Accidents at Sea: Steam Leak Causes Death

Burns and injury caused by steam are known to be more severe than those caused by hot water. Accidents on ships because of steam leakage are very common. However, when such incidents lead to death, it’s a matter of great concern.

In this article, we have described a real life accident wherein one seafarer lost his life because of steam leakage and other was severely hurt.

Incident

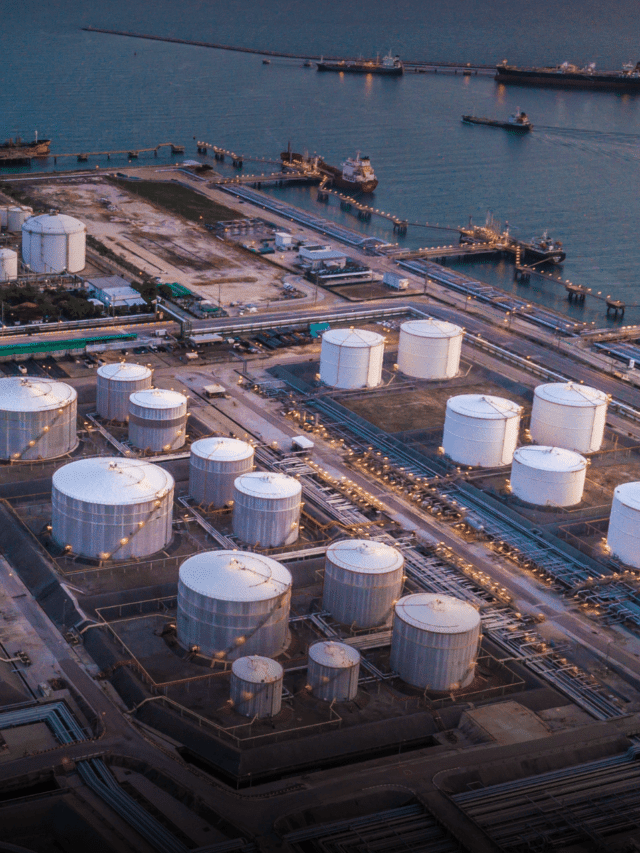

The incident took place on a cargo ship where economizer and auxiliary boiler were two separate units. One of the flanges in the line from boiler to economizer was leaking because of a broken gasket. This was noticed just before the ship’s arrival at the port.

When the ship was berthed, the boiler was stopped and job of changing the leaky gasket was assigned to ship’s 3rd engineer and fitter.

The leaky flange was at a higher level and thus a platform was rigged to reach the flange and carry out the necessary work. In the meantime, the circulating valve on the boiler for the economizer was found leaking which lead the boiler pressure drop to 0.5 bars.

The fitter wore a helmet, safety shoes, and a safety belt. The belt’s safety line was tied to a nearby bracket. Both 3rd engineer and fitter were on the platform to change the defective flange.

Unfortunately, while changing the flange, all of a sudden a mixture of hot water and steam started leaking through the flange. The steam jet of hot water/ steam hit the fitter on chest and stomach.

The 3rd engineer managed to move away from the jet of hot water and steam; however, the fitter was not able to move quickly as he had buckled the belt to a bracket. By the time he could unbuckle the belt, it was already too late and the damage had been done.

Later the leakage was stopped, and the fitter was brought down. The fitter was severely burnt and in a state of shock. His boiler suit was badly stuck to his body because of severe skin burns. The 3rd engineer also got burns on one of his leg and arms. Both were taken to a hospital ashore.

It was later revealed that the fitter’s lungs and kidney were severely affected because of the steam burns. The fitter died after 3 months. The 3rd engineer was also badly affected and had to stay in the hospital for around 3-4 months. Fortunately, the 3rd engineer survived.

Conclusion

This is an extremely unfortunate accident which could have been averted if proper precautions had been taken before opening the flange. Dealing with steam on board ship is a dangerous task, and seafarers must take all the necessary measures that are required before getting involved with such work.

Image credits : captainsvoyage-forum

About Author

Raunek Kantharia is a marine engineer turned maritime writer and entrepreneur. After a brief stint at the sea, he founded Marine Insight in 2010. Apart from managing Marine Insight, he also writes for a number of maritime magazines and websites.

Do you have info to share with us ? Suggest a correction

- Real Life Incident: Vessel Collision in Good Visibility

- Real Life Incident: Severe Injury To Deck Crew While Leaving Berth

- Real Life Incident: Departure Damage in Very Restricted Waterway

- Real Life Incident: Low Situational Awareness Has High Impact Consequence

- Real Life Incident: Fouled Anchor in a Designated Anchorage

- Real Life Incident: Fire On Barge Carrying Scrap Metal Causes $7 Million Worth Of Damage

Latest Case studies Articles You Would Like:

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Web Stories

Safety measures must be carried out when working with boiler pipe exhaust gas economizer, first stop boiler water circulating pump, close in and out valves for boiler water circulating pump, stop boiler burner, keep feed pump running, release all boiler pressure until 0 kg/cm2, using excess steam valve setpoint to 0, returning steam to boiler condenser, open all heating steam to fuel tanks, this will reduce the pressure to minimun, then stop feed pump, close main steam boiler valve

Now, ensuring no pressure, the fitter and 3rd enginner can replace a gasket.

Whilst I agree with what was said by Ivan, I feel that one very important point has been left out and this applies with ANY pipework system. Always, but always, loosen flange nuts and bolts two or three turns before splitting the flange. Once the flange joint has been split and everything is okay remove nuts and bolts from the flange. If someting unforeseen does happen the leakage is controlled and the flange may be able to be re-tightened and the pressure relieved, before resuming work on the system..

I was taught to do this over 60 years ago and I teach and have taught my studentds in marine engineering to do the same………..it works well.