peak pressure.

A difficult problem to analyse and particularly when the pumps had all been overhauled.

@John: Thank you for sharing this. It surely will be helpful for people working in Mitsubishi engine.

Dear Anish

First, I would like to congratulate you about your articles as they have been a helpful tool against various troubleshooting problems.

Having this in mind I would like to ask for your opinion about the analyses of a diagnoses report where VIT index has a range between 0 and 10 but all values (each cylinder) were above 30.

What should be my interpretation from this? That Pmax is achieved very early in cycle, and by doing so it fuel consumption increases?

Any comments from your side will be well received.

Thank you in advance

Why there is no VIT on 4 stroke engines?

Why is it during 30% load of main engine the pressure for VIT actuator becomes zero then the VIT rack position is negative.

Nice post keep it up, I must say that I learnt something in this post. Please I would like to ask for your help or advice on how I could reach a company that I can do my sea time training with as engineering cadet as it is very important for me to be competent.