Real Life Accident: Ship’s Fourth Engineer Dies From Observation Glass Explosion

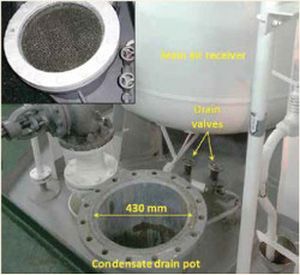

The fourth engineer started his engine room checks, which included draining accumulated water (condensate) from the main and auxiliary air receivers. He opened each of the two inline drain valves of the forward main air receiver about one turn and stood by, watching the flow of condensate through the observation glass of the drainage pot. Shortly afterwards, and without warning, the observation glass exploded.

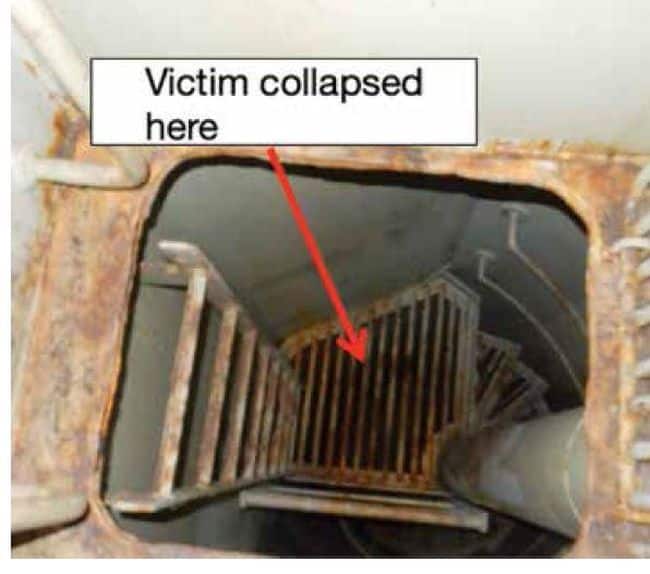

The fourth engineer was found seriously injured, breathing but unconscious. After shutting the two air receiver drain valves to stop the flow of escaping air, first aid was administered to the victim. About 30 minutes later the victim stopped breathing. Cardio-pulmonary resuscitation was immediately performed by crew members. Shortly thereafter paramedics arrived by helicopter and assessed the situation, but it was too late; the victim was confirmed dead.

An analysis of the accident showed it was likely that condensate had accumulated in the air receiver overnight. When the drain valves from the main air receiver were opened, the condensate flowed into the drainage pot in sufficient quantity to cover the bottom of the pot and the discharge hole. This flow of liquid was probably followed by a marked increase in pressure due to the inrush of pressurised air (about 30 bar) from the receiver. The pressure increase in the drainage pot was sufficient to fracture the observation glass, leading to its catastrophic failure. The positioning of the drain valves behind the observation pot meant that the fourth engineer’s upper body was positioned directly over the observation glass and therefore in the path of the explosive force and debris from the pot.

|

|

|

The condensate drain pots fitted on the vessel were not of a design normally fitted by the builder, or commonly encountered on board ships. They were a modification that was implemented at the request of the shipowner’s representative to eliminate splashing of condensate. He had provided notes outlining the fitting of glass observation windows. Although the design of the drainage pots suggests that some consideration was given to the likelihood of pressure accumulation, no quantitative engineering analysis of the design was undertaken. When considering the working conditions and component deterioration over time, failure of the observation glass at some time in the future was almost inevitable. Importantly, any failure would probably occur while the operator was positioned over the observation glass to operate the valves or to look into the pot, as in this case.

Compressed air systems are a vital service on board a ship and as such are subjected to class scrutiny. However, the drainage systems and their components, particularly open ended piping, are not regarded as being under pressure and are not normally considered to be classed items. The information and drawings available on board the vessel at the time included the final (approved) drawing for the compressed air system but did not mention the modified drainage pots or the closed drain system. The modified drainage pots and the enclosed drain system should have been brought to the attention of class by the shipyard and subject to design scrutiny prior to being installed and used, as this was both a modification and exposure to pressures in excess of 7 bar.

Official report findings

- The drainage pot observation glass failed catastrophically when the pot was subjected to significant air pressure from the pressurised air receiver. Pressure accumulated in the drainage pot when liquid condensate from the air receiver restricted the flow of air and liquid out of the pot into the drain piping and to the bilge.

- The shipyard did not follow its own procedure for fitting a modification required by the ship owner’s representative. Consequently, the shipyard did not conduct appropriate engineering analysis or testing of the condensate drain system prior to fitting it. They were, therefore, unable to establish the extent or impact of pressure accumulation and operating conditions on the system.

- Both the shipyard and the owner’s representative considered the drain system to be open and therefore not prone to pressure accumulation. They did not appropriately consider the significance of any possible pressure build-up in the drainage pot.

- The condensate drainage pots fitted to vessel’s main air receivers were not fit for purpose as they were not capable of withstanding the internal pressures that were likely to accumulate in service.

Editor’s note: When in doubt,or for any ad hoc modifications to vital machinery, consult class.

Do you have info to share with us ? Suggest a correction

- Real Life Incident: Vessel Collision in Good Visibility

- Real Life Incident: Severe Injury To Deck Crew While Leaving Berth

- Real Life Incident: Departure Damage in Very Restricted Waterway

- Real Life Incident: Low Situational Awareness Has High Impact Consequence

- Real Life Incident: Fouled Anchor in a Designated Anchorage

- Real Life Incident: Fire On Barge Carrying Scrap Metal Causes $7 Million Worth Of Damage

Latest Case studies Articles You Would Like:

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Yes a refitting done without thinking the result of such action.Pressure accumulation and the glass observation integrity.Safe working practice or rather malpractice.