Real Life Incident: Fourth Engineer Suffers Serious Hand Injury – Fingertip Severed

Whilst attempting to lower the purifier bowl assembly on to its overhauling stand, the fourth engineer’s left index finger got trapped between the bowl and the upper surface of the workbench. The tip of the finger was severed.

Result of investigation

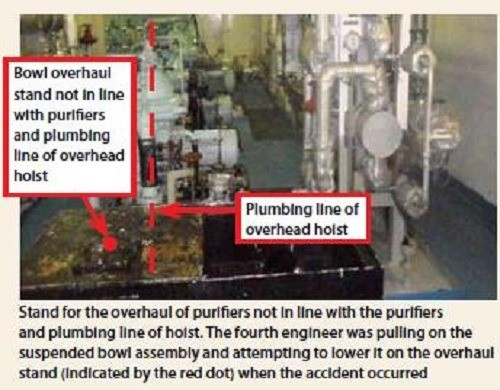

1 The overhead rail of the traveling chain hoist was not vertically above the bowl overhauling stand, requiring the user to pull on the suspended bowl assembly and guide it into the stand manually. This increased the risk of injury to fingers;

2 Although a routine risk assessment was carried out before commencing the task, it was too generic in nature and did not address the specific hazards and risks involved in the operation;

3 Sufficient number of crew were assigned for the job;

4 The fourth engineer was fully fit, alert, sufficiently rested and wearing appropriate personal protective equipment (PPE). He had previously served on the same vessel in the past and was fully conversant with routine tasks;

5 Although the stand had been wrongly positioned ever since the vessel was commissioned, no modification request was raised by ship’s staff;

6 None of the crew assigned to the task recognised the obvious danger arising from the wrong working practice employed – i.e. positioning a large, heavy object by hand whilst it is being lowered;

7 There appeared to be a training gap on board – no senior engineer or rating had coached the young fourth engineer on safe working practices;

8 The same arrangements in the purifier room of a sister vessel were correct in all respects with the hoist plumbing the purifiers and the overhauling stand.

Corrective action

1 After the accident, the overhauling stand was properly aligned to be in line with the chain hoist and purifiers;

2 Fleet circular issued instructing all vessels to discuss the incident at the next safety meeting;

3 Officers ashore will be briefed on this incident by:

i. Seminars conducted by the DPA;

ii. During pre-joining briefing with the superintendents;

iii. New officers joining the company will be briefed in detail during their familiarisation training in the office;

4 The knowledge, understanding and proper implementation of safe working practices will be verified during internal audits and other visits on board by the superintendents.

Lessons learnt

1 This accident shows again the value of conducting proper risk assessments and the importance of coaching of junior officers.

2 Toolbox meetings must be held with all crew related to each task. Risks and precautions shall be discussed and understood well by all assigned to the task.

Reference & Image Credits: nautinst

Do you have info to share with us ? Suggest a correction

- Real Life Incident: Vessel Collision in Good Visibility

- Real Life Incident: Severe Injury To Deck Crew While Leaving Berth

- Real Life Incident: Departure Damage in Very Restricted Waterway

- Real Life Incident: Low Situational Awareness Has High Impact Consequence

- Real Life Incident: Fouled Anchor in a Designated Anchorage

- Real Life Incident: Fire On Barge Carrying Scrap Metal Causes $7 Million Worth Of Damage

Latest Case studies Articles You Would Like:

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Hello search for job

possible maintenance technician Help